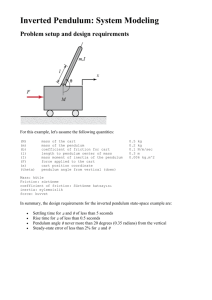

FPGA-Based Model of an Inverted Pendulum for Hardware-in

advertisement