Polymer 54 (2013) 4143e4154

Contents lists available at SciVerse ScienceDirect

Polymer

journal homepage: www.elsevier.com/locate/polymer

Maleic anhydride functionalization of polypropylene with suppressed

molecular weight reduction via solid-state shear pulverization

Mirian F. Diop a, John M. Torkelson a, b, *

a

Dept. of Chemical and Biological Engineering, Northwestern University, Evanston, IL 60208, USA

Dept. of Materials Science and Engineering, Northwestern University, Evanston, IL 60208, USA

b

a r t i c l e i n f o

a b s t r a c t

Article history:

Received 7 March 2013

Received in revised form

29 May 2013

Accepted 3 June 2013

Available online 12 June 2013

Polypropylene (PP) is sometimes functionalized with polar molecules like maleic anhydride (MA) to

improve interfacial adhesion and to allow for reactive compatibilization. The conventional method of

synthesizing PP grafted with MA (PP-g-MA) is by post-polymerization reactive extrusion at high temperature (180e220 C). Under these conditions, the extent of b-scission (a radical chemistry that results

in cleavage of CeC backbone bonds) is significant; thus, the product of functionalization by reactive

extrusion suffers dramatic molecular weight (MW) reduction and degradation of properties. We present

a novel method of synthesizing PP-g-MA while strongly suppressing MW reduction using solid-state

shear pulverization (SSSP). By taking advantage of the relatively low temperature conditions associated with SSSP and with the use of azobisisobutyronitrile as radical initiator, significant MA grafting

levels are achieved while strongly suppressing b-scission. For a PP-g-MA sample with 0.5 wt% grafted

MA, characterization of number-average MW (Mn) before and after functionalization reveals that the

frequency of chain scission events per repeat unit is reduced by more than 90% when synthesis is done

by SSSP as opposed to reactive extrusion. Consequently, relative to the neat PP from which it was made,

the PP-g-MA sample (with 0.5 wt% grafted MA) synthesized via SSSP exhibits only 8 and 25e32% reductions in Mn and weight-average MW (Mw), respectively; this is greatly improved over the 51 and 71%

reductions in Mn and Mw reported in the literature for PP-g-MA (with 0.5 wt% grafted MA) synthesized

by reactive extrusion.

Ó 2013 Elsevier Ltd. All rights reserved.

Keywords:

Functionalization

Chain scission

Polypropylene

1. Introduction

Polyolefins are non-polar, resulting in excellent chemical resistance. Though often advantageous, this non-polar nature is a

disadvantage in applications requiring compatibility and adhesion

between polyolefins and polar molecules [1]. As a result, there has

been great interest in functionalizing polyolefins with polar molecules [1e14], including itaconates [2], methacrylate esters [3],

maleic anhydride (MA) [4e10], peroxyketals [11,12], and peroxyesters [13,14]. The most common functionalized polyolefin is

isotactic polypropylene (PP) grafted with MA (PP-g-MA), which is

useful as a compatibilizer for blends [15e17], composites [18e20],

and nanocomposites [21e23] or as an asphalt modifier [24,25].

Unfortunately, as practiced commercially, functionalization is

accompanied by harsh effects which have proven difficult to

* Corresponding author. Dept. of Chemical and Biological Engineering, Northwestern University, Evanston, IL 60208, USA.

E-mail address: j-torkelson@northwestern.edu (J.M. Torkelson).

0032-3861/$ e see front matter Ó 2013 Elsevier Ltd. All rights reserved.

http://dx.doi.org/10.1016/j.polymer.2013.06.003

overcome. As stated by Boaen and Hillmyer [26], “The incorporation of functional groups along the backbone of polyolefins such as

polyethylene and polypropylene in a selective, controlled, and mild

manner is one of the most important challenges facing synthetic

polymer chemists today.”

