Genetic improvement of processes yielding microbial products

Jose L. Adrio1 & Arnold L. Demain2

1

Department of Biotechnology, Puleva Biotech, S.A., Granada, Spain; and 2Charles A. Dana Institute for Scientists Emeriti, Drew University, Madison, NJ, USA

Correspondence: Jose L. Adrio, Department

of Biotechnology, Puleva Biotech, S.A.,

Camino de Purchil, 66, 18004 Granada,

Spain. Tel.:134 958 24 02 27; fax:134 958

24 01 60; e-mail: jladrio@pulevabiotech.es

Received 3 March 2005; revised 18 August

2005; accepted 19 August 2005

First published online 17 October 2005.

Although microorganisms are extremely good in presenting us with an amazing

array of valuable products, they usually produce them only in amounts that they

need for their own benefit; thus, they tend not to overproduce their metabolites. In

strain improvement programs, a strain producing a high titer is usually the desired

goal. Genetics has had a long history of contributing to the production of

microbial products. The tremendous increases in fermentation productivity and

the resulting decreases in costs have come about mainly by mutagenesis and

screening/selection for higher producing microbial strains and the application of

recombinant DNA technology.

Editor: Alexander Boronin

Keywords

strain improvement; genetic recombination;

primary metabolites; secondary metabolites;

directed evolution; combinatorial biosynthesis.

Introduction

Microorganisms can generate new genetic characters (‘genotypes’) by two means: mutation and genetic recombination. In

mutation, a gene is modified either unintentially (‘spontaneous mutation’) or intentially (‘induced mutation’).

Although the change is usually detrimental and eliminated by

selection, some mutations are beneficial to the microorganism. Even if it is not beneficial to the organism, but beneficial

to humans, the mutation can be detected by screening and can

be preserved indefinitely. This is indeed what the fermentation

microbiologists did in the strain development programs that

led to the great expansion of the fermentation industry in the

second half of the twentieth century.

It was fortunate that the intensive development of microbial genetics began in the 1940s when the fermentative

production of penicillin became an international necessity.

The early studies in basic genetics concentrated on the

production of mutants and their properties. The ease with

which ‘permanent’ characteristics of microorganisms could be

changed by mutation and the simplicity of the mutation

techniques had tremendous appeal to microbiologists. Thus

began the cooperative ‘strain-selection’ program among workers at the U.S. Department of Agriculture Laboratories in

Peoria, the Carnegie Institution, Stanford University and the

University of Wisconsin, followed by the extensive individual

FEMS Microbiol Rev 30 (2006) 187–214

programs that still exist today in industrial laboratories

throughout the world. It is clear that mutation has been the

major factor involved in the hundred- to thousand-fold

increases obtained in production of microbial metabolites

and that the ability to modify genetically a microbial culture

to higher productivity has been the most important factor in

keeping the fermentation industry in its viable, healthy state.

Applications of mutation

Mutation has improved the productivity of industrial cultures (Vinci & Byng, 1999; Parekh et al., 2000). It has also

been used to shift the proportion of metabolites produced in

a fermentation broth to a more favorable distribution,

elucidate the pathways of secondary metabolism, yield new

compounds, and for other functions. The most common

method used to obtain high yielding mutants is to treat a

population with a mutagenic agent until a certain ‘desired’

kill is obtained, plate out the survivors and test each

resulting colony or a randomly selected group of colonies

for product formation in flasks. The most useful mutagens

include nitrosoguanidine (NTG), 4-nitroquinolone-1oxide, methylmethane sulfonate (MMS), ethylmethane sulfonate (EMS), hydroxylamine (HA) and ultraviolet light

(UV). The optimum level of kill for increased production of

antibiotics is thought to be in the range 70–95% (Simpson &

2005 Federation of European Microbiological Societies

Published by Blackwell Publishing Ltd. All rights reserved

c

Downloaded from http://femsre.oxfordjournals.org/ by guest on March 5, 2016

doi:10.1111/j.1574-6976.2005.00009.x

Abstract

188

Mutants producing increased quantites of

metabolites

Genetics has had a long history of contributing to the production of microbial products. The tremendous increases in

fermentation productivity and the resulting decreases in costs

have come about mainly by mutagenesis and screening for

higher producing microbial strains. At least five different classes

of genes control metabolite production (Malik, 1979): (i)

structural genes coding for product synthases, (ii) regulatory

genes determining the onset and expression of structural genes,

(iii) resistance genes determining the resistance of the producer

to its own antibiotic, (iv) permeability genes regulating entry,

exclusion and excretion of the product, and (v) regulatory

genes controlling pathways providing precursors and cofactors.

Overproduction of microbial metabolites is effected by (i)

increasing precursor pools, (ii) adding, modifying or deleting

regulatory genes, (iii) altering promoter, terminator and/or

regulatory sequences, (iv) increasing copy number of genes

encoding enzymes catalyzing bottleneck reactions, and (v)

removing competing unnecessary pathways (Strohl, 2001).

It is now over 60 years since the first superior penicillinproducing mutant, Penicillium chrysogenum X-1612, was

isolated afer X-ray mutagenesis. This heralded the beginning

of a long and successful relationship between mutational

genetics and industrial microbiology (Hersbach et al., 1984).

The improvement of penicillin production by conventional

strain improvement resulted both from enhanced gene

expression and from gene amplification (Barredo et al.,

1989; Smith et al., 1989). Increased levels of mRNA corresponding to the three enzymes of penicillin G biosynthesis

were found in high-penicillin producing strains of P. chrysogenum as compared to wild-type strains (Smith et al.,

2005 Federation of European Microbiological Societies

Published by Blackwell Publishing Ltd. All rights reserved

c

1990). High-producing strains contained an amplified region; a 106-kb region amplified five to six times as tandem

repeats was detected in a high-producing strain, whereas

wild-type P. chrysogenum and Fleming’s original strain of

P. notatum contained only a single copy (Fierro et al., 1995).

Strain improvement has been the main factor involved in

the achievement of impressive titers of industrial metabolites.

The production titer of tetracycline as far back as 1979 was

reported to be over 20 g L 1 (Podojil et al., 1984), mainly due

to strain improvement. Later, titers of 30–35 g L1 were

reached for chlortetracycline and tetracycline. The production

titer of penicillin is 70 g L 1 and that of cephalosporin C over

30 g L 1 (Elander, 2003). The production titer of tylosin has

been reported to be over 15 g L1 (Chen et al., 2004) and that

of salinomycin is 60 g L 1 (Liu, 1982).

Morphological and pigment mutants

Although almost nothing is known about the mechanisms

causing higher production in superior random or morphological mutants, it is likely that many of these mutations involve

regulatory genes, especially as regulatory mutants obtained in

basic genetic studies are sometimes found to be altered in

colonial morphology. Thus, morphological mutants have been

very important in strain improvement. These include mutants

affected in mycelia formation, which produce colonies with a

modified appearance or a new color. Color changes have also

been important for pigment producers (Table 1).

Auxotrophic mutants

Very early in the development of the concepts of regulation,

geneticists realized that the end product of a biosynthetic

pathway to a primary metabolite excercises strict control

over the amount of an intermediate accumulated by an

auxotrophic mutant of that pathway. Only at a growthlimiting concentration of the end product would a large

accumulation of the substrate of the deficient enzyme occur.

This principle of decreasing the concentration of an inhibitory or repressive end product to bypass feedback inhibition

or repression was best accomplished by the use of auxotrophic mutants. Indeed, auxotrophic mutation has been a

major factor in the industrial production of primary products such as amino acids and nucleotides (Table 1). The

production of secondary products such as antibiotics is also

markedly affected by auxotrophic mutation, even when

auxotrophs are grown in nutritionally complete and even

complex media. Although the change in product formation

is usually in the negative direction, higher-producing auxotrophs are obtained from producers of antibiotics.

When several primary metabolites are produced by a

single branched pathway, mutation in one branch of the

pathway often leads to overproduction of the product of the

FEMS Microbiol Rev 30 (2006) 187–214

Downloaded from http://femsre.oxfordjournals.org/ by guest on March 5, 2016

Caten, 1979), although some industrial programs use much

higher levels, e.g. up to 99.99%. It is incorrect to condemn a

mutation and screening procedure because, on average, it

decreases production ability; indeed, this is the case for

successful mutagenesis. One should only be interested in the

frequency of improved mutants.

Although single cells or spores are preferred for mutagenesis, non-spore-forming filamentous organisms have been

mutated successfully by mutagenizing mycelia, preparing

protoplasts and regenerating on solid medium (Keller,

1983). Sonication is sometimes used to break up Streptomyces mycelia after mutagenesis and before screening for

improved mutants (Takebe et al., 1989). Poorly sporulating

filamentous organisms can be mutagenized after fragmentation or formation of protoplasts (Kim et al., 1983; Kurzatkowski et al., 1986).

