SAFETY and HEALTH MANAGEMENT STANDARDS

advertisement

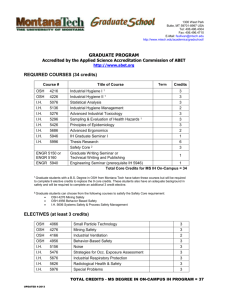

SAFETY and HEALTH MANAGEMENT STANDARDS The Verve Energy Occupational Safety and Health Management Standards have been designed to: Meet the Recognised Industry Practices & Standards and AS/NZS 4801 Table of Contents Introduction ...............................................................................................3 OSH Standard 1. Leadership and Accountability.......................................................4 Appendix 1 – Safety and Health Responsibility and Authority table .........................5 OSH Standard 2. Safety and Health Planning............................................................6 OSH Standard 3. Statutory and Other Obligations Management ..............................7 OSH Standard 4. Risk Management..........................................................................8 OSH Standard 5. People Training and Behaviour ......................................................9 OSH Standard 6. Safety and Health Communication and Consultation ................... 10 OSH Standard 7. Safe Systems of Work .................................................................. 11 OSH Standard 8. Working with Contractors, Suppliers and Partners ...................... 12 OSH Standard 9. Occupational Health Management .............................................. 13 OSH Standard 10. Learning from Incidents ............................................................. 14 OSH Standard 11. Emergency Management ........................................................... 15 OSH Standard 12. Audit and Review....................................................................... 16 Safety and Health Management System................................................................. 17 2 Introduction The Verve Energy Occupational Safety and Health (OSH) Management Standards define and establish structured systems of work to effectively manage OSH aspects of Verve Energy operations. The Standards meet the recognised industry practices and standards as well as align with AS/NZS 4801. The AS/NZS 4801 Management system model involves five key principles driving continual improvement. Continual Improvement Policy Management Review Planning Checking and Corrective Action Implementation and Operation The 12 OSH standards: • define critical elements and requirements for the foundation of the OSH Management System; • describe the Verve Energy Safe System of Work applied to deliver a high standard of OSH performance; • guide and support the Management Team toward meeting OSH policy objectives and legislative requirements; and • will drive a continuous improvement process. The Verve Energy OSH Management Standards document is the overarching OSH document and must be communicated to all employees. No employee or contractor can start work without having access to the Verve Energy systems of work. These Verve Energy OSH Management Standards will be supported through development of sub elements within the OSH system that include but are not limited to plans, procedures, checklists and forms. This document is not intended to replace or alter any legal requirement or Australian Standard and is intended this document shall be used in addition to such requirements and standards. Disregard for standards or safe work procedures by employees or contractors may result in disciplinary action. The Verve Energy OSH Management Standards include the OSH Management System Structure as depicted on page 17. The Verve Energy OSH Management Standards will be reviewed, updated and approved using the Standards Approval Form. 3 OSH Standard 1 Leadership and Accountability Verve Energy’s commitment for a proactive position on leadership and accountability: • Ensures employees at all levels at Verve Energy are accountable and responsible for their own safety, the safety of their work colleagues and protection of the environment in which they operate. Managers and Supervisors shall be held accountable for accomplishing this by: • Leading by example, exhibiting exemplary leadership practice and demonstrating appropriate OSH behaviours. • Developing and establishing OSH objectives and targets and developing the methods and plans to achieve their goals. • Promoting OSH awareness and safe behaviours, and ensuring the operating standards and Safety & Health Policy are communicated to all employees and contractors. • Measuring, reviewing and continuously improving OSH performance. • Establishing and resourcing the organisation appropriate for the level of risk. • Defining and communicating roles and responsibilities. • Acting immediately to correct non‐conforming behaviours and physical conditions. • Establishing workplace mentors to drive learning outcomes that result in practical ‘on the job’ applications. • Taking appropriate disciplinary action where employees or service providers deliberately fail to adhere to Verve Energy’s Behaviour and Work Standards. Key Deliverables To implement these Standards: • Senior Management must establish, communicate, implement and periodically review the OSH policy and the OSH Management System, and must set challenging objectives and develop plans to achieve them. • Senior Management must identify and provide sufficient resources to manage OSH risks and opportunities. • Senior Management must identify, document and communicate OSH responsibilities and accountabilities for employee and contractor roles. • All employees and contractors must demonstrate visible leadership, be responsible for effective management, and consistently deliver on their accountabilities. • Employees must be actively involved in the development and implementation