Polyolefins have been functionalized via two categories of

methods [1,26]. The first is direct copolymerization of a-olefins

with functionalized olefins [26e28]. A major issue with this

method is the tendency for O- and/or N-containing functional

groups to deactivate the polymerization catalysts, making it inappropriate for commercial application [1]. Catalysts, e.g., Ti, Zr, Cr,

and V, that interact strongly with functional groups have high

oxophilicity. In an attempt to remedy this problem, much less

oxophilic transition metal catalysts such as NiII and PdII have been

used [27,29]; in other cases, functional groups have been protected

before reaction (to minimize catalyst interactions) and then deprotected after functionalization [30e32]. Another method of

direct copolymerization uses an olefin and a monomer with latent

reactivity which is functionalized in subsequent processing steps

[33e38]. This method results in loss of stereoregularity control

4144

M.F. Diop, J.M. Torkelson / Polymer 54 (2013) 4143e4154

and/or requires multiple-step functionalization [1,26]. These challenges associated with direct copolymerization render this group of

methods unsuitable for commercial production of functionalized

polyolefins. The second category employs post-polymerization

processing where chains are modified with radicals that react

with polar molecules. This approach is accompanied by undesirable

side reactions (e.g., chain scission, cross-linking, and branching

[1,26]) which lead to compromised properties [26]. Although postpolymerization processing is used commercially for polyolefin

functionalization, it is far from ideal as currently practiced.

A hybrid approach has also been investigated involving the

synthesis of propylene copolymers containing units that allow for

post-polymerization functionalization [39e41]. Studies with

borane-containing copolymers showed that spontaneous oxidation

of borane units led to polymeric radicals that could be functionalized with a polar moiety [39]. A second attempt involved copolymerization of p-methylstyrene with propylene by ZieglereNatta

catalysis, followed by free radical grafting of a polar group to the pmethylstyrene unit via a suspension reaction using dicumyl

peroxide as initiator [40]. Unfortunately, these investigations yielded materials without advantages over those in commercial production because functionalization was limited to low molecular

weight chains [40] or because of the lack of commercial availability

and handling issues associated with reagents [39]. While our

manuscript was under review, a manuscript by Zhang et al. [41] was

published online that describes the production of a copolymer of

propylene with p-(3-butenyl)toluene which, after a suspension

reaction, can yield PP-g-MA [41]. Though significant reductions in

undesirable side reactions (such as chain scission) were observed,

the bulky comonomer reportedly resulted in significant reductions

in melting temperature and crystallinity.

Industrial production of PP-g-MA is done by melt processing or

reactive extrusion [8e10,42e44], resulting in post-polymerization

functionalization above the PP melt temperature (165e170 C). At

such temperatures, PP macroradicals formed during the functionalization process have the propensity to undergo rearrangement

resulting in scission into two shorter chains (i.e., b-scission); see

Scheme 1 [45e50]. b-scission is highly temperature dependent; the

rate of b-scission increases by eight orders of magnitude upon

increasing temperature from 25 to 200 C [45,46]. Thus, PP functionalization by melt processing results in significant b-scission and

molecular weight (MW) reduction. For PP-g-MA made by reactive

extrusion at 180e190 C and analyzed by high-temperature gel

permeation chromatography (high-T GPC), Shi et al. [8] reported

reductions in weight-average MW (Mw) of 67, 71, and 76% at 0.38,

0.51 and 0.78 wt% grafting levels, respectively. Such MW reduction

can diminish the properties of PP-g-MA as compared to those of the

neat PP from which it is synthesized. For example, Hasegawa et al.

[21] reported improvements in mechanical properties of a PP-gMA/clay nanocomposite over those of neat PP-g-MA. However,

because of the low PP-g-MA MW, the nanocomposite mechanical

properties were only comparable to those of neat PP.

Studies have used a variety of post-polymerization methods in

attempts to suppress chain scission and thus MW reduction associated with the synthesis of PP-g-MA. Some approaches resulted in

no suppression or even reported enhancements of MW reduction

relative to PP-g-MA made by conventional melt processing or

reactive extrusion [51,52]. One method achieved some chain scission suppression but at the cost of dramatically reduced PP isotacticity and crystallinity [53], which leads to major losses in

properties. Two studies reported some success in suppressing MW

reduction without loss of tacticity [54,55]. In one study, a continuous method with commercial potential resulted in PP-g-MA with

Mw values that may be interpreted as only 6e15% higher than those

for PP-g-MA samples made by conventional reactive extrusion with

equivalent MA content [54]. Using batch, solid-state ball milling,

another study produced PP-g-MA that, in some cases, showed

suppression of chain scission relative to melt processing but in

other cases resulted in “intensively” cross-linked material [55]. For

systems that were not described as cross-linked, e.g., PP-g-MA with

0.6e0.9 wt% MA, [55], the Mw values could nevertheless be interpreted as being reduced by more than 50% relative to the neat PP

starting material, which emphasizes the need to address the challenge of chain scission and MW reduction in a different way.