More detailed information can be found in several authorative reviews on genetics and especially on mutation in actinomycetes (Baltz, 1986, 1995, 1998, 1999; Hopwood, 1999).

J. L. Adrio & A. L. Demain

189

Genetic improvement of processes yielding microbial products

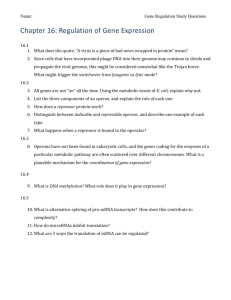

Table 1. Mutations leading to increased product formation

Mutation type

Organism

5.7. Ashbya gossypii

5.8. Penicillium

chrysogenum

5.9. Amycolatopsis

mediterranei

6. Product resistance

6.1 Streptomyces

goldiniensis

6.2. Nocardia

uniformis

6.3. Streptomyces

kitasatoensis

6.4. Streptomyces

rimosus

7. Antibiotic resistance 7.1 Streptomyces

coelicolor and

Streptomyces lividans

FEMS Microbiol Rev 30 (2006) 187–214

Overproduced

compound

Reference

Wrinkled colonies

Histidine

Roth & Ames (1966)

‘Bald colonies’; then white colonies

Daunorobicin

Blumauerova et al. (1978)

Reddish-orange colonies with no

aerial mycelia

Pink colonies on agar containing

b-ionone or diphenylamine

Pink instead of brown mycelia

Beromycins

Blumaerova et al. (1980, 1980)

Astaxanthin

Lewis et al. (1990);

Chumpolkulwong et al. (1997)

Lee et al. (2003)

Guanine auxotrophy

Leucine auxotrophy

Leucine auxotrophy

Teichoplanins

5 0 -Inosinic acid (IMP)

and hypoxanthine

Bacitracin

Teshiba & Furuya (1983)

Haavik & Froyshov (1982)

Non-auxotrophic for aspartate

Cephamycin C and

penicillin N

Tylosin

Godfrey (1973)

Lee & Lee (1995)

Producing ability

Chlortetracycline

Dulaney & Dulaney (1967)

Producing ability

Aurodox

Unowsky & Hoppe (1978)

Resistance to ethionine

Methionine

Tani et al. (1988)

Resistance to thialysine

Cephamycins

Resistance to thialysine

Desferrioxamine

Mendelovitz

& Aharonowitz (1983)

Smith (1987)

Resistance to 2-ketobutyrate in

presence of valine or isoleucine

Resistance to valine hydroxamate

Monensins A & B

Pospisil et al. (1999)

Teichoplanins

Resistance to iron, to tubercidin,

to 2-DOG

Resistance to itaconic acid and

aminomethylphosphinic acid

Resistance to phenylacetic acid

(precursor)

Sequential resistance to tryptophan

(feedback inhibitor), phydroxybenzoate, and propionate

(precursor)

Resistance to aurodox

Riboflavin

Wang et al. (1996);

Jin et al. (2002a)

Stahmann et al. (2000)

Riboflavin

Stahmann et al. (2000)

Penicillin G

Barrios-Gonzalez et al. (1993)

Rifamycin B

Jin et al. (2002)

Aurodox

Unowsky & Hoppe (1978)

Resistance to nocardicin

Nocardicin

Elander & Aoki (1982)

Resistance to leucomycin

Leucomycin

Higashide (1984)

Resistance to oxytetracycline

Oxytetracycline

Gravius et al. (1994)

Resistance to streptomycin,

gentamicin, paromomycin,

rifamycin and combinations

Actinorhodin

Hosoya et al. (1998); Hesketh

& Ochi (1997); Okamoto et al.

(2003); Okamoto-Hosoya et al.

2000; Hu & Ochi (2001)

2005 Federation of European Microbiological Societies

Published by Blackwell Publishing Ltd. All rights reserved

c

Downloaded from http://femsre.oxfordjournals.org/ by guest on March 5, 2016

1. Morphological and/ 1.1. Salmonella

or pigment change typhimurium

1.2. Streptomyces

coeruleorubidus

1.3. Streptomyces

glomeratus

1.4. Phaffia

rhodozyma

1.5. Actinoplanes

teichomyceticus

2. Auxotrophic

2.1. Brevibactetrium

ammoniagenes

2.2. Bacillus

licheniformis

2.3. Streptomyces

lipmanii

3. Reversion of

3.1. Streptomyces

auxotrophy

fradiae

4. Reversion of

4.1. Streptomyces

non-production

viridifaciens

4.2. Streptomyces

goldiniensis

5. Antimetabolite

5.1. Candida boidinii

resistance

5.2. Streptomyces

clavuligerus

5.3. Streptomyces

pilosus

5.4. Streptomyces

cinnamonensis

5.5. Actinoplanes

teichomyceticus

5.6. Candida flareri

Mutant characteristics

190

J. L. Adrio & A. L. Demain

Table 1. Continued.

Overproduced

compound

Organism

Mutant characteristics

8. Reversal of carbon

source repression

8.1. Saccharomyces

cerevisiae

8.2. Schwanniomyces

castelli

8.3. Pichia

polymorpha

8.4. Penicillium

chrysogenum

8.5 Aspergillus niger

8.6. Aspergillus niger

9.1. Streptomyces

aureofaciens

9.2. Streptomyces

griseus

10.1. Acremonium

chrysogenum

10.2. Streptomyces

viridifaciens

10.3. Bacillus subtilis

10.4. Aspergillus

nidulans

10.5. Aspergillus niger

10.6. Rhyzopus oryzae

10.7. Streptomyces

kasugaensis

10.8. Acremoniums

chrysogenum

10.9. Streotomyces

hygroscopicus

11.1. Brevibacterium

flavum

11.2. Brevibacterium

ammoniagenes

11.3. Escherichia coli

11.4. Corynebacterium

glutamicum

Resistance to 2-deoxyglucose

9. Reversal of

phosphate inhibition

10. Increased

production on agar

11. Change in

permeability

Resistance to 2-deoxyglucose

Cheese whey

hydrolysis

Isomaltase, amylase

Resistance to 2-deoxyglucose

Inulinase

McCann & Barnett (1984);

Sills et al. (1984)

Bajon et al. (1984)

Resistance to 2-deoxyglucose

Penicillin G

Chang et al. (1980)

Rapid growth on high sucrose

Resistance to 2-deoxyglucose

Small colonies on phosphate-limiting

agar

Production in excess-phosphate

medium

Increased clear zone around colony

Citric acid

Citric acid

Tetracycline

Schreferl-Kunar et al. (1989)

Kirimura et al. (1992)

Colombo et al. (1981)

Candicidin

Martin et al. (1979)

Cephalosporin C

Elander (1969)

Increased clear zone around colony

Chlortetracycline

Dulaney & Dulaney (1967)

Increased clear zone around colony

Increased clear zone around colony

Mycobacillin

Penicillin

Bannerjee & Bose (1964)

Ditchburn et al. (1974)

Increased clear zone around colony

Increased clear zone around colony

Increased clear zone around plugs

of agar

Increased clear zone around plugs

of agar

Increased clear zone around plugs

of agar

Inability to grow on glutamate

Citric acid

Lactate

Kasugamycin

Das & Roy (1981)

Longacre et al. (1997)

Ichikawa et al. (1971)

Cephalosporin C

Chang & Elander (1979)

Complex ‘165’

Gesheva (1994)

Glutamic acid

5 0 -Inosinic acid

Shiio et al. (1982); Mori

& Shiio (1983)

Teshiba & Furuya (1983)

Proline

Tryptophan

Rancount et al. (1984)

Ikeda & Katsumata (1995)

Increased sensitivity to deoxycholate

and lysozyme

Elimination of active praline uptake

Decrease in tryptophan uptake

other branch. Examples include the overproduction of

phenylalanine by tyrosine auxotrophs and vice versa, and

the overproduction of lysine by auxotrophs requiring threonine and methionine. In the case of branched pathways

leading to a primary metabolite and a secondary metabolite,

auxotrophic mutants requiring the primary metabolite

sometimes overproduce the secondary metabolite (Table 1).

Reversion of an auxotroph to prototrophy sometimes

leads to new prototrophs possessing higher enzyme activity

than present in the original ‘grandparent’ prototroph. Such

increased enzyme activity was probably the result of a

structural gene mutation producing a more active enzyme

or an enzyme less subject to feedback inhibition (Table 1).

Revertants of non-producing mutants

A high proportion of such mutants has been found to

produce increased amounts of antibiotics (Table 1).

