The Beer Game

advertisement

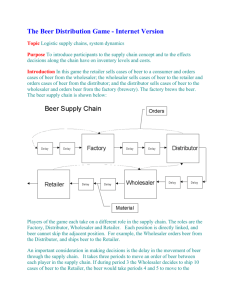

The Beer Game A production-distribution game to understand inventory management 1 Introduction • The beer game is a demonstrator of the behaviour of supply chains • It is based on the main principle of system dynamics: – Structure produces behaviour • The game is employed for educational purposes at most MBA’ s worldwide 2 Overview of the system • There exist four nodes in the game’s supply chain (look at the board): – Retailer (e.g., a supermarket that sells beer to end-customers) – Wholesaler (e.g., a local warehouse that consolidates various items and provides them to local retailers) – Distributor (e.g., a national importer of this particular beer with a centralized warehouse) – Factory, where beer is brewed and packaged 3 Overview of the nodes • Each position: – Is identical, in terms of the rules of the game, except for the factory – Has an initial inventory of beer – Receives orders from and ships beer to the downstream node of the chain – Orders beer from the upstream node – One or two players are associated with it 4 Overview of delays (lead times) • Beer is received after a shipping delay of two time units (e.g., 2 weeks or days) • In case of the factory, beer is received after a production delay (it takes 2 time units to manufacture any beer batch) • Orders are received after a mailing delay (it takes 2 time units from the moment you place an order to the moment this is processed by the upstream node) 5 Objective of the game • The goal is to minimize the total cost • Costs are computed as follows: – Inventory carrying costs (costs of holding inventory for one time unit) are €0.50 per case of beer per week (time unit = 1 week) – Out-of-stock costs (or backlog costs, i.e., no onhand inventory to satisfy orders) are €1.00 per case of beer per week – Sum of carrying and backlog costs is total cost 6 Rules of the game • No communication between positions is allowed, e.g., retailers should not talk to anyone else – same for wholesalers, distributors and factory • Only communication is through the passing of orders and the receiving of beer • Retailers are the only ones knowing actual customer orders – they should not reveal this information to anyone else 7 Initialization of the board • Each chip on the board represents a case of beer (one unit of inventory) • There exist twelve (12) chips representing twelve cases of beer in each inventory position (warehouse of each node) • There exist four (4) chips in each shipping delay and production delay box • There exist order slips in each order box (orders placed, incoming orders, production requests) face down 8 Additional information • The raw materials inventory at the factory and the production capacity is infinite (i.e., the factory can produce any batch size) • The capacity of the shipping trucks (moving inventory between nodes) is infinite • The flow of materials (cases of beer) is from factory to retailer, while the flow of information (orders) is reverse (from the retailer to the factory) 9 Steps of the game • Step 1: – Receive inventory and advance shipping delays – Factory advance the production delay • Step 2: – Look at incoming orders and fill them • Retailer looks at customer order cards • Factory looks at incoming orders, not production requests 10 Steps of the game • Step 2 (continued): – All incoming orders plus orders in backlog must be filled – If inventory is insufficient to fill incoming orders plus backlog, fill as many orders as you can (push all your inventory forward) and place unfilled ones to backlog Orders to Fill = New Orders + Backlog this week this week last week 11 Steps of the game • Step 3: – Record inventory or backlog • Step 4: – Advance order slips – Factory brews, i.e., it converts the production request (from last week) into cases of beer and puts the cases (chips) in the first production delay 12 Steps of the game • Step 5: – Place and record your orders (retailer, wholesaler, distributor) – Factory places and records its production request – This is the only decision you have to make! • Synchronize your steps (select a team leader and follow his “commands”) 13 Documentation • Write down: – Level of inventory (count of chips in your warehouse) – Backlog (count of chips in unfilled orders) – Orders placed at the Record Sheet provided at each position • Best of luck! 14