(A detailed description of these studies is provided in Section 2.

Background.)

Here, we show that solid-state shear pulverization (SSSP), a lowtemperature, continuous process with potential for high

throughput, provides a route for overcoming the scientific challenge of suppressing MW reduction while yielding PP-g-MA in a

commercially amenable manner. This process uses a twin-screw

melt extruder modified with a cooling system to maintain the

polymer in the solid state [50,56e64]. Although a much milder

solid-state process than ball milling, SSSP is accompanied by sufficient shear stresses and compressional forces to cause repeated

fragmentation and fusion of material; conditions are tuned by feed

rate, screw speed, screw design, and temperature [56]. In addition

to being solventless, SSSP is industrially scalable. (Polyolefins have

been processed by SSSP at Northwestern University with a

commercial-scale apparatus at rates exceeding 150 kg/h.) Compatibilization and intimate mixing of immiscible blends [57e60] and

effective dispersion and exfoliation in composites and nanocomposites can result from SSSP [61e65]. Here, by using SSSP in

post-polymerization synthesis of PP-g-MA, we present a platform

of chemistries that is unattainable with high-temperature processing. We show that the low-temperature radical chemistries

afforded by SSSP allow us to functionalize PP while maintaining

crystallinity levels and suppressing MW reduction to a much

greater level than achieved by other methods. Thus, SSSP demonstrates that it can meet the challenge of functionalizing PP in a

selective and mild manner.

2. Background: previous research on suppressing chain

scission and MW reduction in the post-polymerization

synthesis of PP-g-MA

Scheme 1. Mechanism for b-scission.

Over the past decade, several methods have been studied to

suppress the MW reduction associated with post-polymerization

PP-g-MA synthesis by free radical chemistry. Using brominated

reagents, Henry et al. [53] achieved some suppression; as characterized by high-T GPC, Mw was reduced by 81% at 1.25 wt% grafted

MA for reactive extrusion without brominated reagents and by 60%

at 2.47 wt% grafted MA with brominated reagents. Unfortunately,

the brominated reagents led to loss of PP isotacticity resulting in a

78% reduction in crystallinity relative to the neat PP from which the

M.F. Diop, J.M. Torkelson / Polymer 54 (2013) 4143e4154

PP-g-MA was made. Such a major reduction of PP crystallinity

drastically compromises mechanical and physical properties.

Functionalization employing solvent has also been studied for

its potential to suppress MW reduction in the synthesis of PP-g-MA.

Batch processes involving grafting in solution [6] or during solventbased swelling [51] (also called solvent-assisted solid-state grafting

[51]) can be done at temperatures below the bulk PP melt temperature, which should reduce the rate of b-scission. Using organicbased solvents results in expensive processing, recycling issues, and

the production of deleterious byproducts, which make large-scale

production impractical. Using supercritical carbon dioxide (scCO2)

as a solvent in batch processing eliminates recycling and byproduct

issues but involves complex processing. Furthermore, as reported

by Liu et al. [51], at comparable 0.3e0.4 wt% grafting levels the

synthesis of PP-g-MA by batch, scCO2-assisted solid-state grafting

at 130 C led to greater, rather than suppressed MW reduction, as

compared to melt extrusion.

Supercritical CO2-assisted reactive extrusion has also been

studied for suppressing MW reduction of PP-g-MA. In 2003,

Dorscht and Tzoganakis [52] synthesized PP-g-MA by reactive

extrusion using a 190 C process temperature with and without

scCO2 and employed melt flow index (MFI) and melt flow rate as

indications of MW. They showed that while scCO2-assisted reactive

extrusion and conventional reactive extrusion were equally effective in grafting MA to PP, the use of scCO2 did not suppress chain

scission, likely because of the use of 190 C as process temperature.