2005 Federation of European Microbiological Societies

Published by Blackwell Publishing Ltd. All rights reserved

c

Reference

Bailey et al. (1982)

Antimetabolite-resistant mutants

Basic studies on regulation have shown that it is possible to

select regulatory mutants, which overproduce the end

products of primary pathways, using toxic metabolite analogues. Such antimetabolite-resistant mutants often possess

enzymes that are insensitive to feedback inhibition, or

enzyme-forming systems resistant to feedback repression.

The selection of mutants resistant to toxic analogues of

primary metabolites has been widely employed by industrial

microbiologists (Table 1).

A variation of the antimetabolite selection techniques is

possible when a precursor is toxic to the producing organism. The principle here is that the mutant most capable of

detoxifying the precursor by incorporating it into the

antibiotic will be the best grower in the presence of the

precursor (Table 1). When the secondary metabolite

FEMS Microbiol Rev 30 (2006) 187–214

Downloaded from http://femsre.oxfordjournals.org/ by guest on March 5, 2016

Mutation type

191

Genetic improvement of processes yielding microbial products

produced is itself a growth inhibitor of the producing

culture, as in the case of certain antibiotics, the metabolite

can sometimes be used to select resistant mutants that are

improved producers.

Certain streptomycin resistance mutations cause increased production of unrelated antibiotics. In addition to

improvement in secondary metabolite formation by mutation to streptomycin resistance, resistance to gentamicin or

to paromomycin is even more effective. Furthermore,

triple mutation to resistance to streptomycin, gentamicin

and rifampicin, each of which individually increased actinorhodin formation, was found to be the most effective

(Table 1).

Mutants resistant to nutritional repression

Improved production on agar

In many cases, fermentation performance on an agar plate is

related to production in submerged liquid culture, and the

method has application as a means of detecting superior

mutants. So-called ‘zone mutants’ have proven useful for

improving several different processes (Table 1).

A widely used modification involves the production of

antibiotics by colonies on separate plugs of agar followed by

placement of these plugs on a seeded assay plate and

measurement of the resultant clear zones. The use of this

‘agar piece method’ resulted in improvement of antibiotic

production (Table 1). Agar-piece screening of antibiotic

production in the presence of inhibitory levels of phosphate

(15 mM) led to the isolation of six markedly improved and

stable Streptomyces hygroscopicus strains producing the

macrolide antifungal complex ‘165’ (Gesheva, 1994).

Permeability mutants

Product excretion in overproducing strains often occurs

when uptake and/or catabolism is impaired. Thus, genetic

lesions eliminating active uptake can be used to specifically

enhance excretion of metabolites (Table 1). It is often of

benefit to isolate mutants unable to grow on the

FEMS Microbiol Rev 30 (2006) 187–214

Mutants showing qualitative changes in the mix

of fermentation products

As many organisms produce secondary metabolites as

mixtures of a chemical family or of several chemical families,

mutation has been used to eliminate undesirable products in

such fermentations. An example is that of Nakatsukasa and

Mabe (Nakatsukasa & Mabe, 1978), who found that streaking out a natural single colony isolate from Streptomyces

aureofaciens (producing the polyether narasin and the

broad-spectrum antibiotic enteromycin) on galactose led to

yellow and white sectoring. The effect was specific for

galactose. Of the four colony types obtained, one produced

only narasin and two produced only enteromycin.

Streptomyces griseus ssp. cryophilus makes four R3 sulfated

and four R3 unsulfated carbapenems. The sulfated forms are

less active than the unsulfated forms. To completely eliminate

the R3 sulfated forms, sulfate transport mutants were obtained. These were of two types: (i) auxotrophs for thiosulfate

or cysteine; and (ii) selenate-resistant mutants. Each type

produced completely unsulfated forms and titers were equivalent to the total titer of the parent (Kitano et al., 1985).

Eight avermectins are produced by Streptomyces avermitilis, of which only a small number are desirable. A nonmethylating mutant produced only four of the compounds

and a mutant that failed to make the 25-isopropyl substituent (from valine) produced a different mixture of components. By protoplast fusion, a hybrid strain was obtained

which made only two components, B2a and B1a (Omura

et al., 1991). Stutzman-Engwall and colleagues (StutzmanEngwall et al., 2003) introduced random mutations by PCR

into gene aveC and obtained a mutant that produced an

avermectin B1 : B2 ratio of 2.5, much improved over the 0.6

ratio of the parent S. avermitilis strain.

Mutation was used to eliminate the undesirable polyketides sulochrin and asterric acid from broths of the lovastatin producer, Aspergillus terreus (Vinci et al., 1991). Mutants

have also been employed to eliminate undesirable coproducts from the monensin fermentation (Pospisil et al.,

1984).

Mutants producing new antibiotics

Mutant methodology has been used to produce new molecules. The medically useful products demethyltetracycline

2005 Federation of European Microbiological Societies

Published by Blackwell Publishing Ltd. All rights reserved

c

Downloaded from http://femsre.oxfordjournals.org/ by guest on March 5, 2016

Nutritional repression can also be decreased by mutation to

antimetabolite resistance. Examples of selection agents are

2-deoxyglucose (2-DOG) for enzymes and pathways controlled by carbon source regulation (Table 1), methylammonium for those regulated by nitrogen source repression, and

arsenate for phosphate regulation.

Mutants that use phosphate less efficiently for growth

sometimes show improved antibiotic production. Thus,

screening for small colonies on phosphate-limiting media

could be a useful strain improvement technique for phosphate-regulated products (Table 1).

desired product as sole carbon or energy source. Such

mutants are often impaired in their ability to takeup the

product and they contain lower intracellular levels of the

product, thus lessening feedback regulation. In certain

improved mutants, there is an increase in sensitivity

to deoxycholate and lysozyme, indicating a change in

permeability.

192

Use of mutants to elucidate biosynthetic

pathways

A further use of mutants has been the elucidation of

metabolic pathways. This has been exploited for the biosynthesis of tetracyclines (McCormick, 1965), novobiocin

(Kominek, 1972), erythromycin (Martin et al., 1966;

Martin & Rosenbrook, 1967), neomycin (Pearce et al.,

1978), tylosin (Baltz et al., 1983), other aminoglycosides

(Penzikova & Levitov M, 1970; Takeda et al., 1978; Fujiwara

et al., 1980; Kase et al., 1982; Hanssen & Kirby, 1983),

rosaramicin (Vaughn et al., 1982), daunorubicin (McGuire

et al., 1981), other anthracyclines (Motamedi et al., 1986;

Yue et al., 1986), actinomycin (Troost & Katz, 1979),

carbapenems (Nozaki et al., 1984; Kojima et al., 1988),

ansamycins (Kibby et al., 1980; Ghisalba et al., 1981),

patulin (Gaucher et al., 1981) and phenazines (Byng et al.,

1979).

2005 Federation of European Microbiological Societies

Published by Blackwell Publishing Ltd. All rights reserved

c

Genetic recombination

In contrast to the extensive use of mutation in industry, genetic

recombination was not much used at first, despite early claims

of success (Jarai, 1961; Mindlin, 1969), mainly due to the

absence or the extremely low frequency of genetic recombination in industrial microorganisms (in streptomycetes, it was

usually 106 or even less). Other problems were evident with

the b-lactam-producing fungi. Although Aspergillus exhibited

sexual and parasexual reproduction, the most commercially

interesting genera, Cephalosporium and Penicillium, were the

most difficult to work with as they only reproduced parasexually, which rarely resulted in recombination.

Recombination was erroneously looked upon as an alternative to mutation instead of a method that would complement mutagenesis programs. The most balanced and

efficient strain development strategy would not emphasize

one to the exclusion of the other; it would contain both

mutagenesis-screening and recombination-screening components. In such a program, strains at different stages of a

mutational line, or from lines developed from different

ancestors, would be recombined. Such strains would no

doubt differ in many genes and by crossing them, genotypes

could be generated which would never occur as strictly

mutational descendants of either parent. Recombination

was also of importance in the mapping of production genes.

Studies on the genetic maps of overproducing organisms

such as actinomycetes are relatively recent. The model for

such investigations was the genetic map of Streptomyces

coelicolor (Kieser et al., 1992), which was found to be very

similar to those of other Streptomyces species, such as

S. bikiniensis, S. olivaceous, S. glaucescens and S. rimosus.

Protoplast fusion

As mentioned above, genetic recombination was virtually

ignored in industry, mainly due to the low frequency of

recombination. However, use of protoplast fusion changed

the situation markedly. After 1980, there was a heightened

interest in the application of genetic recombination to the

production of important microbial products such as antibiotics. Today, frequencies of recombination have increased to

even greater than 101 in some cases (Ryu et al., 1983), and

strain improvement programs routinely include protoplast

fusion between different mutant lines. The power of recombination was demonstrated by Yoneda (Yoneda, 1980), who

recombined individual mutations, each of which increased aamylase production by two- to seven-fold in Bacillus subtilis.

