END MILLS

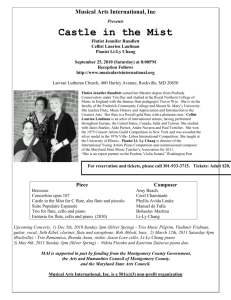

advertisement