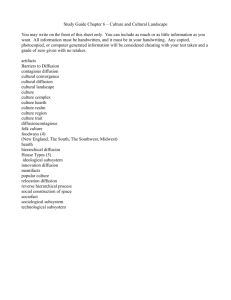

View/Open - Victoria University of Wellington

advertisement