Woolley Hill Wind Farm: Construction Method Statement

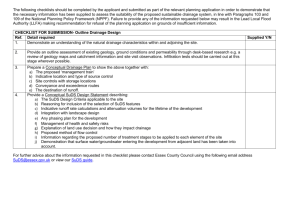

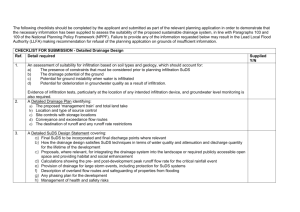

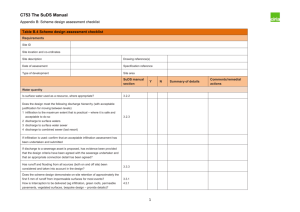

advertisement