In 2010, Cao et al. [54] compared the effect of scCO2-assisted

reactive extrusion at 160 C to that of conventional reactive

extrusion at 190 C on the production of PP-g-MA. They characterized intrinsic viscosity ([h]) of three pairs of samples made

at different MA feed levels, yielding grafting levels of 0.6e0.8,

0.95e1.05, and 1.2 wt% MA in the three pairs. The highest [h] values

were obtained in the sample pair with intermediate 0.95e1.05 wt%

MA composition, indicating that there is not a simple monotonic

relationship between MA grafting level and MW for PP-g-MA made

by reactive extrusion. In each sample pair, the PP-g-MA made with

scCO2 had a slightly higher [h] and thus slightly higher viscosityaverage MW (Mv). (Cao et al. [54] did not report [h] of the starting neat PP.) Using literature MarkeHouwink parameters [66,67],

one can estimate that samples made with scCO2 had Mw values that

were w12% (0.6e0.8 wt% MA grafting), w6% (0.95e1.05 wt% MA

grafting), and w15% (1.2 wt% MA grafting) higher than those

resulting from samples made without scCO2. Although the use of

scCO2 and a 30 C reduction in reactive extrusion temperature led

to suppression of MW reduction (at similar MA graft levels), the

suppression was small in magnitude.

Another approach to suppress MW reduction has involved solidstate functionalization without solvent and at yet lower temperatures. In 2005, Qiu and Hirotsu [55] reported the synthesis of PP-gMA by ball milling, a process commonly used in the powder metallurgy industry but relatively little used in the plastics industry.

Ball milling of polymers is a batch process that typically requires

2e10 h of processing time during which materials in hardened vials

are exposed to high forces from the impact of multiple steel ball

bearings resulting from vial agitation [55,68,69]. Ball or mechanical

milling is a harsh process that leads to chain scission and major MW

reduction (as much as 90% or more) as well as cross-linking for neat

polymers such as polystyrene, polyolefins, polyisoprene and

poly(methyl methacrylate) [55,68,69]. Qiu and Hirotsu measured

the temperature of the polymer during milling (using a thermometer at the beginning of pause steps in the course of a typically

2e10 h process time) and reported it to be 75e85 C, much lower

than other methods used to produce PP-g-MA. At some milling

conditions and feed levels of benzoyl peroxide (the radical initiator)

and MA, they reported that the PP-g-MA was “intensively” [55]

4145

cross-linked. Nevertheless, at other conditions, they suppressed

MW reduction by using ball milling instead of melt processing

at 190 C. They made PP-g-MA at w0.9 wt% MA graft level with

melt-flow index (MFI) ¼ 56 g/10 min by melt processing and

MFI ¼ 18e22 g/10 min by ball milling. At 0.6e0.7 wt% MA graft

level, they obtained PP-g-MA with MFI ¼ 20 g/10 min by melt

processing and MFI ¼ 13 g/10 min by ball milling [55].

Using correlations between PP MW characterization from highT GPC and MFI, [70,71], the reduction in Mw accompanying ball

milling and melt processing may be estimated. The neat PP before

processing had MFI ¼ 1.0 g/10 min, [52], which leads to an estimated Mw ¼ w520,000 g/mol. For the PP-g-MA with w0.9 wt% MA,

the reductions in Mw are w57 and w69% for the milled and melt

processed samples, respectively. For the PP-g-MA with 0.6e0.7 wt%

MA, the reductions in Mw are w53 and w59% for the milled and

melt processed samples, respectively. Although MW reduction was

suppressed by ball milling, the effect was small and similar to that

achieved by Cao et al. [54] with scCO2-assisted reactive extrusion.

Along with the greater than 50% reduction in Mw accompanying PPg-MA synthesis, the batch nature, long process time, and harshness

make ball milling less than ideal for commercial application.

