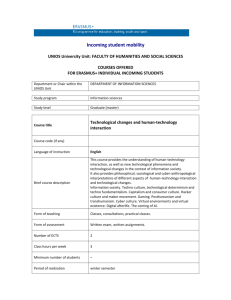

Business organisational response to environmental challenges

advertisement