of the OSH systems including all high risk activities. • The continuous improvement process must be utilised to develop and enhance OSH practices. • Lead by example; “The standard you get is the standard you walk past”. • Ensure employees and contractors are competent to perform assigned tasks. • Question people about their knowledge of procedures and processes. • Senior Management must recognise, reinforce and reward OSH initiatives, desired behaviours and outcomes. • Create opportunities to reinforce values, initiatives, requirements and successes. Appendix 1 ‐ Safety and Health Responsibility and Authority Table 4 OSH Standard 1 – V1 ISSUED 28/3/11 OSH Standard 1 Leadership and Accountability Appendix 1 ‐ Safety and Health Responsibility and Authority Table Principle: Management is accountable but everyone is responsible for OSH. Intent: To ensure that the responsibility and authority with respect to OSH is defined, documented and understood by all Verve Energy employees. MD OSH Dept GM’S Site Mngt Site OSH Supply Spvrs Employees A A A A A A A S S, P A S S S D, I D, I D D, I, G D, I, G D, I, G D, I D, I, G D, I, G D, I, G D, I D, G, S D, I, G S S I S S S S S, P S, P S S S, I S, P S I I I, F I, F I, F S S, P S, P S, F S, F S, I S, P F I I I, F I, F I, F S S, P S, P S, F S, F S, I S, P F I I I, F I, F I, F S S, F S, F S, F S, F I S, P F I I I, F I, F I, F S S, P S, P S, F S, F I S, P F F F F F F F F F F F F S G S D G, I I F I F I, P I I, P I, P I I I I I I I I I F F F F F F F F F F F F F P I, P I, P D, I, P D, I, P S, I, P I, P S, I, P D, I S, I, P S, I, P I, P I, P D, I, P I, P P P F P P P P P F P P P P I, F P Corporate Responsibility OSH Organisational Structure OSH Policies and Objectives OSH Roles and Responsibilities OSH Management Standards OSH Golden Rules OSH Safety Management Plan OSH Budget OSH Schedules Critical Risk Control Planning OSH Information Systems OSH Intranet Report on OSH Performance Management Reviews Site Infrastructure Responsibility Position Descriptions Maintain Site OSH Regulatory Requirements Workplace Inspections Essential Service Management Project OSH Management Communication and Consultation Media Traffic Management Site Security Ergonomic Office Layout Hazardous Substance Management Contractor Management and Selection Hygiene Management Injury Management Data Trend Analysis Emergency Systems S D, G, S, I S D D, G, I S S S S S S S S S S S S S D, G D, G, S, I D, G D, G, S, I D, G, S, I D, G, S, I D, G, S, I D, G, S, I D, G, S, I D, G, S, I D, G, S, I D, G, S, I D, G, S, I S, G S S, G S S S S S S S S S S S, I, G D S, G D D D D D D D D D D G, P D, G, I G D, G, I D, G, I D, G, I D, G, I D, G, I D, G, I D, G, I D, G, I D, G, I D, G, I Management and Supervision OSH Continuous Improvement Hazard Identification and Risk Assessment Plant and Equipment Compliance OSH Training Plan Training Development and Assessment OSH Competency Assessment OSH Observations OSH Committee or Alternative Forum Safe Work Procedures Fit for Work Health Surveillance OSH Incident Reporting Incident Investigation Corrective Actions OSH audits S S S S S S S S S S S S S S S P D, G D, G G, S D, G, S, P D, G, S, P D, G, S, P D, G, S, P D, S, G D, S, G D, S, G D, S, G D, G G, S D, G, P P S S S S S S, P S, G S S S S S, G, P G, S, I G, S, P P G, S, P S, G D, S, I, P D, S, I, P D, S, P, I S, I, P D, S, I, P S, G S, G, I S, G, I S, I, P S, I, P D, S, I S, I, P P G, S, P G, I, P D, G, I, P D, G, I, P G, S, I, P G, I, P G, S, I, P D, S, G G, I, P G, I, P G, I, P G, I, P D, S I G, I, P S S SI P S, I, P S D, I S, I LEGEND A D G S Approve Develop Provide Guidance Support Implementation I F P Implement Follow Instructions Participate MD GM’s OSH Dept Site OSH Managing Director General Managers Perth Office OSH Team Site Safety Personnel Supply Spvrs Site Mngt Employees Purchasing Personnel Supervisors Site Management Verve Energy Employees 5 OSH Standard 1 – V1 ISSUED 28/3/11 OSH Standard 2 Safety and Health Planning Verve Energy's commitment to achieving the highest levels of OSH compliance consists of: • Achieving continuous improvement in performance by determining objectives and targets, and allocating resources to monitor the effectiveness of implementation of the OSH Management Plan. • Systems that will be documented in the OSH Management Plan and supplemented with a range of local initiatives that involve, challenge and motivate the workforce. • Incorporating OSH objectives into corporate and business planning processes and identifying and providing resources to achieve them. • Delegating to management and employees responsibilities and accountabilities for achieving OSH objectives. • Reviewing the OSH management performance results and incorporating improvement strategies into the planning process with the overall aim of improving outcomes. Managers will lead the Safety and Health planning process by: • Managing and being responsible for OSH at all stages of work. • Ensuring sufficient people and resources are available for the successful and timely implementation of OSH systems of work. Key Deliverables The implementation of this Standard involves: • Development of the Safety and Health Management Plan that determines the schedules, activities, resources, legal requirements and responsibilities with associated performance indicators necessary to achieve clear and measurable outcomes. • Setting, documenting, communicating, monitoring and reviewing measurable Safety and Health objectives, targets and performance indicators for each functional level. • Maintaining a workplace culture that embodies the OSH strategies. • Developing Safety and Health Plans that align to Safety and Health objectives and targets. These plans must ‐ clearly specify OSH risks and opportunities, identify allocated resources and define responsibilities and timeframes for achieving their goals. • Identifying all temporary and permanent changes that could have an impact on OSH. They will be documented, registered, risk‐assessed, authorised and communicated to affected stakeholders. • Employees understanding the Safety and Health Management Plan and their role and responsibilities. • Ensuring that the information, documents and data that affect Safety and Health within Verve Energy is adequately controlled, and that processes are in place to manage effectively amendments to the Safety and Health Management System. 