3. Experimental

3.1. Materials

Polypropylene (Total Petrochemicals; MFI ¼ 2.0 g/10 min; ASTM

standard D-1238 at 230 C/2160 g load; reported by the supplier)

was used as received. Azobisisobutyronitrile (AIBN) and MA

were used as received (SigmaAldrich). A phenolic antioxidant,

Songnox 6260 (Songwon), was used as received in samples made

for rheological characterization. Xylene, dodecynl succinic anhydride (DSA), ammonium hydroxide (28% w/w aqueous solution),

and 1-pyrenemethylamine hydrochloride were used for characterizing MA grafting levels and reactivity of the PP-g-MA and were

used as received (SigmaAldrich). 1-pyrenemethylamine (PyrMeNH2) was synthesized by stirring 1-pyrenemethylamine hydrochloride and ammonium hydroxide in xylene solution for

several hours at room temperature, allowing for migration of hydrochloric acid into the aqueous phase and Pyr-MeNH2 into the

xylene phase; separation was by decantation.

3.2. Synthesis of PP-g-MA with SSSP

Dry mixed samples of PP, MA, and AIBN were pulverized using a

relatively harsh screw design [53] at 200 rpm screw speed and

100 g/h feed rate. The pulverizer was a pilot-plant/research scale

Berstoff twin-screw extruder (screw diameter ¼ 25 mm, length/

diameter ¼ 26.5) modified with a cooling system (a Budzar Industries WC-3 chiller at 6 C); the same apparatus was used in

previous SSSP studies [50,56e64]. Samples of PP-g-MA were prepared by SSSP using 4.0 wt% MA and 0.5, 1.0, or 1.5 wt% AIBN. A

control was prepared by SSSP with 1.0 wt % AIBN but without MA. A

PP-g-MA sample with feed composition of 4.0 wt% MA and 1.5 wt%

AIBN was also prepared by melt mixing for 10 min at 200 C in an

Atlas Electronic Devices MiniMAX molder (cup-and-rotor mixer) at

maximum rotor speed and with three steel balls in the cup to

provide chaotic mixing [72]. Table 1 shows sample composition and

process methods. In addition to the samples in Table 1, a sample

was made with 1.0 wt% benzoyl peroxide (BPO; SigmaAldrich) in PP

by SSSP using the same process conditions as for PP/AIBN; this

sample was prepared in order to compare the effect of undecomposed AIBN vs. BPO on the MW degradation of SSSP products

during post-SSSP melt processing.

4146

M.F. Diop, J.M. Torkelson / Polymer 54 (2013) 4143e4154

3.6. Demonstration of reactivity of PP-g-MA with Pyr-MeNH2

Table 1

Variables for Sample Composition and Processing Method.

Sample

MA added

(wt%)

AIBN added

(wt%)

Processing method

Neat PP pellet

(as received)

Neat PP (after SSSP)

PP/MA

e

e

e

e

1.0

e

e

PP/AIBN

PP-g-MA/1

PP-g-MA/2

PP-g-MA/3

PP-g-MA/3 MM

e

4.0

4.0

4.0

4.0

1.0

0.5

1.0

1.5

1.5

SSSP

Dry mixing of

component powders

SSSP

SSSP

SSSP

SSSP

Melt mixing

3.3. Rheological measurements

Neat PP and PP-g-MA samples were used without purification

but with 0.5 wt% Songnox 6260 added to each sample to prevent

thermal degradation. Samples were compression molded into discs

devoid of bubbles. Oscillatory shear rheology data were collected at

180 C, with 10% strain over a frequency range of 0.01e100 rad/s

(measuring from high to low frequency), using a strain-controlled

Rheometrics Scientific ARES rheometer equipped with 25 mm

parallel plates.

3.4. Physical and mechanical properties

Properties were measured for neat PP and SSSP output (PP-gMA) without purification. A Mettler Toledo differential scanning

calorimeter (DSC 822e) was used for thermal analysis. Samples

were heated at 40 C/min to 200 C, held at 200 C for 5 min, cooled

at 40 C/min to 40 C, held at 40 C for 3 min, heated at 10 C/min to

200 C, held at 200 C for 5 min, and cooled at 10 C/min to 40 C.

The crystallinity was determined from the final cooling step.

Both peak and endpoint temperatures of the melting endotherm

(10 C/min) were reported.

