MODULE 2

advertisement

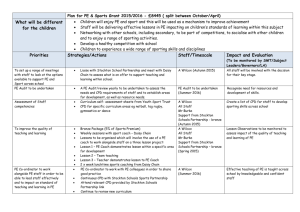

2 Getting Started/Lab Programming MODULE 2 LAB PROGRAMMING October 2013 2 Getting Started/Lab Programming 1. Getting Started 2. Scoping the Project 3. Lab Programming • What is programming? • Information gathering • Organizing and presenting data P2 2 Getting Started/Lab Programming Getting Started •Project Manager -- Owner representative -- Responsible for budget and schedule -- Conduit to the organization -- Single point of communication •Key User Representative for entire project or at least for each user group / department •Identify key users to inform design team on their requirements P3 2 Getting Started/Lab Programming Who? Develop The List Of Key Stakeholders: •Owner •Lab supply personnel •Academic Faculty •Building Facility personnel •Senior Researchers (PI’s) •IT managers / IT maintenance •Lab Managers •Security Department •Graduate Students •Building Maintenance personnel •Occupational Health and Safety departments P4 2 Getting Started/Lab Programming Develop A Series Of Committees For Feedback And Decision Making STEERING COMMITTEE GRAND USER COMMITTEE •Building Committee •“Grand” User Committee SPECIFIC 1 SPECIFIC 2 •Specific User Committees COMMITTEES •One key decision maker and one conduit for information flow STEERING COMMITTEE •One clear line of communication flow •One key authority chain for committee decisions. Are they advisory or do they make decisions? •What happens when flow is subverted? SPECIFIC 3 USERS PROJECT MANAGER CONSULTANT INFORMATION FLOW P5 2 Getting Started/Lab Programming •Consultant Team -- Programmer -- Architect and Engineers -- Experienced firms and people (not learning on your project) P6 2 Getting Started/Lab Programming •Consider construction procurement model -- eg. Design, Bid, Build Construction Management Construction Management at Risk Design Build -- Affects design process -- Affects schedule -- Can assist with buildability issues & costing -- Can affect quality of end product P7 2 Getting Started/Lab Programming •Scheduling Workshop -- With the entire team Owner, Consultants and Builder -- Establish completion date -- Together build milestones, deliverables and action dates -- Team building P8 2 Getting Started/Lab Programming Scoping the Project Understand Key Drivers •Research grant •Private donor •Large pharmaceutical •Venture capital •Company expansion •Special funding programs •Government funding P9 2 Getting Started/Lab Programming Understand The Rules Of The Game •If a research grant there are significant reporting – area rules; room naming conventions •Organization’s policies? •Landlord requirements? •What about other requirements – LEED; University processes; site masterplanning SFU SERVICE SPACE FUTURE CREM ENTRY FOYER LEVEL 6000 CREM MAIN ENTRY CFI Area CREM Diagram P10 2 Getting Started/Lab Programming Establish Key Goals with Project Manager / Client Group •Meeting with key stakeholders •Whose agenda is the loudest? •Are there un-stated elements? •Phasing? •Sustainability? P11 2 Getting Started/Lab Programming Work With The Budget •BMW or Chevy? •Does funding come with a time line? ? P12 2 Getting Started/Lab Programming Lab Programming Program of Requirements P R ELIMINA R Y SP A C E LIST Kwantlen Polytechnic University Langley, BC PRELIMINARY SPACE LIST PROPOSED AREA S.M. EXISTING AREA S.M. Existing Room What A Program Is Not: LABS: All labs should incorporate the following: • Maximize storage • Adequate lighting is important • Safe traffic flow patterns are critical • Labs design should incorporate sustainable features •Only just numbers or areas •Plan or