A strain constructed by genetic transformation, which contained all five mutations, produced 250-fold more a-amylase.

Recombination is especially useful when combined with

conventional mutation programs to solve the problem of

‘sickly’ organisms produced as a result of accumulated

genetic damage over a series of mutagenized generations.

FEMS Microbiol Rev 30 (2006) 187–214

Downloaded from http://femsre.oxfordjournals.org/ by guest on March 5, 2016

and doxorubicin were discovered by simple mutation of

the cultures producing tetracycline and daunorubicin,

respectively. Later, the technique of ‘mutational biosynthesis’ (= mutasynthesis) was devised (Shier et al., 1969). In

this process, a mutant blocked in secondary metabolism is

fed analogs of the moiety whose biosynthesis is blocked. If

successful, the mutant (called an ‘idiotroph’) produces a

new antibiotic derivative (Nagaoka & Demain, 1975). The

hybramycins were the first compounds to be made this way

(Shier et al., 1969). Since then, mutational biosynthesis has

been used for the discovery of many new secondary metabolites (Lemke & Demain, 1976; Daum & Lemke, 1979;

Kitamura et al., 1982). The most well-known is the commercial antihelmintic agent doramectin, the production

of which employed a mutant of the avermectin producer

S. avermitilis (Cropp et al., 2000).

New anthracyclines and aglycones have been isolated

from blocked mutants of the daunorubicin and doxorubicin

producers (Cassinelli et al., 1980; McGuire et al., 1981). By

adding carminomycinone or 13-dihydrocarminomycinone

to an idiotroph of Streptomyces galilaeus (the producer of

aclacinomycin), the aglycones were glycosylated to form a

new trisaccharide anthracycline, trisarubicionol (Yoshimoto

et al., 1981).

New macrolide antibiotics have been produced from

blocked mutants of the tylosin-producer, Streptomyces fradiae (Kirst et al., 1983). Four new hybrid macrolide antibiotics were obtained by feeding erythronolide B to a

blocked mutant of the oleandomycin producer, Streptomyces

antibioticus (Spagnoli et al., 1983). A blocked-mutant of the

mycinamicin producer, Micromonospora polytrota, was fed

various rosaramicin precursors and converted them into

new rosaramicins (Lee et al., 1983).

J. L. Adrio & A. L. Demain

193

Genetic improvement of processes yielding microbial products

FEMS Microbiol Rev 30 (2006) 187–214

flocculation (Panchal et al., 1982), lactose utilization (Farahnak et al., 1986), the killer character (Bortol et al., 1986;

Farris et al., 1992), cellobiose fermentation (Pina et al.,

1986) and methionine overproduction (Brigidi et al., 1988).

Plasmids, transposons, cosmids and phage

Plasmid DNA has been detected in virtually all antibioticproducing species of Streptomyces. Some are sex plasmids

and constitute an essential part of the sexual recombination

process and others contain either structural genes or genes

somehow influencing the expression of the chromosomal

structural genes of antibiotic biosynthesis.

Most plasmids have no apparent effect on metabolite

production and only very few antibiotic biosynthesis processes are encoded by plasmid-borne genes. However, the

production of methylenomycin A is encoded by genes

present on plasmid SCP1 in Streptomyces coelicolor. When

the plasmid was transferred to other streptomycetes, the

recipients produced the antibiotic. For many years, plasmid

SCP1 was never observed or isolated as a circular DNA

molecule, because it was a giant linear plasmid. It was

initially difficult to separate such giant linear plasmids from

chromosomal DNA but this was later accomplished by

pulsed field gel electrophoresis or orthogonal field alteration

gel electrophoresis (OFAGE) (Kinashi & Shimaji, 1987).

Some products of unicellular bacteria are plasmid-encoded. These include aerobactin, a hydroxamate siderophore

and virulence factor produced by Escherichia coli (McDougall

& Neilands, 1984) and other Gram-negative bacteria (Enterobacter aerogenes, Enterobacter cloacae, Vibrio mimicus, and

species of Klebsiella, Salmonella and Shigella). Aerobactin is

synthesized by a plasmid-borne five-gene cluster, which is

negatively regulated by iron (Roberts et al., 1986); it can also

be produced via chromosomal genes (Moon et al., 2004). It

also appears that siderophore production by Arizona hinshawii is plasmid-encoded. A microcin, an antimetabolite of

methionine, which is produced by E. coli and acts as a

competitive inhibitor of homoserine-O-transuccinylase, is

encoded by a plasmid that occurs at 20 copies per genome

equivalent (Perez-Diaz & Clowes, 1980). The gene coding for

the parasporal crystal body (d-endotoxin) of Bacillus thuringiensis is plasmid-borne (Whiteley & Schnepf, 1986; De

Maagd et al., 2003) in most species but is on the chromosome in a few other species.

Instability in Streptomyces is brought about by environmentally stimulated macrolesions, e.g. deletions, transpositions, rearrangements and DNA amplification. They occur

spontaneously or are induced by environmental stresses

such as intercalating dyes, protoplast formation and regeneration, and interspecific protoplast fusion. Streptomycetes

are the only prokaryotes known to be subject to spontaneous

DNA amplification, sometimes amounting to several

2005 Federation of European Microbiological Societies

Published by Blackwell Publishing Ltd. All rights reserved

c

Downloaded from http://femsre.oxfordjournals.org/ by guest on March 5, 2016

For example, a cross via protoplast fusion was carried out

with strains of Cephalosporium acremonium from a commercial strain improvement program. A low-titer, rapidly-growing, spore-forming strain which required methionine to

optimally produce cephalosporin C was crossed with a

high-titer, slow-growing, asporogenous strain which could

use the less expensive inorganic sulfate. The progeny included a recombinant which grew rapidly, sporulated, produced cephalosporin C from sulfate and made 40% more

antibiotic than the high-titer parent (Hamlyn & Ball, 1979).

Protoplast fusion was used to modify the characteristics

of an improved penicillin-producing strain of P. chrysogenum which showed poor sporulation and poor seed growth.

Backcrossing with a low-producing (12 g L1) strain yielded

a high-producing (18 g L 1) strain with better sporulation

and better growth in seed medium (Lein, 1986). Interspecific protoplast fusion between the osmotolerant Saccharomyces mellis and the highly fermentative S. cerevisiae yielded

stable hybrids fermenting high concentrations of glucose

(49% w w1) (Legmann & Margalith, 1983).

Another application of protoplast fusion is the recombination of improved producers from a single mutagenesis

treatment. By recombination, one could combine the yieldincrease mutations and obtain an even more superior

producer before carrying out further mutagenesis. Two

improved cephamycin-C producing strains from Nocardia

were fused and among the recombinants were two cultures

that produced 10–15% more antibiotic than the best parent

(Wesseling & Lago, 1981). Genetic recombination allows the

discovery of new antibiotics by fusing producers of different

or even the same antibiotics. A recombinant obtained from

two different rifamycin-producing strains of Nocardia mediterranei produced two new rifamycins (16,17-dihydrorifamycin S and 16,17-dihydro-17-hydroxy-rifamycin S) (Traxler et al., 1982). However, according to Hopwood

(Hopwood, 1983), these examples may reflect the different

expression of genes from parent A in the cytoplasm of parent

B, rather than the formation of hybrid antibiotics. Interspecific protoplast fusion between S. griseus and five other

species (Streptomyces cyaneus, Streptomyces exfoliatus, Streptomyces griseoruber, Streptomyces purpureus and Streptomyces

rochei) yielded recombinants of which 60% produced no

antibiotics and 24% produced antibiotics different from the

parent strains (Okanishi et al., 1996). New antibiotics can

also be created by changing the order of the genes of an

individual pathway in its native host (Hershberger, 1996).

A new antibiotic, indolizomycin, was produced by protoplast fusion between non-antibiotic producing mutants of

Streptomyces griseus and Streptomyces tenjimariensis (Gomi

et al., 1984). Osmotolerance of food yeasts such as

Saccharomyces cerevisiae and S. diastaticus was increased by

protoplast fusion with osmotolerant yeasts. Other traits

transferred between yeasts by protoplast fusion include

194

Improvement of microbial processes by

genetic engineering

Primary metabolites

New processes for the production of amino acids and

vitamins have been developed by recombinant DNA tech2005 Federation of European Microbiological Societies

Published by Blackwell Publishing Ltd. All rights reserved

c

nology. Escherichia coli strains were constructed with plasmids bearing amino acid biosynthetic operons. Plasmid

transformation was accomplished in Corynebacterium, Brevibacterium and Serratia and, as a result, recombinant DNA

technology has been used routinely to improve such commercial amino acid-producing strains (Sahm et al., 2000).