6 OSH Standard 2 – V1 ISSUED 28/3/11 OSH Standard 3 Statutory and Other Obligation Management Verve Energy requires systems to be in place, and incorporated into all relevant systems of work, to ensure all statutory requirements, other Safety and Health obligations and industry codes and standards are identified, maintained, communicated, understood, accessible and complied with by management, employees and contractors. This Standard describes these obligations, actions, responsibilities and tools relevant to the operation of Verve Energy and consists of: • Evaluation of compliance with legal and other requirements at least every 2 years. • Communication of legal information and requirements to all stakeholders, in a language and style suitable for the purpose and audience. • Identifying responsibilities and liabilities of managers, directors, owners and employees and the consequences of non‐compliance. • Maintaining and securing records and record keeping systems to meet legal or statutory requirements. • Actions by each employee to improve their own work practice as a result of self‐evaluation, feedback from others or in response to changed work practices or technology. Key Deliverables The implementation of this Standard involves: • Systems to identify, assess, and regularly review all applicable legislation and other Safety and Health obligations. • Preparation of a Legal Register in which all relevant Safety and Health obligations are documented, maintained, accessible, communicated and periodically reviewed. • Appointment of a person responsible for identifying relevant legal requirements and advising management of any changes and actions necessary to achieve compliance. • Communication to all affected stakeholders of changes to statutory requirements, other Safety and Health obligations, industry codes and standards. • Maintaining an awareness of current and applicable legal, environmental and safety performance measuring and reporting requirements. • Procedures for raising a non‐conformance where legal or other obligations are identified as not being met. The non‐conformance will identify actions required to meet the obligation and a process for tracking the actions through to resolution. • Employees in a statutory position being provided with sufficient resources and training to discharge their responsibilities. • Senior Managers identifying and maintaining an awareness of their respective and relevant reporting requirements and reciprocal arrangements with industry associations. • Incorporating key legislative requirements into project plans. • All employees being made aware, through training, of their responsibilities, and the consequences of deviating from those responsibilities. 7 OSH Standard 3 – V1 ISSUED 28/3/11 OSH Standard 4 Risk Management Verve Energy is committed to providing and maintaining the best possible standard of safety and health at work sites for employees, contractors and visitors. Verve Energy will adopt a Risk Management approach that consists of: • A process that: is a continuous systematic method of identification and analysis, evaluation, control, monitoring and review; recognises situations which have the potential to cause harm to people, property, community or the environment; and initiates action to prevent the occurrence of a hazardous situation. • Hazards being proactively identified, risk‐assessed and appropriately managed on an ongoing basis. Adequate controls will be based on the application of the hierarchy of controls. • Verve Energy complying with the legislative requirements covering the management of risk in all its activities and ensuring continuous improvement of OSH for all employees. The risk management process will be implemented through a formal, consistent, structured and effective consultative process at each workplace as defined under the Occupational Safety and Health Act 1984, the Occupational Safety and Health Regulations 1996 and relevant Australian Standards. • Evaluating, managing and communicating all temporary and permanent changes to the organisation, personnel, systems, work instructions and equipment. This will ensure that resulting OSH risks are managed. Key Deliverables Implementation of this Standard involves: • A system to identify, assess, document, communicate and review Safety and Health hazards and associated risks for all stages of work, from planning through completion. The system will ensure that controls are implemented for the ongoing management of risk. • Risk assessment of the operational process to identify the hazards and controls. The output from risk assessments, risk control action plans and risk information will be recorded and updated on a Hazard Register at each workplace. The Hazard Register will ensure that a record of all hazards, and the means adopted to deal with them, is maintained. • Hazards/risks reviews at intervals determined by the level of risk. • Commitment, accountability, leadership and an understanding of responsibilities. • Management responsibility for ensuring