drawing of space Room: 1325 Biology/Horticulture/Sustainability Science • Fixed benches with electrical outlets and one sink per bench • Fumehood • Will be used as a teaching space for theory and technique • Space for large equipment such as salt water tanks, fridges, etc • Access to prep space and to the bunker storage site 187 187 Room: 1345 Chemistry/Horticulture 106 (existing) 106 • • • • • • Room: 1365 Benches with gas, air, power and water Fumehoods Distilled water Access to prep space and to the bunker storage site Access to balance room Access to analytical equipment room Environmental Protection Lab/Soil Chemistry • Benches with gas and air; one side of bench to have a sink running along entire length with 5 compartments and the opposite side of the bench to have a one compartment sink CHERNOFF THOMPSON ARCHITECTS Project 29032 137 98 February 10, 2010 Space List P13 2 Getting Started/Lab Programming What A Program Is: •Defines the problem, doesn’t solve it •An understanding of the needs University of Washington Ecogenomics Lab P14 2 Getting Started/Lab Programming Levels of Programming •Strategic The University of Victoria A-3 ACU – CAGEWASH SCIENCE BUILDING Page 4 4 COMPONENT PLANNING CRITERIA Functional Relationship Diagram •Master •Functional •General Space Planning •Detailed Space Planning •Room by Room Data specific information Space Requirements Ref 01 Space Units nsm/unit nsm Remarks Dirty Cage Wash 1 62 62 Cage washer 02 Clean Cage Wash 1 50 50 Autoclave 03 Clean Staging/Storage 1 23 23 Filling stations 04 05 Total Chernoff Thompson Architects 135 15/04/05 Project # 24040.1 P15 2 Getting Started/Lab Programming Information In Program LABORATORY Wet Chemistry •Clear and usable by architects and engineers •Practical FUNCTIONAL RELATIONSHIPS from other areas to avoid cross contamination -Leach area; could be near Digestion and not in wash-up as is currently -Cyanide room; a separate room to avoid cross-contamination -need transferring stations independent from digestion hoods for increased safety and productivity KEY ISSUES -repetitive nature of weighing task requires ergonomic study -weigh room is dusty; currently Hepa Vacuums at each station for use by staff -prefer the sample box storage in one area in the room for easy access and alphabetizing -the sample box storage area includes 2 days active storage -sunlight on balances can affect readings -green screens of weighing computers need careful lighting coordination -a separate wash-up room required -storage for racks and Teflon tubes -Norm station has radioactive material under plastic cover -transferring from flasks done under canopy-style fume hoods; further study on this process needed -Digestion is a very corrosive environment -fume hoods are all perchloric-style -samples are stored under canopy-style fume hood; need to study if this is best storage method -Hot Blocks are located in fume hoods and require significant power -independent acid bottle changing station -bigger bubbler station to hold 3 sample carts •Not too long Can include: •Appendices AREAS •Room data sheets •Equipment cut sheets Spaces Weighing: Standards storage room Weigh stations (30@6’X8’) Equipment storage Small PC stations (4 3 @40ft²) Special samples desk Norm station Net Area Characteristics (ft²) 32 1440 80 160 40 120 PPE Storage Supervisor workstation Weighing manager workstation Subtotal Weighing 64 64 2000 122 1031 80 110 40 20 -16’ long shelves secured storage room -need new ergonomic design, need central vacuum (flat screen?) -incl. storage area for supplies and gloves -sits on 2 desks (small area) 10’ x 4’; weighing bench Equip = 7’ x 2’, sits on work bench 133 below work benches 40 -to be near weighing area 45 1488 Net to Gross ratio = 1.1% (walls, corridors, etc. within the department) Weighing Gross Area = 2200ft² 1621 tual = 2315ft² x 1.1% = 1783 Ac- Sample Program Page 1 P16 2 Getting Started/Lab Programming Process of Programming: LABORATORY Wet Chemistry AREAS 1. 