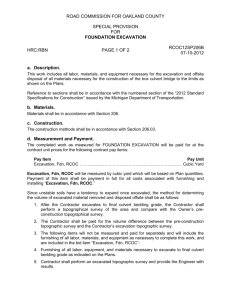

Culvert Replacement Method Statement

advertisement