NEW STERLING LOOK NEW PRODUCT NEWS

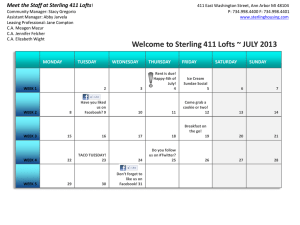

advertisement

May 2012 Midway through the second quarter and the year is flying by! From engineering and design to manufacturing and marketing, the entire Sterling team is working together to bring you outstanding products along with all the necessary support materials. IN THIS ISSUE New Sterling Look New ERMS Unit In this edition of the Sterling HVAC News, you'll find information on our newest products and literature along with an update on progress at the Mestek Development Center. Finally, please join us in congratulating everyone at our Farmville plant as they are named Industry of the Year! The accolades are well earned by each and every member of the plant. Industry of the Year Mestek Development Center We aim to provide you with the best possible products and services available! Sterling Marketing Services NEW STERLING LOOK Keep your eye out for our new Sterling HVAC Products logo. As we release new products and revised literature, we will be including our new logo. Additionally, we are in the process of updating much of our literature to include sales specific brochures and separate application manuals featuring pertinent technical data. We will send notification to the field as literature becomes available. Feel free to update your websites, line cards and support materials with the new logo. . NEW PRODUCT NEWS ENERGY RECOVERY MODULE You asked for it and we have it! Our new Energy Recovery Module is now available to team up with our Engineered Product offering to provide the most energy efficient make up air system available on the market today. Available for new, retrofit or even standalone, the ERMS Series is an outdoor rooftop mounted electrically controlled outdoor preconditioner which recovers conditioned air, reducing the load placed on an HVAC system by untreated air. Equipped with a supply fan as well as the return fan, the system produces industry leading efficiencies of 70 - 85%, depending on design conditions. At the heart of the ERMS unit is the energy recovery wheel which transfers energy from the warmer to the cooler air stream through counter-flowing supply and exhaust air streams. The slowly rotating wheel (less than 60 revolutions per minute) transfers moisture entirely in the vapor state, eliminating wet surfaces that retain dust and promote fungal growth. The ERMS submittal along with the brochure (ERMS-1) are available on the Mestek Sales Assistant. SEPARATED COMBUSTION UNIT HEATER Also now available are our new "SC" blower type and "SF" propeller type tubular separated combustion unit heaters. Offering a highly efficient, extremely durable alternative to the traditional clam shell design, these units offer application flexibility for areas in which dusty, dirty or mildly corrosive conditions exist or where high humidity or slightly negative pressures are prevalent. Nine sizes with inputs ranging from 100 - 400 and efficiencies of 82 - 83% make this a very competitive product line. The SF/SC submittal along with the brochure (TSF/C-1) will be available on the Mestek Sales Assistant within the next few days. INDUSTRY OF THE YEAR Please join us in congratulating our hard working staff at the Farmville, NC plant who recently celebrated being named Industry of the Year 2011-2012 for Pitt County. According to Plant Manager Emerson Hobgood, it was a proud day for everyone at the facility. "This is a prestigious award which we all earned as a team. Recognition like this goes a long way with the workforce," Hobgood said. Spirits soared as all employees were gathered together along with reporters from every major news outlet in the area for the announcement. Hobgood credits the success of the facility to a corporate culture of team building and continuous improvement through programs including Mestek's EPIC Challenge, a companyFarmville Plant Manager Emerson Hobgood, chats with wide initiative which includes quality benchmarks that must be employees as they celebrate their Industry of the Year met in order to achieve operational excellence status. Award. Farmville has already met many milestones in this initiative, such as receiving the prestigious North Carolina Department of Labor certificate of safety achievement award. "Offering the best products with the best price and the best lead time is our primary goal as well as our competitive advantage in a highly competitive market," says Hobgood. The Farmville facility opened in 1974 and now has 168 employees. Approximately 40% of their current workforce have over 25 years of service at the company. This strong team of experienced employees has helped the Farmville plant remain a flagship Mestek facility. The Farmville facility is known for being engaged in the community and giving back generously to its neighbors. "Mestek has been a valued corporate citizen in our community since 1974. There are very few companies here or anywhere in the country which have that kind of longevity and community commitment," said Wanda Yuhas, Pitt County Development Commission (PCDC) executive director. "We are thankful for their many investments here and for employing so many of our citizens." "The past year was very challenging for many businesses," says Scott Poag, PCDC existing industries coordinator. "Mestek focused on improving the aspects of their business they were able to control and this has contributed to their success." Hobgood credits the success of the facility, in part, to the reinvestment of earnings back into the company for new and improved products, related acquisitions and market development. Over the past two years, Mestek has provided training to more than 140 employees through a partnership with Pitt Community College. Additionally, specific annual goals for waste reduction and environmental conservation as well as the investment of significant resources in R&D for higher efficiency products is certainly paying off. Congratulations on a job well done! MESTEK DEVELOPMENT CENTER NEWS Our Sterling engineering and design team has been hard at work in the lab on new products, product enhancements and extensions to the product line. 2012 is already proving to be an exciting year. Our new rooftop proof of concept unit has logged well over 500 hours of outdoor testing without issue. Efficiencies of the test unit are exceeding preliminary projections which will make the new rooftop project the most efficient in the industry. The design team is now building the prototype unit for ETL construction review. Based on current progress, we anticipate having the new rooftop available for sale by the end of the fourth quarter. New rooftop proof of concept unit logging in over 500 test hours. We are also currently working on a high efficiency unit heater. The prototype heat exchanger is complete and testing has begun. The new unit promises to offer ultrahigh efficiencies along with a reduced footprint. Other work in the lab includes developing a high efficiency tubular duct furnace as well a cold weather enclosure for the variable frequency drive offered on our engineered product line. The cold weather enclosure will offer built in electric heat and will be available for the next heating season. Stay tuned for more details as the year progresses. Sterling HVAC 260 North Elm Street Westfield, MA 01085 Phone: 413-564-5540 Fax: 413-562-5311 www.sterlinghvac.com