2. 3. 4. 5. Definition of scope before design Gathering data Synthesizing data Understand wants vs. needs Produce a final reference document Spaces Digestion: Cyanide room Main digestion lab: Hoods (19 x 54ft² x 1.3) Canopy (34’ x 9’ x 1.3) Bench Space (19 x 36ft² x 1.3) Bubbling Area (12’ x 8’ x 1.3) Wash up area Sample Holding Solutions (12 x 15 x 1.3) Feeder Room Area (12 x 15 x 1.3) Manager workstation Supervisor workstation office PPE Storage Leach Area +MS 81 Area @ 135ft² require 2 Canopies on top of 2 Furnaces Subtotal Digestion: Net Area (ft²) 174 3500 64 64 80 200 ______ Net Area (ft²) Characteristics 255 3190 -(current = 174ft²) -(includes geo, assay, fusion) current = 2011ft² *SEE NOTE BELOW 1000 260 640 140 188 410 1350 400 (398) 890 (889) 125 Adj to Transfer Canopies and Dumping 200 Adj to Weighing; Including Dumping 250 (234) 250 100 120 70 135 ______ 4120 (234) Shelving Area for weighed samples and clean flasks Adj to Weighing and Wash Up Area -just outside main lab with window into main lab “” Net to Gross ratio = 1.1% (walls, corridors, etc. within the departme nt) Digestion Gross Area = 4532 ft² (Current area = 5131ft²: Weighing = 2767ft², Digestion = 2364ft²) Department Gross Area = 646 ft² HOODS (6’x9’) 14 X 6’ perchloric 2 X 6’ Aqua Regia ME 3 X 6’ Aqua Regia AU = 19 X 6’ hoods 19 X 54 ft² = 1026 ft² OTHER 1 X 12’ canopy (digestion 2’ depth) 6 X 4’ fusion furnace canopy 2 X 6’ canopy (transfer 4’ depth) 1 X 12’ canopy (transfer 4’ depth) 34’ X 9’ = 306 ft² *include for 30, 6’ fume hoods within 5 year horizon. First Year: 12 perchloric-type for test tube digestion; 6 fume hoods with 2 hot plates each; 1, 12’ long transferring canopy; 2 Aqua Regia Hoods. -adjoining bench space near fume hoods -allow for bench space equal to fume hood length; consider different arrangements at hoods and lab bench space for more efficient / safe work area -allow for transfer area at digestion entry (200ft²) Sample Program Page 2 P17 2 Getting Started/Lab Programming Information Gathering Gathering Data -For Each Department / Group •What do they do? •Staffing and hours of work •Key issues •Major space characteristics •Rooms or spaces needed and ideal dimensions •Key adjacencies •List of major equipment •Future plans SFU TASC II Bennet Lab P18 2 Getting Started/Lab Programming Visit Sites – Project & Other Examples •Tour with knowledgable users •Identify issues, priorities •Limitations / opportunities -- How much space -- New vs. Reno -- Context -- More than one possible site? -- Difficult to route new drains? -- HVAC supply capacity -- Power limits -- Routing for duct shafts? -- Access to natural light Initial Site Visit SFU Podium 2 Site Visit Environment Canada Lab P19 2 Getting Started/Lab Programming Where / How To Gather Information: Space Criteria – References? Standards Rules Of Thumb •Biosafety Levels; •Area per P.I. •Lab bench area / lineal distance per •Transgenic Requirements worker •Funding Agency •% support / prep. vs. Lineal lab bench •CSA/NIH Guidelines •Clean Room Levels •Other? What Do They Have For Space Now? •Area summaries •Lists •Photos •Area per equipment? P20 2 Getting Started/Lab Programming Metrics - “Rule of Thumb:” The National Institutes of Health Standards / Principal Investigator m² ft² 16.5 8.25 2.79 0.84 2.88 31.26 177.5 89 30 9 31 336.5 Ancillary Office Admin Laboratory work space Laboratory support space Research staff space Ancillary Lab admin Optimal Area Work Support P21 2 Getting Started/Lab Programming Process: Set Up A Series Of Meetings Pre- Meeting 1 Questionnaire: 1.Who are you? 2.What do you do? 3.How do you fit in your organization? 