A recombinant strain of E. coli (made by mutating to

isoleucine auxotrophy, cloning in extra copies of the thrABC

operon, inactivating the threonine-degrading gene tdh, and

mutating to resistance to high concentrations of L-threonine

and L-homoserine) produced 80 g L1 L-threonine in 1.5

days at a yield of 50% (Eggeling & Sahm, 1999). Cloning

extra copies of threonine export genes into E. coli led to

increased threonine production (Kruse et al., 2002).

The introduction of the proline 4-hydroxylase gene from

Dactylosporangium sp. into a recombinant strain of E. coli

producing L-proline at 1.2 g L1 lead to a new strain producing 25 g L 1 of hydroxyproline (trans-4-hydroxy-L-proline) (Shibasaki et al., 2000). When proline was added,

hydroxyproline reached 41 g L1, with a yield of 87% from

proline.

An engineered strain of Corynebacterium glutamicum

producing 50 g L1 of L-tryptophan was further modified

by cloning in additional copies of its own transketolase gene

to increase the level of the erythrose-4-phosphate precursor

of aromatic biosynthesis (Ikeda & Katsumata, 1999). A low

copy number plasmid increased production to 58 g L1,

whereas a high copy number plasmid decreased production.

L-Valine production by mutant strain VAL1 of C. glutamicum amounted to 105 g L1 (Radmacher et al., 2002;

Lange et al., 2003). The mutant was constructed by overexpressing biosynthetic enzymes via a plasmid, eliminating

ilvA encoding threonine dehydratase, and deleting two genes

encoding enzymes of pantothenate biosynthesis. The culture

was grown with limitation of isoleucine and pantothenate.

By introduction of feedback-resistant threonine dehydratases and additional copies of genes encoding branched

amino and biosynthetic enzymes, lysine- or threonineproducing strains were converted into L-isoleucine producers with titers up to 10 g L1 (Morbach et al., 1996;

Guillouet et al., 1999; Hashiguchi et al., 1999). Amplification of the wild-type threonine dehydratase gene ilvA in a

threonine-producing strain of Corynebacterium lactofermentum led to 15 g L1 of isoleucine overproduction (Colon

et al., 1995).

Biotin has been made traditionally by chemical synthesis

but recombinant microbes have approached a competitive

economic position. The cloning of a biotin operon

(bioABFCD) on a multicopy plasmid allowed E. coli to

produce 10 000 times more biotin than did the wild-type

strain (Levy-Schil et al., 1993). Sequential mutation of

Serratia marcescens to resistance to the biotin antimetabolite

acidomycin (= actithiazic acid) led to mutant strain SB412,

FEMS Microbiol Rev 30 (2006) 187–214

Downloaded from http://femsre.oxfordjournals.org/ by guest on March 5, 2016

hundred tandem copies, accounting for over 10% of total

DNA, in the absence of selection. Amplification seems to be

coupled to DNA deletion and may involve insertion sequence (IS)-like elements (Baltz, 1986). Ethidium bromide

cures plasmids in streptomycetes but also increases the

frequency of deletion mutations, especially in areas of the

chromosome that are already unstable (Crameri et al., 1986).

Transposable elements, DNA sequences encoding a transposase enzyme (Berg & Berg, 1983) that move from one

replicon to another without host recombination functions

or extensive homology with the site of integration, have

been extremely useful for the following reasons: (i) they

usually provide stable, nonreverting mutants; (ii) they can

be used to determine the order of genes in an operon; (iii) it

is easy to select for mutants because transposons contain

antibiotic- or mercury-resistance markers; (iv) they provide

portable regions of homology for chromosomal mobilization; (v) they provide markers for non-selectable genes and

allow the cloning of such genes which can then be used as

hybridization probes to fish out the wild-type gene from a

genomic library; and (vi) they often have unique restriction

sites, and thus are good markers for isolating defined

deletion derivatives or locating the precise position of a gene

by heteroduplex mapping.

In the daptomycin producer Streptomyces roseosporus,

some Tn 5099 transposition mutants produced 57–66%

more daptamycin than the parent, whereas others produced

less or the same (McHenney & Baltz, 1996; Baltz et al., 1997).

Transposition increased the rate-limiting step of tylosin

biosynthesis in Streptomyces fradiae, i.e. the conversion of

macrocin to tylosin. Transposing a second copy of tylF into a

neutral site on the S. fradiae chromosome increased its gene

product, macrocin O-methyltransferase, and tylosin production, while decreasing the concentration of the final intermediate (macrocin). Tylosin production was increased by up

to 60% and the total macrolide titer was unchanged (Solenberg et al., 1996). Transposon mutagenesis eliminated the

production of the toxic oligomycin by the avermectinproducing Streptomyces avermitilis (Ikeda et al., 1993).

Cloning a 34-kb fragment from Streptomyces rimosus via a

cosmid into Streptomyces lividans and Streptomyces albus

resulted in oxytetracycline production by the recipients (Binnie et al., 1989). Contrary to earlier reports, all the oxytetracycline genes were clustered together on the S. rimosus

chromosomal map (Butler et al., 1989).

J. L. Adrio & A. L. Demain

195

Genetic improvement of processes yielding microbial products

FEMS Microbiol Rev 30 (2006) 187–214

Cloning of aldehyde dehydrogenase of Acetobacter polyoxogenes on a plasmid vector into Acetobacter aceti ssp.

xylinum increased the rate of acetic acid production by over

100% (1.8 g L1 h 1 to 4 g L 1 h1) and titer by 40%

(68 g L1 to 97 g L1) (Fukaya et al., 1989).

Genetic engineering of the inosine monophosphate

(IMP) dehydrogenase gene in a B. subtilis strain producing

7 g L1 of the desirable guanosine and 19 g L1 of the

undesirable inosine changed production to 20 g L 1 guanosine and 5 g L1 inosine (Miyagawa et al., 1986).

A recombinant E. coli strain was constructed that produced optically active pure D-lactic acid from glucose at

virtually the theoretical maximum yield, e.g. two molecules

from one molecule of glucose (Zhou et al., 2003). The

organism was engineered by eliminating genes of competing

pathways encoding fumarate reductase, alcohol/aldehyde

dehydrogenase and pyruvate formate lyase and by a mutation in the acetate kinase gene.

New technologies that have proven to be very useful for

increasing production of primary metabolites include genome-based strain reconstruction, metabolic engineering,

and whole genome shuffling (see section on Novel genetic

technologies).

Secondary metabolites

The application of recombinant DNA technology to the

production of secondary metabolites has been of great

interest (Baltz & Hosted, 1996; Diez et al., 1997). The tools

of the recombinant geneticist for increasing the titers of

secondary metabolites have included: (i) transposition mutagenesis, (ii) targeted deletions and duplications by genetic

engineering and (iii) genetic recombination by protoplast

fusion (Baltz, 2003). Recent additions to these techniques

include genomics, transcriptome analysis, proteomics, metabolic engineering, and whole genome shuffling (see section on Novel gene technologies).

One of the first indications that rDNA technology could

be applied to antibiotics and other secondary metabolites

was that it could be carried out in streptomycetes (Thompson et al., 1982). Plasmids were constructed from plasmid

SLP 1.2 of Streptomyces lividans and plasmid SCP2 from

Streptomyces coelicolor. In mating of plasmid-negative

S. lividans, ‘pocks’ (circular zones of sporulation inhibition

associated with plasmid transfer in the lawn of streptomycete growth arising from a regenerated protoplast population) were seen. This was due to looping out of a piece of S.

coelicolor DNA, which became a series of small S. lividans

plasmids (SLP 1.1 to 1.6) that were good cloning vehicles.

The genetic engineering of actinomycetes was limited for

a number of years by restriction barriers hindering DNA

introduction and by the inhibition of secondary metabolism

by self-replicating plasmid-cloning vectors (Baltz & Hosted,

2005 Federation of European Microbiological Societies

Published by Blackwell Publishing Ltd. All rights reserved

c

Downloaded from http://femsre.oxfordjournals.org/ by guest on March 5, 2016

which produced 20 mg L1 biotin (Sakurai et al., 1994).

Further improvements were made by mutating selected

strains to ethionine-resistance (strain ET2, 25 mg L1), then

mutating ET2 to S-2-aminoethylcysteine resistance (strain

ETA23, 33 mg L1) and finally cloning in the resistant bio

operon (Sakurai et al., 1994) yielding a strain able to

produce 500 mg L1 in fed-batch fermentor culture along

with 600 mg L1 of biotin vitamers. Later advances led to

production by recombinant S. marcescens of 600 mg L1 of

biotin (Masuda et al., 1995).