that foreseeable workplace hazards are identified and that the risks from those hazards are assessed and controlled. • All employees while at work will, comply with their obligations under the Occupational Safety and Health Act 1984 and this OSH Standard 4, report workplace hazards or potential hazards, participate in the assessment and analysis of identified hazards as requested, and comply with the developed risk controls. • Documented procedures, consultation and active participation at all levels. • Allocation of appropriate resources and ongoing monitoring and evaluation of risks and processes of control. • Ensuring control measures are sustained by incorporating them into project expenditure, maintenance, or audit schedules. • Ceasing work where the risk cannot be managed appropriately. • Personnel Protective Equipment Standards being specified, communicated and monitored. 8 OSH Standard 4 – V1 ISSUED 28/3/11 OSH Standard 5 People Training and Behaviour Verve Energy’s commitment to ensure effective systems are in place to attract, select, assess, retain and train employees to meet the requirements of the company and to carry out their tasks safely, consists of: • A controlled employee relations framework and an effective and open communication process where potential conflicts are resolved pro‐actively and constructively. A training system which includes training needs analysis, training development and delivery to ensure employees receive relevant training for the tasks they are expected to perform. • All operational roles having essential occupational and on‐the‐job competency requirements identified through training needs analysis and being recorded in the training system as a qualification requirement for the role. • Providing sufficient information, instruction and training to employees to ensure that they can perform their work safely. The information, instruction and training must take into account the risk of the work and the competency of the employee. Supervision will be proportional to the risks of activities to be performed and to ensure people’s safety. Managers and Supervisors will be accountable for accomplishing this by: • Ensuring that employees and contractors have the appropriate competencies and behaviours to effectively and safely undertake the work and activities that they have been allocated. • Recognising employee’s capability, level of training, knowledge and experience during the selection process and provide additional training where required. • Providing necessary support to assist in employee relations management. • Ensuring that the lead time for new business activities allows effective recruitment and appointments to take place in accordance with OSH standards. Key Deliverables The implementation of this Standard involves: • A training system to identify, prioritize, plan, document and monitor Safety and Health training needs and to ensure all employees, contractors and visitors are competent to conduct their activities and behave in a safe and responsible manner. • A training gap analysis for employees moving into new positions or taking on added duties and responsibilities; and a training plan developed to address any gaps. • Training programmes and/or information being systematically reviewed and amended whenever a site and/or operation is impacted by change, including new equipment, processes and obligations. • Training programmes developed and delivered by people with the appropriate levels of knowledge, skills and expertise in the areas being covered. • People who are appointed or contracted to Verve Energy possessing or being in the process of acquiring the requisite competencies and behaviours. • Managing the training of all employees through a training matrix. Ensuring that induction programmes and associated refresher training courses for employees, contractors and visitors address relevant OSH objectives, hazards, risks, controls, and behaviours. • Ensuring the results of pre‐placement medicals of all employees are reviewed against associated task risks. • The Safety and Health competency requirements for all positions being defined and documented and competency being assessed in a consistent manner. • A task observation programme that reinforces desired OSH behaviour and reduces at‐risk behaviour. 9 OSH Standard 5– V1 ISSUED 28/3/11 OSH Standard 6 Safety and Health Communication and Consultation Verve Energy’s commitment to promote a positive OSH culture involving and motivating individuals to think and act in a safe manner consists of: • An effective two‐way communication and consultation process on Safety and Health matters that allows the free flow of information with all internal and external stakeholders in a professional, consistent and expedient manner. • Consultation within the workforce and with key stakeholders to promote feedback regarding OSH activities. • Verve Energy communicating verbally, by written notification or by use of company notice boards. Key Deliverables Implementation of this Standard involves: • A system to ensure employee involvement and consultation on matters that may affect their safety and health. Procedures for communication and consultation will be maintained and reviewed as necessary with input from employees. • A mechanism for communicating with external parties such as community representatives and regulators. This will be an open process and allow for two way dialogue, which is recorded and documented. • Regular meetings with representatives from all throughout Verve Energy. The meetings will: Promote safe and healthy sound work practices. Increase awareness and commitment. Obtain views from employees. Resolve emerging problems. Monitor OSH