4.What will you do differently in the future? 5.What works well now? 6.What doesn’t work? 7.What are your key concerns? Meeting 1.0 – Review the above Meeting 1.5 – Review existing situation on site – note areas of concern (boxes piled up, smells, spills, cleanliness issues, crowding, deteriorating finishes) P22 2 Getting Started/Lab Programming Process Meeting 2 – Detailed Information: •Wet lab; dry lab; office space •Structural concerns – weight, hanging •Large scale equipment (over 6’0” in any direction?) •Fume hoods •Radioisotopes •Perchloric hoods •Create radiation / shielded for radiation •Lab waste •Acid neutralization •Biohazards / chemical / radioactive – type and quantities •Neutralization •Air requirements •Glass – washing •Chilled process water •Clean room •Cooled server room •Emergency power •Specialized lighting •Controlled lighting •Specialized power (not 120/20A) •Heat rejecting equipment •Piped lab gases •Pure water-quality P23 2 Getting Started/Lab Programming Meeting Follow Ups With Users For Special Topics Meet With: •Occupational Health and Safety departments •Lab supply personnel •Building Facility personnel •IT managers / IT maintenance •Security Department •Sustainability Key Stakeholders •Building Maintenance personnel •Others ... P24 2 Getting Started/Lab Programming Shared Services •Look for Duplicate Functions -- Dishwashing -- Sterilizing -- Storage -- Chemical storage -- Gas storage -- Meeting -- Library -- Special Equipment •Find a Champion UVic Chemical Storage •Consider Shared Areas with Fences P25 2 Getting Started/Lab Programming •Servicing Areas - Program These Too! -- Service -- Delivery/receiving -- Staging -- Recyling -- General storage -- Security -- IT -- Facility equipment -- Maintenance personnel space -- Staff lockers P26 2 Getting Started/Lab Programming Analyzing the Data •Prepare space list with areas •Identify key space determinants •Produce space relationship diagrams •Space fit studies Space List Space Fit Example Work Flow Diagram P27 2 Getting Started/Lab Programming Organizing & Presenting the Data •Needs to be clear and usable by Architects and Engineers •Readable by Owners and scientists •Practical •Not too long •Simple diagrams Relationship Diagram P28 2 Getting Started/Lab Programming Organizing & Presenting the Data •Deliverable -- Report book -- Verbal description of users and their functional needs -- Description of groups -- Identify numbers of people now & projected, plus roles -- Address future growth and change anticipated -- Security -- Final space list with areas Program Example P29 2 Getting Started/Lab Programming Can Include Detailed Appendices With: •Room data sheets •Equipment cut sheets •Chemical lists •Test fit layouts •Adjacency Diagrams Equipment Cut Sheet P30 2 Getting Started/Lab Programming Equipment Lists: UNIVERSITY OF WASHINGTON EQUIPMENT BENJAMIN HALL BUILDING, STRAND LAB EQUIPMENT COORDINATION LOG PROJECT #29038 •Useful for design, purchasing, moving, contractor responsibilities 1 2 3 4 •Supplemented by cut sheets / product data •Keep track of the updated versions 5 6 7 8 9 10 11 12 13 14 15 16 17 18 Tender Required? Equipment No. •Continues through entire project Equipment Description Quantity •Working document Line No. •Start it at programming Location of Equipment (Room) $+) Wilcox 169 - Wilcox 169 Wilcox 169 % & Wilcox 169 Wilcox 169 ! Wilcox 169 - Wilcox 169 * Wilcox 169 + Wilcox 169 Wilcox 169 Wilcox 169 Wilcox 169 Wilcox 169 %& Wilcox 169 Wilcox 169 Wilcox 169 % & Wilcox 169 Wilcox 169 P31 2 Getting Started/Lab Programming UNIVERSITY OF WASHINGTON EQUIPMENT BENJAMIN HALL BUILDING, STRAND LAB Department: Updated: EQUIPMENT COORDINATION LOG PROJECT #29038 Completed by (name): Equipment Specifications 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 29 30 31 32 33 34 35 4/14/201 37 - Wilcox 169 ,- +.