A process for riboflavin production in Corynebacterium

ammoniagenes (previously Brevibacterium ammoniagenes)

was developed by cloning and overexpressing the organism’s

own riboflavin biosynthesis genes (Koizumi et al., 2000) and

its own promoter sequences. The resulting culture produced

15.3 g L1 riboflavin in 3 days. Genetic engineering of a

Bacillus subtilis strain already containing purine analogresistance mutations led to the improved production of

riboflavin (Perkins & Pero, 1993). An industrial strain of B.

subtilis was produced by inserting multiple copies of the rib

operon at two different sites in the chromosome, making

purine analog-resistance mutations to increase guanosine

triphosphate (GTP; a precursor) production and a riboflavin analog (roseflavin)-resistance mutation in ribC that

deregulated the entire pathway (Perkins et al., 1999).

Vitamin C (ascorbic acid) has traditionally been made in

a five-step predominantlychemical process by first converting glucose to 2-keto-L-gulonic acid (2-KGA) with a yield of

50% and then converting the 2-KGA by acid or base to

ascorbic acid. A novel process for vitamin C synthesis

involved the use of a genetically engineered Erwinia herbicola strain containing a gene from Corynebacterium sp. The

engineered organism converted glucose into 1 g L1 of 2KGA (Anderson et al., 1985; Pramik, 1986). A better process

was devised independently, which converted 40 g L1 glucose into 20 g L1 2-KGA (Grindley et al., 1988). This

process involved cloning and expressing the gene encoding

2,5-diketo-D-gluconate reductase from Corynebacterium sp.

into Erwinia citreus. Another process uses a recombinant

strain of Gluconobacter oxydans containing genes encoding

L-sorbose dehydrogenase and L-sorbosone dehydrogenase

from G. oxydans T-100. The new strain was an improved

producer of 2-KGA (Saito et al., 1997). Further mutation to

suppress the L-idonate pathway and to improve the promoter led to the production of 130 g L1 of 2-KGA from

150 g L1 sorbitol.

Carotenoids were overproduced by introducing carotenoid gene clusters from Erwinia uredovora into E. coli and

overexpressing E. coli deoxyxylulose phosphate synthase, the

key enzyme of the non-mevalonate isoprenoid biosynthetic

pathway (Matthews & Wurtzel, 2000). Lycopene accumulated to 1.3 mg g1 dry cell weight and zeaxanthin to

0.6 mg g1.

196

b-Lactam antibiotics

Cloning has been very important in understanding the

biosynthesis of b-lactam antibiotics (Demain & Elander,

1999), its genetics and improving the production processes.

Early common pathway

All producers of penicillins and cephalosporins, including

cephamycins, use the same two enzymes to start the

biosynthetic process. The steps involve the condensation of

L-a-aminoadipic acid, L-cysteine and L-valine to form the

tripeptide, d-(a-aminoadipyl)-L-cysteinyl-D-valine (ACV)

by ACV synthetase (ACVS), encoded by gene pcbAB (also

known as acvA in A. nidulans). This is followed by cycliza2005 Federation of European Microbiological Societies

Published by Blackwell Publishing Ltd. All rights reserved

c

tion of ACV into isopenicillin N (IPN) by IPN synthase

(cyclase; encoded by pcbB). The cloning of the gene encoding ACVS from P. chrysogenum (Diez et al., 1990), C.

acremonium (Gutierrez et al., 1991) and Nocardia lactamdurans (Castro et al., 1988) contributed greatly to the

elucidation of the biosynthetic pathway. Overexpression of

acvA in A. nidulans, by replacing the normal promoter with

the ethanol dehydrogenase promoter (Kennedy & Turner,

1996), increased penicillin production up to 30-fold. The

cyclase genes from different microorganisms were all cloned

(Aharonowitz et al., 1992; Martin et al., 1997) and provided

pure enzyme for structural studies. Cloning multiple copies

of cyclase into C. acremonium yielded an improved cephalosporin C-producing strain (Skatrud et al., 1987).

The hydrophobic branch

Producers of penicillin use a single step branch involving

penicillin acyltransferase acting on IPN. Its gene penDE (also

known as iat, aat and acyA in A. nidulans) was cloned from

P. chrysogenum into C. acremonium, which led to the

production of penicillin G (in the presence of exogenous

phenylacetic acid) along with cephalosporin C (Gutierrez

et al., 1991). Without cloning, C. acremonium cannot

produce penicillin G.

The hydrophilic branch

All producers of cephalosporins and cephamycins employ a

series of enzymes leading from IPN. First, IPN is epimerized

to penicillin N by IPN epimerase (encoded by cefD). The

next steps include ring expansion of penicillin N by deacetoxycephalosporin C (DAOC) synthase (expandase, encoded by cefE) and hydroxylation by DAOC 3 0 -hydroxylase

(encoded by cefF) to deacetylcephalosporin C (DAC).

Although expandase and hydroxylase are separate enzymes

encoded by separate genes in bacteria, these two activities

are found on the same protein in fungi, which is encoded by

one gene cefEF. At the DAC stage, the overall pathway again

splits into two branches. In C. acremonium, DAC is acetylated to cephalosporin C by DAC acetyltransferase encoded

by cefG. This step is the terminal reaction in cephalosporinproducing fungi. By contrast, actinomycetes carbamoylate

DAC using three enzymes, encoded by cmcH, cmcI and cmcJ

genes to yield cephamycin C (Brewer et al., 1980).

When an industrial production strain of C. acremonium

394-4 was transformed with a plasmid containing the pcbC

and the cefEF gene from an early strain of the C. acremonium

mutant line, a transformant producing 50% more cephalosporin C than the production strain, as well as less penicillin

N, was obtained. Production in pilot plant (150 L) fermentors was further improved by 15% (Skatrud et al., 1989).

One copy of the cefEF had been integrated into chromosome

III, whereas the native gene is on chromosome II.

FEMS Microbiol Rev 30 (2006) 187–214

Downloaded from http://femsre.oxfordjournals.org/ by guest on March 5, 2016

1996), but these problems were mainly overcome. Early

reviews on cloning and expressing antibiotic production

genes in Streptomyces were by Martin and Gil (Martin & Gil,

1984) and Liras (Liras, 1988).

An interesting possibility was the transfer of operons

from one streptomycete to another in the hope that the

structural genes might be better able to express themselves

in another species. Clustering facilitated the transfer of an

entire pathway in a single manipulation. Studies revealed

that many antibiotic biosynthesis genes were arranged in

clusters including undecylprodigiosin, actinorhodin, chloramphenicol, rifamycin, cephamycin, erythromycin, tetracyclines and tylosin among others. Thus, the entire

undecylprodigiosin pathway (‘red’ pathway) of S. coelicolor

was transferred on a 37-kb fragment into Streptomyces

parvulus and the antibiotic was produced (Coco et al.,

1991). Similarly, the entire cephamycin C pathway was

cloned and expressed from a cephamycin-producing strain

of Streptomyces cattleya. When the 29-kb DNA fragment was

cloned into the non-b-lactam producer, S. lividans, one

transformant (out of 30 000) made cephamycin (Chen

et al., 1988). When the fragment was introduced into

another cephamycin producer, Streptomyces lactamgens, a

two- to three-fold improvement was obtained.

In fungi making penicillin G, the three structural genes

(ACVS, cyclase and penicillin acyltransferase) are clustered

on a single chromosome of Penicillium chrysogenum (Smith

et al., 1990) and of Aspergillus nidulans (MacCabe et al.,

1990). In these fungi, the genes of the cluster are separately

transcribed. By contrast, fungal genes coding for cephalosporin biosynthesis are distributed among different chromosomes. The deacetylcephalosporin C acetyltransferase gene

from Cephalosporium acremonium (cefG) is closely linked to

the expandase (cefEF) gene (Gutierrez et al., 1992; Matsuda

et al., 1992) and both are on chromosome II, whereas the

early genes of the pathway (pcbAB, pcbC) are located on

chromosome VI.

J. L. Adrio & A. L. Demain

197

Genetic improvement of processes yielding microbial products

Microbial enzymes

Genes encoding many microbial enzymes have been cloned

and the enzymes expressed at levels hundreds of times

FEMS Microbiol Rev 30 (2006) 187–214

higher than those naturally produced. Recombinant DNA

technology has been used (Falch, 1991): (i) to produce in

industrial organisms enzymes obtained from microbes that

are difficult to grow or handle genetically; (ii) to increase

enzyme productivity by use of multiple gene copies, strong

promoters, and efficient signal sequences; (iii) to produce in

a safe host useful enzymes obtained from a pathogenic or

toxin-producing microorganism; and (iv) to improve the

stability, activity or specificity of an enzyme by protein

engineering. The industrial enzyme business adopted rDNA

methods to increase production levels and to produce

enzymes from industrially-unknown microorganisms in

industrial organisms such as species of Aspergillus and

Trichoderma, as well as Kluyveromyces lactis, S. cerevisiae,

Yarrowia lipolytica and Bacillus licheniformis. Virtually all

laundry detergents contain genetically-engineered enzymes

and much cheese is made with genetically-engineered enzymes. Indeed, over 60% of the enzymes used in the

detergent, food and starch processing industries are recombinant products (Cowan, 1996).

