Safety and Health Program Manual

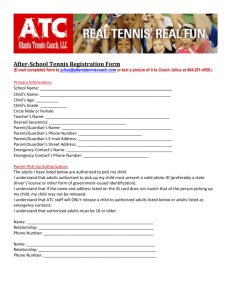

advertisement