#. ++ M 15 110 Wilcox 169 ,- +*#. +,#. Y 8.4 110 + Wilcox 169 ,1 ++#. +- Y 8.4 110 Wilcox 169 ,/ *, */#. Y 1.28 Wilcox 169 / *, *2 Y 1.8 110 Wilcox 169 *+#. ++ *. Y 13.75 110 1.5 110 Wilcox 169 +1#. *1 +- Y %& Wilcox 169 *- +- +0#. Y 15 110 Wilcox 169 ++ ++ ,, M 14 110 Wilcox 169 *, *-#. *2 Y 2 110 % & Wilcox 169 ** 1#. **#. Y 0.87 110 Wilcox 169 *0 *)#+. *+#. Y Wilcox 169 *+ ++ +.#. Y Wilcox 169 *1 *,#. ++#. Y 15 Wilcox 169 **#. *) **#. Y 0.8 110 Wilcox 169 -- +) ++ N 20 220 !* Wilcox 169 2 *) ++ Y 8 110 !+ Wilcox 169 *. +* Y 5.2 110 Wilcox 169 - *, *) Y 0.25 110 Wilcox 169 -#. *+ *+#. Y 5 110 Wilcox 169 *. .#. 1 Y 8 110 * Wilcox 169 , 0#. 2 Y 0.08 110 + Wilcox 169 1#. *) **#. Y 0.25 110 * Wilcox 169 - 1#. ** Y 10 110 More 201 +* *, *2 Y 10 110 More 201 *+ */ *1 Y 10 Glass bead sterilizer Wilcox 169 8 5 5.5 Y 0.82 Water purifier Wilcox 169 18.1 21.7 10.6 N .7? Wilcox 169 77 18 48 N 5 4 computers Date Date Vendor Name Drain Non Potable DI Water Potable Water Outlet Height Heat to Room BAS Diversity Factor Institute Lan DI Required Delivery Date Comments x Transilluminator, computer, printer should be close Access to compressed He, Ar tanks, computer 110 %*1& 3 lights Anticipated Delivery Time 110 Plate rack MECHANICAL 110 * 44 UPS 110 +/ Condensate 11 +/#0. Drain M Wilcox 169 LOAD (KVA) Exhaust +/ ! Steam 220 Comp.Air 110 10 City Water 7.5 N 01 depends Gas M Wilcox 169 LVP -+ ,+ Wilcox 169 HVP ,+ ,- % & Cycle 110 7.5 Phase 110 5 N Weight (lb) 5 N .) New? N ,+ ,1 Existing? ,+ +1#. 0/ Used? +1#. 0) Wilcox 169 Supplier 2 0) Wilcox 169 Supplier 1 Wilcox 169 - Contractor $+) Nitrogen Outlet Type Emergency Power Amps/Watts Alarm Signal Bench Top (Y-yes, Nno, M-maybe) Tender Required? Width (in.) 3 Location of Equipment (Room) Utility Requirements Electrical Load Requirements (refer to attached Electrical Equipment List) Depth (in.) 2 Size Requirements Height (in.) 1 Quantity Equipment Description Equipment No. Line No. Equipment Provided by: 5 110 110 110 110 x x Y Equipment List P32 2 Getting Started/Lab Programming Hazardous Materials List: HAZARDOUS MATERIALS Lab PI •Start it at programming •Important for Code Analysis •Keep track of the versions Name Room No. #### Material Manufacturer H Glycerin Antifreeze Biodiesel Diesel acetic acid, glacial Hydrogen acetone potassium hydroxide sodium hydroxide methylene chloride chloroform Methane trifluoroacetic acid potassium hydroxide 0.01N, in isopropanol Potassium Cyanide Potassium Hydroxide potassium chloride reference solution conductivity standard nitric acid sulfuric acid toluene hexanes N N Aldrich Sigma 2‐propanol acetone, >= 99.5% benzene acetonitril N‐Propl Bromide, Aliphatic Alcohol, and Vishay CSM‐2 Degreaser Butylene Oxide (I,2 Epoxybutane) 98% 2‐Propanol and 2.0% n‐ Vishay M‐Bond 200 Catalyst‐C Phenyldiethanolamine Methyl 2‐Cyanoacrylate, Ploy Methyl Vishay M‐Bond 200 Adhesive Methacrylate, and Hydroquinone P33 Ethanol, 2‐Butanol, Rosin, 2‐Propanol, N 2 Getting Started/Lab Programming PROJECT NAME HAZARDOUS MATERIALS Lab PI Name Room No. #### Material Manufacturer Glycerin Antifreeze Biodiesel