Scientists at Novo Nordisk isolated a very desirable lipase

for use in detergents from a species of Humicola. For production purposes, the gene was cloned into Aspergillus oryzae,

where it produced 1000-fold more enzyme (Carlsen, 1990)

and is now a commercial product. Such lipases are used for

laundry cleaning, interesterification of lipids, and esterification

of glucosides producing glycolipids which have applications as

biodegradable non-ionic surfactants for detergents, skin care

products, contact lens cleaners and as food emulsifiers.

The a-amylase gene from Bacillus amyloliquefaciens was

cloned using multicopy plasmid pUB110 in B. subtilis

(Palva, 1982). Production was 2500-fold that in wild-type

B. subtilis and five-fold that of the B. amyloliquefaciens

donor. An exoglucanase from the cellulolytic Cellulomonas

fimi was overproduced after cloning in E. coli to a level of

over 20% of cell protein (O’Neill et al., 1986). The endo-bglucanase components of the cellulase complexes from

Thermomonospora and Clostridium thermocellum were

cloned in E. coli as was the cellobiohydrolase I gene of

Trichoderma reesei (Shoemaker et al., 1983; Teeri et al.,

1983). Pichia pastoris, a methanol-utilizing yeast, was engineered to produce S. cerevisiae invertase and to excrete it

into the medium at 100 mg L1 (Van Brunt, 1986). Interestingly, in S. cerevisiae, the invertase is periplasmic. Selfcloning of the xylanase gene in S. lividans resulted in sixfold overproduction of the enzyme (Mondou et al., 1986).

Many enzymes are made by filamentous organisms,

which are slow-growing and difficult to handle in fermentors. The transfer of these genes to rapidly-growing unicellular bacteria means that rapid growth and more

reproducible production can be achieved. Other advantages

are more rapid nutrient uptake due to a greater surface/

volume ratio, better oxygen transfer, better mixing and thus

2005 Federation of European Microbiological Societies

Published by Blackwell Publishing Ltd. All rights reserved

c

Downloaded from http://femsre.oxfordjournals.org/ by guest on March 5, 2016

Transformation of P. chrysogenum with the Streptomyces

lipmanii cefD and Streptomyces clavuligerus cefE genes allowed the production of the intermediate DAOC (Cantwell

et al., 1992) at titers of 2.5 g L1. DAOC is a valuable

intermediate in the commercial production of semi-synthetic cephalosporins. Also, cloning of cefE from S. clavuligerus or cefEF and cefG (see next paragraph) from C.

acremonium into P. chrysogenum grown with adipic acid as

side-chain precursor (Crawford et al., 1995) resulted in

formation of adipyl-6-aminopenicillanic acid (adipyl-6APA) and adipyl-7-aminodeoxycephalosporanic acid (adipyl-7-ADCA) in the case of cefE and adipyl-6APA, adipyl7ADCA, adipyl-7-DAC and adipyl-7-aminocephalosporanic

acid (7-ACA) in the case of cefEF and cefG.

Disruption and one-step replacement of the cefEF gene

of an industrial cephalosporin C production strain of A.

chrysogenum yielded strains accumulating up to 20 g L 1 of

penicillin N. Cloning and expression of the cefE gene from S.

clavuligerus into those high-producing strains yielded recombinant strains producing high titers of DAOC (Velasco

et al., 2000). Production levels were nearly equivalent (80%)

to the total b-lactams biosynthesized by the parental strain.

Weak acetyltransferase promoter activity appears to be

the cause of DAC accumulation in broths of C. acremonium.

Cloning of cefG increased its copy number and cefG mRNA,

tripled acetyltransferase activity, and increased cephalosporin C titers in a dose-dependent manner (Matsuda et al.,

1992; Mathison et al., 1993). Cloning of the gene with its

own promoter had no effect on the low level of DAC

acetyltransferase normally observed in C. acremonium (Gutierrez et al., 1997). However, the use of foreign promoters

(the gpd promoter from A. nidulans, the bla promoter from

A. niger or the pbcC promoter from P. chrysogenum) had a

major effect on the level of cefG transcripts, DAC acetyltransferase protein level and activity, and antibiotic production; cephalosporin C production rose by two- to three-fold.

Of the cephalosporins produced, the undesirable DAC

decreased from 80% of the total to 30–39%, whereas

cephalosporin C increased by a similar amount.

Transformation of early strain P. chrysogenum Wis541255 with individual genes, pairs of genes, and all three

genes of the penicillin pathway showed that the major

increases occurred when all three genes were overexpressed

(Theilgaard et al., 2001). The best transformant contained

three extra copies of pcbAB, one extra copy of pcbC and two

extra copies of penDE and produced 299% of control shake

flask production and 276% of control productivity in

continuous culture.

198

Polymers, fuels, foods and beverages

Microbially-produced xanthan gum is not only an acceptable food-thickener but is one of the most promising agents

for enhanced oil recovery in the petroleum industry. Recombinant DNA manipulation of Xanthomonas campestris

increased titers of xanthan by two-fold and increased

pyruvate content by over 45% (Bigelas, 1989; Tseng et al.,

1992). The yield was 0.6 g g1 of sucrose utilized (Letisse

et al., 2001). Ten to twenty thousand tons of xanthan are

produced annually for use in the oil, pharmaceutical,

cosmetic, paper, paint and textile industries (Becker et al.,

1998).

2005 Federation of European Microbiological Societies

Published by Blackwell Publishing Ltd. All rights reserved

c

Escherichia coli was converted into a good ethanol producer (4.3%, v v 1) using recombinant DNA technology

(Ingram et al., 1987). Alcohol dehydrogenase II and pyruvate decarboxylase genes from Zymomonas mobilis were

inserted in E. coli and became the dominant system for NAD

regeneration. Ethanol represented over 95% of the fermentation products in the genetically-engineered strain. By

cloning and expressing the same two genes into Klebsiella

oxytoca, the recombinant was able to convert crystalline

cellulose to ethanol in high yield when fungal cellulase was

added (Doran & Ingram, 1993). The maximum theoretical

yield was 81–86% and titers as high as 47 g L 1 of ethanol

were produced from 100 g L 1 of cellulose.

Cloning of its ace (acetone) operon gene adc (encoding

acetoacetate decarboxylase), ctfA and ctfB (two genes encoding coenzyme A transferase) on a plasmid containing the adc

promoter into Clostridium acetobutylicum resulted in a 95%

increase in production of acetone, a 37% increase in butanol,

a 90% increase in ethanol, a 50% increase in solvent yield

from glucose and a 22-fold lower production of undesirable

acids (Mermelstein et al., 1993). The introduction of the

acetone operon from C. acetobutylicum into E. coli led to

high acetone production by the latter (Bermejo et al., 1998).

Beer wort contains barley b-glucans which reduce the

filtrability of beer and lead to precipitates and haze in the

final product. The gene coding for endoglucanase was

transferred from T. reesei to brewer’s yeast and the engineered yeast strain efficiently hydrolyzed the b-glucans

(Penttilä et al., 1987). Similiar technology created starchutilizing S. cerevisiae strains and wine yeast strains producing lower acidity and enhanced flavor. Brewing yeasts were

modified using recombinant DNA technology so that they

could produce A. niger amyloglucosidase and break down

unfermentable dextrins for light beer production (Van

Brunt, 1986; Hammond, 1988). The glucoamylase gene

from Aspergillus awamori was cloned and expressed stably

in polyploid distiller’s yeast. A high level of glucoamylase

was secreted. Almost all (95%) of the carbohydrates in the

25% starch substrate were utilized and high levels of ethanol

were produced. The engineered strain outperformed S.

diastaticus (Cole et al., 1988).

Brewing yeasts were engineered to produce acetolactate

decarboxylase from Enterobacter aerogenes or A. aceti. This

enzyme eliminated diacetyl and the requirement for the

three- to five-week flavor maturation period which normally

follows a one-week fermentation stage (Sone et al., 1988).

The resulting beer suffered no loss of quality or flavor

(Holzman, 1994).

Bioconversions

Recombinant DNA techniques have been useful in developing new bioconversions and improving old ones. Using a

FEMS Microbiol Rev 30 (2006) 187–214

Downloaded from http://femsre.oxfordjournals.org/ by guest on March 5, 2016

more reliable control of pO2, pCO2 and pH, and a better

organism for mutagenesis.