performance. • An established Conflict Management and Issue Resolution process. • Evaluations of the effectiveness of the communication and consultation process. • Consulting with employees, so far as is reasonably practicable, before making any decision or change in relation to their health and safety in the workplace. • Suggestions for change and improvements to policies, procedures or safe work practices being encouraged, through reporting to management. • An employee will not be penalised in any way for reporting safety matters or refusing to work in demonstrably unsafe conditions. • Compliance with requirements to display and communicate identified information. Safety and Health information will be shared between workplaces and branches. • Safety and Health Policy, Standards and relevant OSH information, including risks, controls, plans, and performance being communicated to employees, contractors and other interested parties regularly. • All employees and contractors being consulted and cooperating with safety and health related matters, communicate any instances of hazards or incidents in the workplace and provide feedback on the effectiveness of established consultation and communication. 10 OSH Standard 6 – V1 ISSUED 28/3/11 OSH Standard 7 Safe Systems of Work Verve Energy’s commitment to ensure all plant and equipment is operated and maintained in a manner which minimises hazards and risks, consists of: • Operational standards and practices of operating plant being aligned with the highest industry standards and with regulatory requirements. All plant and equipment will be designed and constructed to appropriate Australian or National Standards and used only for the purpose for which they were designed. • All plant and equipment having documented operating procedures and being operated, maintained, inspected and tested to manage OSH risks. Facilities will be operated and maintained within the approved design to ensure safe and healthy performance and compliance with all applicable laws, regulations and permits conditions. • Systems, procedures or practices, that manage risk in operations and maintenance activities, being implemented, maintained and periodically reviewed. This will ensure they continue to be adequate and effective. Documented design data and operating limits must be understood, available and reviewed at a frequency based on risk. Key Deliverables The implementation of this Standard involves: • Systems and procedures ensuring that operations and maintenance activities are conducted in a manner that ensures Safety and Health hazards and risk are minimised. Formal programmes will outline requirements to monitor the key characteristics of the operations and activities that can cause illness and injury. • Preparation of start‐up, operating, maintenance, and shutdown procedures (e.g. Permit to work, lockout/tag out, equipment hand over, confined space entry, equipment and process isolation etc.) with defined accountability and responsibility. These procedures will be developed based upon the nature of the hazard and the particular operation. They will be monitored regularly. • Maintenance, inspection, testing, calibration and certification of plant and equipment being conducted at frequencies based on risk associated with the equipment, legal and manufacturers’ requirements. • Maintenance personnel and operators will be suitably qualified, experienced and competent. • Ensuring that the appropriate technical drawings and documentation are available and up to date. • MSDS for all chemicals in use, being available, easily accessible and up to date. • Identification and documentation of critical equipment, systems, procedures and activities being completed prior to commissioning or return to service. Critical systems, such as shutdowns, relief controls and alarms, will be tested and undergo preventive maintenance. • Ensuring pre‐start checks are conducted. • All subcontractor equipment will be checked before use on site. • Ensuring all equipment is recorded on a maintenance register and monitored for periodic servicing. • Ensuring all employees and subcontractors recognise what constitutes a change; and understand that all changes must be authorised. Changes include those to plant, processes, procedures, design, layout and operating methods. 11 OSH Standard 7 – V1 ISSUED 28/3/11 OSH Standard 8 Working with Contractors, Suppliers and Partners Verve Energy’s commitment to ensure that the requirements of the Verve Energy Safety and Health Management Standards are complied with in respect to the contracting of services, the purchase of goods and the activities of partners, consists of: • The contracting of services, the purchase, hire or lease of equipment and materials, and activities with those contractors, suppliers or vendors, being carried out so as to minimise any adverse consequences. • Verve Energy providing to contractors information about safety and health expectations, requirements, or policies and procedures used throughout Verve Energy. Contracts will specifically require contractors to implement systems consistent with this Standard, manage assessed OSH risks and comply with relevant legislation. • Consequence of non‐compliance being clearly communicated. Contractors must: ensure orderly conduct of all work; that the final product delivered as part of the contract is “fit for purpose”; the safe use of plant and substances supplied by them or provided by Verve Energy for use, and that their activities do not put at risk the health and safety of their employees or subcontractors, Verve Energy employees or others who may be affected by the activities. Key Deliverables The implementation of this Standard