Hazard Class Solid Pounds Gas Boiling Point Flash Point Carcino‐ OSHA Monthly Flamm. State genic Hazards Usage Cabinet (L, S, G) 55 350F 260F 321F Diesel C II 55 >125F combustible acetic acid, glacial C II 1.06 103F combustible Hydrogen acetone potassium hydroxide sodium hydroxide methylene chloride Flammable gas F IB Cor Cor F IC 1.06 500g 1Kg 1.06 chloroform Non‐Flammable Non Flammable 0.53 0 53 Methane trifluoroacetic acid potassium hydroxide 0.01N, in isopropanol Potassium Cyanide Flammable gas Cor 0.03 Potassium Hydroxide potassium chloride reference solution conductivity standard nitric acid sulfuric acid toluene hexanes 2‐propanol acetone, >= 99.5% benzene acetonitril N‐Propl Bromide, Aliphatic Alcohol, and Butylene Oxide (I,2 Epoxybutane) 98% 2‐Propanol and 2.0% n‐ Phenyldiethanolamine Methyl 2‐Cyanoacrylate, Ploy Methyl Methacrylate, and Hydroquinone Ethanol, 2‐Butanol, Rosin, 2‐Propanol, Methanol, and Dimethylammonium Chloride Tin, Lead, Antimony, and Rosin Isopropyl Alcohol, and Toluene Xylene, Ethyl Benzene, and Oil Modified Polyurethane Methylene Chloride, Chlorobromomethane, and rosin soap Aromatic Hydrocarons, Xylenes (O‐, M‐, P‐ Isomers), and Isobutane / Propane Mixture Vinlyl Ester Corrosion Resin Vi l l E t C i R i NOROX Mekp‐9H Loctite Brand Hysol Epoxy Ethanol Perchloric Acid Picric Acid Hexane Xylene Isopropyl Alchol Sodium dodecyl sulfate N,N,N',N'‐Tetramethylethylenediamine (TEMED) C IIIB C IIIB C IIIB Liquid Gallons Aldrich Non‐Flammable Poison Sigma NF Vishay CSM‐2 Degreaser Vishay M‐Bond 200 Catalyst‐C Vishay M‐Bond 200 Adhesive Vishay M‐Fulux AR (soldering flux) Vishay Solder Vishay M‐Line Rosin Solvent Vishay M Coat A Air Drying Polyurethane Stress Coat ST‐70F/21C Brittle Coating Tracer Tech Penetrant 300A Spray Resin S R i Resin Catalyst Hysol Resin w/ catalyst 0.09 extrememly flammable in presence of open flames, sparks and static discharge & oxidizing materials Very hazardous in case of skin contact (corrosive, irritant), of eye contact (irritant, corrosive), of ingestion, of inhalation. N/A Corrosive Corrosive flammable flammable Heat, flame, strong oxidizers, acetaldehyde, acids, chlorine, ethylene oxide, hydrogen‐palladium combination, hydrogen peroxide‐sulfuric acid combination, potassium tert‐butoxide, hypochlorous acid, isocyanates, nitroform, phosgene, aluminum, oleum and perchloric acid. 54F 0.03 0.03 1 0.03 0.03 NFP 0.25 F IB Strong caustics and chemically active metals such as aluminum, magnesium powder, sodium, or potassium; acetone, fluorine potassium; acetone fluorine 0.03 C IIIB Flammabl Aerosol F1C C3A F1A F 1B F0, H3, R3, Contact 4 Class 1.1D Explosive H3, F3, R1, Contact 2 F3.3, H2, FIC F 1B C IIIB G extrememly flammable in presence of open flames, sparks and static discharge & oxidizing materials Highly reactive with acids. Reactive with organic materials, metals, moisture. 500 gm NFP Incompatablility hydrogen peroxide, bromide, and chromic acid strong oxidizing agents, such as chlorates,nitrates, peroxides, Corrosive 25 gm 1.06 1.06 1.06 1.06 F 1B NFP F 1B L 0.26 F IA F IB F IB F IB F IB C IIIA G flammable Corrosive Corrosive flammable health hazard 200 0.26 0.66 0.13 1.06 1.06 L L L L 300 Non‐Flammable Cor Cor F IB F IB F 1B Y Y 0.09 10 1 1 8 0.13 0.26 0.26 1.32 0.26 explosive flammable flammble 4 Gallons 20 ml 50 ml 50 ml 200 ml 250 ml 25 g 25 g Hazardous Materials List1 P34 2 Getting Started/Lab Programming Room Data Sheets: •List items needed to be covered – including mech and elect. •What does mech. and elec. need from a program? P35 2 Getting Started/Lab Programming Architectural / Mechanical Data Electrical / Communications Data P36