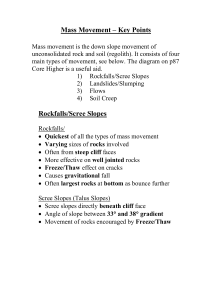

prescriptive measures for man-made slopes and retaining walls

advertisement