involves: • A process for selecting competent contractors. This should consider whether contractors are technically and professionally competent, have adequate and appropriate insurances, operate adequate OSH management systems and have satisfactory OSH performance that matches Verve Energy targets. • Compliance with the provisions of this Standard, other OSH policies and procedures and other related requirements of all legislation, relevant regulations and Australian Standards, Codes of Practice and Guidance Notes and the manufacturer's guidelines as applicable. • Ensuring systems are in place that ensure the performance of contractors, suppliers and partners, and that their compliance with the OSH obligations specified in their contracts, is monitored and reported. • Contractors demonstrating their suitability for the specific work to be completed and a capacity to comply with this Standard having the required experience and possessing all necessary licences, permits and registrations. • Contractors’ providing any information including documentation that addresses any matters requested by Verve Energy and completing the required induction or training as specified. • Providing adequate supervision of Contractors, employees or other persons under their control. • Establishing and documenting the reporting relationships, lines of communication, responsibilities and system interfaces between contractors, suppliers or partners and Verve Energy. • A process to ensure that materials, equipment and services procured comply with OSH requirements and present the least risk to people. The specifications of equipment and materials that have potential OSH impacts will be documented prior to purchase, hire or lease. Compliance with these requirements will be verified. • Hazards associated with equipment, products and services supplied and the activities carried out by contractors being identified, assessed and controls implemented where necessary. Dependent on the risk, a Safety and Health evaluation will be carried out prior to the contractual arrangements being established with contractors, suppliers or partners. • Post contract evaluation processes of suppliers, contractors and partners being established, monitored, reported and actioned as required and preferred supplier status being considered. 12 OSH Standard 8 – V1 ISSUED 28/3/11 OSH Standard 9 Occupational Health Management Verve Energy is committed to providing a healthy workplace as a result of successful programmes and support services that address the physical and psychological wellbeing of employees. Verve Energy will adopt an Occupational Health Management approach that consists of: • A system that clearly identifies the procedures, responsibilities, resources, training and competencies required for managing Fitness for Work. • A risk‐based approach that defines medical and physical assessments to ensure all personnel are medically and physically fit to perform their job functions. • Preventing and minimising the harm that can be caused at work by alcohol and drugs. • Preventing and minimising the adverse effects at work of fatigue, working hours and excessive hours. Key Deliverables The implementation of this Standard involves: • Occupational health programmes that ensure systems are in place for the effective assessment and treatment of injuries. All employees are required to report for work in a fit condition to perform their required duties in a safe, competent and efficient manner. • Pre‐employment assessment of fitness for work against risk based determined criteria being conducted to measure a prospective employee’s or contractor’s fitness for work prior to any offer of an employment contract being made. This includes medical and physical assessments and a pre‐ employment alcohol and other drug screen. All medical and personal information will remain secure and confidential. • Promotion and education of mental, emotional and physical health. • For cause drug and alcohol testing being implemented where there is belief that an individual’s fitness for work may have been a contributing factor to an accident or incident, where an individual’s unusual or inappropriate behaviour raises concern or where any evidence is found of possible alcohol or other drug use at work. • A random drug and alcohol testing programme being implemented. • The potential for fatigue and associated risks being identified and controlled. Verve Energy will take all practicable steps in the placement of employees to ensure the hours of work, shifts/rosters and workplace conditions do not create an unacceptable risk of fatigue. • Health surveillance of the workforce consistent with exposure risks being implemented and recorded and kept current. • Programmes including rehabilitation for employees recovering from a work related injury or illness. • Programmes to encourage employees to return to the workplace where they can make a valuable contribution to the organisation. • All employees and contractors having access to adequate medical and first aid services. • All employees having access to employee assistance counselling. • Maintaining general health, hygiene and sanitation facilities and procedures. • Compliance to local regulatory requirements for the management of workers compensation. • Development of an occupational hygiene monitoring programme. The monitoring programme will be based on potential and likely contaminants present in Verve Energy operations. Results of the monitoring programme will be communicated to employees. 