Design for tolerance of electro

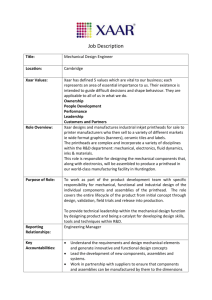

advertisement