Aspartase production was increased by 30-fold by cloning

in E. coli (Komatsubara et al., 1986). Captopril esterase of

Pseudomonas putida, used in preparing the chiral captopril

sidechain, was cloned in E. coli with a 38-fold increase in

activity (Elander, 1995). A 1000-fold increase in phytase

production was achieved in A. niger using recombinant

technology (Van Hartinsveldt et al., 1993). Cloning of the

benzylpenicillin acylase gene of E. coli on multicopy (50)

plasmids resulted in a 45-fold increase as compared to

uninduced wild-type production. Interestingly, the cloned

enzyme is constitutive (Mayer et al., 1980). Cloning additional penicillin V amidase genes into wild-type Fusarium

oxysporium increased enzyme titer by 130-fold (Komatsubara et al., 1986).

The properties of many enzymes have been altered by

genetic means. ‘Brute force’ mutagenesis and random

screening of microorganisms over the years led to changes

in pH optimum, thermostability, feedback inhibition, carbon source inhibition, substrate specificity, Vmax, Km and Ki.

This information was later exploited by the more rational

techniques of protein engineering. Single changes in amino

acid sequences have yielded similar types of changes in a

large variety of enzymes. Today, it is no longer necessary to

settle for the natural properties of an enzyme; these can be

altered to suit the needs of the investigator or the process.

For example, a protease from Bacillus stearothermophilus

was increased in heat tolerance from 86 1C to 100 1C, being

made resistant to boiling. The enzyme was developed by

site-directed mutagenesis (Van den Burg et al., 1998). Only

eight amino acids had to be modified. Temperature stability

at 100 1C was increased 340-fold and activity at lower

temperature was not decreased. All eight mutations were

far from the enzyme’s active site. Washing powders have

been improved in activity and low temperature operation by

the application of recombinant DNA technology and sitedirected mutagenesis to proteases and lipases (Falch, 1991;

Wackett, 1997).

J. L. Adrio & A. L. Demain

199

Genetic improvement of processes yielding microbial products

Novel genetic technologies

A new genomic technique called ‘genome-based strain

reconstruction’ allows one to construct a strain superior to

the production strain because it only contains mutations

crucial to hyperproduction, but not other unknown mutations which accumulate by brute-force mutagenesis and

screening (Ohnishi et al., 2002). This approach was used to

improve the lysine production rate of Corynebacterium

glutamicum by comparing high producing strain B-6 developed by Hirao and coworkers (Hirao et al., 1989) (production rate slightly less than 2 g L 1 h 1) and a wild-type

strain. Comparison of 16 genes from strain B-6, encoding

enzymes of the pathway from glucose to lysine, revealed

mutations in five of the genes. Introduction of three of these

mutations into the wild-type created a new strain which

FEMS Microbiol Rev 30 (2006) 187–214

produced 80 g L 1 in 27 h, at a rate of 3 g L 1 h 1, the

highest rate ever reported for a lysine fermentation.

‘Metabolic engineering’ is the directed improvement of

product formation or cellular properties through the modification of specific biochemical reactions or introduction of

new ones using recombinant DNA technology (Stephanopoulos, 1999; Nielsen, 2001). Its essence is the combination

of analytical methods to quantify fluxes and the control of

fluxes with molecular biological techniques to implement

suggested genetic modifications. Flux is the focal point of

metabolic engineering. Different means of analyzing flux

are: (i) kinetic based models; (ii) control theories; (iii) tracer

experiments; (iv) magnetization transfer; (v) metabolite

balancing; (vi) enzyme analysis and (vii) genetic analysis

(Eggeling et al., 1996). Metabolic control analysis revealed

that the overall flux through a metabolic pathway depends

on several steps, not just a single rate-limiting reaction

(Kacser & Acerenza, 1993).

Metabolic engineering has been applied to antibiotic

production (Khetan & Hu, 1999, 1999; Thykaer & Nielsen,

2003). The increases in metabolic flux were carried out by

enhancing enzymatic activity, manipulating regulatory

genes, enhancing antibiotic resistance and heterologous

expression of novel genes. Table 2 summarizes several

examples of progress on the production of those secondary

metabolites.

The production of amino acids shows many examples of

this approach. A useful review of metabolic engineering in

C. glutamicum, especially in relation to L-lysine production,

was published by Sahm and colleagues (Sahm et al., 2000).

Metabolic flux studies of wild-type C. glutamicum and four

improved lysine-producing mutants available from the

ATCC showed that yield increased from 1.2% to 24.9%

relative to the glucose flux. Other recent examples are on

overproduction of aromatic amino acids and derivatives

(Bongaerts et al., 2001), L-lysine (Wittmann & Heinzle,

2002) and glutamate (Kimura, 2003).

There are many other successful applications of metabolic

engineering for products such as 1,3-propanediol (Nakamura & Whited, 2003), carotenoids (Rohlin et al., 2001;

Visser et al., 2003; Wang & Keasling, 2003), organic acids

(Kramer et al., 2003), ethanol (Nissen et al., 2000), vitamins

(Zamboni et al., 2003; Sybesma et al., 2004) and complex

polyketides in bacteria (Pfeifer et al., 2001; Khosla &

Keasling, 2003).

During the last few years, an expanded view of the cell has

been possible due to impressive advances in all the ‘omics’

techniques (genomics, proteomics, metabolomics, etc.) and

high-throughput technologies for measuring different

classes of key intracellular molecules. ‘Systems biology’ has

recently emerged as a term to describe an approach that

considers genome-scale and cell-wide measurements in

elucidating processes and mechanisms (Stephanopoulos

2005 Federation of European Microbiological Societies

Published by Blackwell Publishing Ltd. All rights reserved

c

Downloaded from http://femsre.oxfordjournals.org/ by guest on March 5, 2016

plasmid containing tryptophan synthase plus induction

with 3-indole acrylate, recombinant E. coli was able to

produce 180 g L 1 of L-tryptophan from indole plus

L-serine in 8 h (Yukawa et al., 1988). Whereas S. cerevisiae

normally produces 2 g L 1 of malic acid from fumaric acid,

a recombinant strain containing a cloned fumarase gene was

able to produce 125 g L 1 with a yield of almost 90%

(Neufeld et al., 1991).

An oxidative bioconversion of saturated and unsaturated

linear aliphatic 12–22 carbon substrates to their terminal

dicarboxylic acids was developed by gene disruption and

gene amplification (Picataggio et al., 1992). Product concentrations reached 200 g L 1 and problematic side-reactions such as unsaturation, hydroxylation and chainshortening did not occur.

3-0-Acetyl-4 0 0 -0-isovaleryltylosin (AIV) is useful in veterinary medicine against tylosin-resistant Staphylococcus aureus. It is made by first producing tylosin with Streptomyces

fradiae and then using Streptomyces thermotolerans (producer of carbomycin) to bioconvert tylosin into AIV. A new

direct fermentation organism was constructed by transforming S. fradiae with S. thermotolerans plasmids containing acyl transferase genes (Arisawa et al., 1996).

Recombinant Candida pasteurianum can carry out the

conversion of glycerol to 1,3-propanediol (Luers et al.,

1997). A more economical process involving conversion of

the less expensive glucose to 1,3-propanediol has been

achieved with a recombinant E. coli strain (Nakamura &

Whited, 2003). The project is a collaborative effort by

Genencor International and DuPont (Potera, 1997). The

recombinant strain contains two metabolic pathways, one

for conversion of glucose to glycerol and the other for

conversion of glycerol to 1,3-propanediol (Tong et al.,

1991; Laffend et al., 1996). The 1,3-propanediol (also known

as trimethylene glycol or 3G) is used as the building block to

produce a new biodegradable polyester (3G1).

200

J. L. Adrio & A. L. Demain

et al., 2004). Progress in strain development will depend, not

only on all the technologies mentioned above, but also on

the development of mathematical methods that facilitate the

elucidation of mechanisms and identification of genetic

targets for modification.

A genome-wide transcript expression analysis called

‘massive parallel signature sequencing’ (Brenner et al.,

2000) was used successfully to discover new targets for

further improvement of riboflavin production by the fungus

A. gossypii (Karos et al., 2004). The authors identified 53

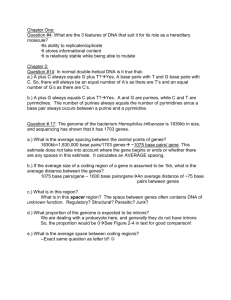

Table 2. Metabolic engineering of antibiotics

Target

1.Manipulation of

structural genes

2. Manipulation of

regulatory genes

Result

Reference

1.1. Amplifying an entire pathway

2.3-fold increase in cephamycin C

1.2. Amplifying a segment of a pathway 7-fold increase in daunorubicin

30% increase in tetracenomycin C

3- to 4-fold increase in spinosyn

1.3. Enhancing resistance

7- fold increase in neomycin

2.1. Amplifying positive regulatory genes

Pathway specific regulators