13 OSH Standard 9 – V1 ISSUED 28/3/11 OSH Standard 10 Learning from Incidents Verve Energy is committed to reporting, investigating and analysing all relevant incidents to ensure corrective and preventive actions are taken and lessons shared. This “Learning from Incidents” approach consists of: • Systems allowing the timely reporting, recording, investigation and analysis of all Safety and Health incidents. Incidents will be thoroughly investigated and analysed, causes identified and corrective actions planned. • Systems allowing the timely feedback, communication and sharing of information and lessons from incidents. Managers and Supervisors will be held accountable for accomplishing this Standard by: • Ensuring that appropriate employees receive suitable training to carry out their role in hazard and incident reporting, investigation and recording. • Promptly reporting and investigating incidents in their area of responsibility and accountability. • Completing and submitting Hazard or Incident Investigation Reports as soon as practicable and within designated time lines. • Implementing identified risk control measures to prevent recurrence of incidents. • Consulting with employees in relation to the measures to be taken to prevent recurrence of incidents. • Reviewing hazard/incident reports for their area to ensure that all recommendations are implemented. • Ensuring, as far as is reasonably practicable, that adequate resources are made available to institute the recommended actions. Key Deliverables The implementation of this Standard involves: • A system to carefully identify all causes of an incident or hazard and identify how to prevent injury, damage to property or loss of life. • An employee notifying their supervisor immediately an incident occurs in the workplace. All incidents are to be reported. • Reporting and investigating OSH incidents. Information gathered from investigation of incidents will be analysed to monitor trends and identify lessons which will be communicated to affected stakeholders. • The investigation delivering outcomes to correct the basic causes of incidents and any systems failures. The investigation will identify any areas that require development, change or modification. • All incidents being reported verbally immediately or when able to do so safely. • The relevant manager, on receipt of an incident report, determining the severity of the incident immediately arranging for an investigation to be commenced and if necessary assisting injured workers to lodge a workers' compensation claim. • Corrective and preventive actions arising from incident investigations being implemented, recorded, tracked to completion, and their effectiveness assessed. • A Senior Manager being delegated the strategic responsibility for implementing, reviewing and amending the incident and hazard reporting procedures. • Disseminating to appropriate personnel, the relevant information arising from hazard and incident investigations. 14 OSH Standard 10 – V1 ISSUED 28/3/11 OSH Standard 11 Emergency Management Verve Energy's commitment to ensure procedures and resources are in place to respond effectively to workplace emergency situations consists of: • Identifying all foreseeable emergency incidents and having formal response procedures developed and documented. Where assistance from external emergency services may be required, ensuring these services are familiar with the project, type of potential incidents and site communication systems. • Documented plans that define accountabilities, resources and response, including the mitigation of OSH impacts for foreseeable emergency scenarios being implemented, regularly tested and maintained. • All potential emergencies and their impacts for each workplace being considered and risk assessed. • An Emergency Response Plan being developed in consultation with relevant internal and external stakeholders, documented with clearly defined roles and accountabilities, communicated and made accessible to everyone at the workplace and periodically tested and evaluated for its adequacy. Key Deliverables The implementation of this Standard involves: • Identifying potential emergencies that may occur, based upon the location and nature of the operation. • Developing, documenting, implementing, communicating and testing emergency plans and procedures to minimise the likelihood and severity of any emergency that may arise. • Arrangements to provide for effective interfacing with stakeholder procedures, where necessary, and communications with next of kin, the media, police and regulators as appropriate. • Exercises and drills at predetermined intervals to measure adequacy of procedures and to put in place procedural improvements that may be necessary. • Emergency response equipment being well maintained, routinely inspected and tested. • Recovery plans being documented and implemented. • Appropriate resources being identified both on and off site to ensure effective implementation of the Emergency Response Plans. • All relevant personnel, contractors and visitors being trained in their roles and responsibilities. • An effective alarm and communication system being installed at each workplace to allow the emergency personnel to communicate with site personnel to ensure an orderly and well executed evacuation. • Work associated with a significant incident or emergency being suspended until resumption is authorised by the responsible manager. • A formal review after each critical incident or emergency drill being conducted and recorded. • Ensuring emergency related equipment and procedures are included on project inspection registers and checklists. Back up equipment is to be accessible and available specifically if there is an escalation in an evolving situation. • Ensuring that first aid requirements as specified in MSDS’s are available with the capacity and facilities to deal with specific hazards not identified in generic first aid assessments. • Information gathered from incident investigations being analysed to monitor trends, identify lessons and communicated to affected stakeholders. • Hazard Alerts being distributed to ensure the understanding of contributory causes and corrective actions is well understood. 15 OSH Standard 11 – V1 ISSUED 28/3/11 OSH Standard 12 Audit and Review Verve Energy's commitment to ensure that Safety and Health systems and performance are audited and reviewed to drive continuous improvement consists of: • Regular formal and informal audits and inspections being undertaken at all levels of Verve Energy to ensure compliance with standards, procedures and practices and to minimise adverse impacts. • OSH performance measures and reporting requirements including legal obligations being defined and implemented. • Performance and systems being monitored, audited and reviewed to identify trends, measure and report progress, assess compliance and drive continual improvement. • Performance measures being clear, sufficiently detailed and including a data source and/or reporting method that will allow results to be accurately assessed. Key Deliverables The implementation of this Standard involves: • An annual audit programme tailored to the needs of the company that indicates the frequency and the areas to be audited. Inspections and audits of activities and systems being conducted at frequencies determined by the level of risk. • Audits being carried out by trained personnel who ideally are independent of the area being audited. External parties may be called upon from time to time to conduct third party verification audits. • Inspection programmes with associated checklists being carried out by competent personnel who satisfy regulatory requirements. • Corrective action systems to ensure defects are rectified within an acceptable time. • Managers implementing and managing a system of internal audits to ensure all systems and processes, especially those containing critical controls, are fully maintained. • Senior Managers reviewing audit reports to satisfy themselves that the total audit process reflects the operational status of the organisation. Audit findings will be used to reset OSH goals and implement improvements to OSH Management System. • Management reviews being carried out and corrective actions identified. Management will periodically review OSH audit trends and OSH policies. • Critical statutory inspections of the site being detailed and scheduled. • The OSH Monthly Status Report being produced and referencing data from site registers (KPI's) and statistics for the current period. The report will be reviewed by the responsible Manager prior to publication. • Ensuring verification of status of equipment for calibration and maintenance; establishing the calibration register and documents history. • Each Performance Improvement Plan being monitored with sufficient intensity to ensure that high priority improvements requiring immediate attention are implemented by the agreed time. • The continuing suitability, effectiveness and adequacy of the Safety and Health Management System being reviewed annually by the Verve Energy Executive Committee for Safety and Health. 16 OSH Standard 12 – V1 ISSUED 28/3/11 SAFETY AND HEALTH MANAGEMENT SYSTEM VERVE ENERGY SAFETY AND HEALTH MANAGEMENT SYSTEM SAFETY AND HEALTH MANAGEMENT GUIDELINE LEADERSHIP & ACCOUNTABILITY SAFETY AND HEALTH PLANNING STATUTORY AND OTHER OBLIGATIONS MANAGEMENT RISK MANAGEMENT PEOPLE TRAINING AND BEHAVIOURS SAFETY AND HEALTH COMMUNICATION & CONSULTATION SAFE SYSTEMS OF WORK WORKING WITH CONTRACTORS, SUPPLIERS AND PARTNERS OCCUPATIONAL HEALTH MANAGEMENT LEARNING FROM INCIDENTS EMERGENCY MANAGEMENT AUDIT AND REVIEW CONTRACTOR MANAGEMENT PLANNING WORKERS COMPENSATION AND REHABILITATION INCIDENT REPORTING AND INVESTIGATION EMERGENCY MANAGEMENT PLANNING CORPORATE SAFETY MANAGEMENT SYSTEM AUDIT PLANNING DATA / TREND ANALYSIS CRITICAL INCIDENT RECOVERY PLAN INTERNAL AUDIT PLANNING FORMS, CHECKLISTS & REGISTERS EXTERNAL AUDITS Management System Sub-elements ORGANISATIONAL STRUCTURE SAFETY AND HEALTH MANAGEMENT PLANNING LEGAL AND OTHER REQUIREMENTS HAZARD AND RISK MANAGEMENT TRAINING MANAGEMENT PLANNING SAFETY AND HEALTH POLICY OBJECTIVES AND TARGETS WORKSAFE INTERNAL INSPECTIONS INDUCTION TRAINING CONFLICT MANAGEMENT AND ISSUE RESOLUTION HAZARDOUS SUBSTANCES MANAGEMENT PURCHASING GOODS AND SERVICES FIT FOR WORK SAFETY AND HEALTH MANAGEMENT STANDARDS SCHEDULES LEGISLATIVE UPDATES PROJECT RISK MANAGEMENT TRAINING DEVELOPMENT AND ASSESSMENT MEETINGS HIGH RISK OPERATIONS OUTAGE ASSESSMENTS FIRST AID TARGETED INCIDENT REDUCTION PLANS DOCUMENT CONTROL FORMS, CHECKLISTS & REGISTERS CRITICAL RISK CONTROL PERFORMANCE PLANNING COMPETENCY ASSESSMENTS SAFETY REPRESENTATIVES MOBILE PLANT AND EQUIPMENT FORMS, CHECKLISTS & REGISTERS HEALTH PROMOTION FORMS, CHECKLISTS & REGISTERS ROLES AND RESPONSIBLITIES CONSULTATION AND COMMUNICATION INTEGRATED SAFE SYSTEMS OF WORK ERGONOMICS OCCUPATIONAL HYGIENE POSITIONS DESCRIPTIONS PERFORMANCE INDICATORS SAFETY AND HEALTH CAPITAL PROJECTS BEHAVIOURAL PROGRAMME NOTICEBOARDS GOLDEN RULES CHANGE MANAGEMENT FORMS, CHECKLISTS & REGISTERS FORMS, CHECKLISTS & REGISTERS INTERNAL AND EXTERNAL REPORTING TRAFFIC MANAGEMENT HEALTH SURVEILLANCE PROMOTIONAL ACTIVITIES AND EVENTS PERSONAL PROTECTIVE EQUIPMENT FUNCTIONAL CAPACITY ASSESSMENT PROGRAMME FORMS, CHECKLISTS & REGISTERS FORMS, CHECKLISTS & REGISTERS FORMS, CHECKLISTS & REGISTERS FORMS, CHECKLISTS & REGISTERS 17 Safety and Health Management System – V1 MANAGEMENT REVIEWS FORMS, CHECKLISTS & REGISTERS FORMS, CHECKLISTS & REGISTERS Issue Date 28/03/11