Films with w0.5 mm thickness were prepared by pressing in a

PHI hot press at 200 C for 5 min and then rapidly cooling in a PHI

cold press at 16 C for 15 min. Tensile specimens were prepared

according to ASTM D1708; dumbbell-shaped specimens were cut

from films using a Dewes-Gumbs die. An MTS Sintech 20/G (100 kN

load cell; crosshead speed ¼ 5 cm/min) was used to obtain Young’s

modulus and yield strength values at room temperature.

3.5. Quantification of MA grafting

For this characterization, PP-g-MA samples made by SSSP or

melt mixing were purified to remove any unreacted MA by dissolution in boiling xylene followed by precipitation with methanol.

The samples were dried in a vacuum oven at 70 C.

In order to create a calibration curve, DSA/PP blends were prepared by melt processing at 200 C in a MiniMAX molder for 10 min

and at maximum rotor speed with three steel balls in the cup in

order to provide chaotic mixing [72]. Blend products were

compression molded into thin films (w0.3 mm thick) for Fourier

transform infrared (FTIR) spectroscopy. Dodecenyl succinic anhydride was chosen because of its structural similarity to PP-g-MA.

For each blend, three sets of FTIR data were collected with 64

scans and 4 cm1 resolution. Purified PP-g-MA samples were

compression molded into thin films (w0.3 mm thick) and tested

under the same conditions as DSA/PP blends. For PP/MA (prepared

with 1 wt% MA powder dry mixed with PP), the FTIR spectrum

was collected using a disc prepared from the sample powder and

potassium bromide.

The reactivity of purified PP-g-MA was verified by reaction with

Pyr-MeNH2 [73]. In order to achieve this imidization reaction,

50 g/L PP-g-MA samples were dissolved in 0.30 g/L solutions of PyrMeNH2 in xylene. Solutions were held at 100 C for 2 h, after which

PP-g-MA was precipitated in methanol. To remove unreacted PyrMeNH2, samples were purified six times by dissolution in boiling

xylene followed by precipitation in methanol. Pyrene label fluorescence was measured with a Photon Technology International

fluorimeter (lexc ¼ 344 nm).

4. Results and discussion

4.1. Rationale for using AIBN as radical initiator for SSSP synthesis

of PP-g-MA

The radical initiator AIBN was selected for SSSP-based synthesis

of PP-g-MA for a few reasons. It has a half-life of 1 h at 85 C [74,75].

In contrast, dicumyl peroxide, which is commonly used for PP

functionalization by melt processing, has a half-life of 1 h at 132 C

[74]. Thus, we expect AIBN to lead to the formation of more radicals

under the relatively low temperature conditions accompanying

SSSP processing [76]. Also, AIBN radicals do not have the tendency

to participate in chain transfer to PP to any significant extent [77].

This is particularly important when we consider the effect of undecomposed AIBN in PP-g-MA during post-SSSP melt processing at

elevated temperature (to make a product). Besides the fact that

almost all of the AIBN would have decomposed and its radicals lost

(as a result of their termination reactions with each other and

subsequent production of inert molecules [78]) before the PP melts,

any radicals remaining in the system would be unable to cause the

formation of PP macroradicals which could undergo b-scission and

MW reduction. Thus, the presence of undecomposed AIBN in our

samples does not raise any concern associated with AIBN radical

chemistry during post-SSSP melt processing of PP-g-MA. Unlike

AIBN, BPO, which has a half-life of 1 h at 91 C [74], decomposes to

form radicals that undergo significant levels of chain transfer to PP.

For this reason, BPO is less suitable for effective suppression of MW

reduction during PP functionalization via SSSP because of its tendency to cause additional MW reduction during post-SSSP melt

processing.

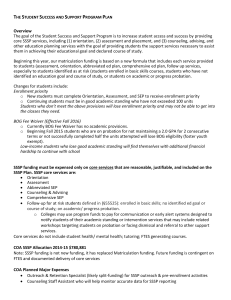

Fig. 1 compares the magnitude of complex viscosity (jh*j) as a

function of frequency for neat PP pellets (as received) and neat PP,

PP/AIBN (with 1.0 wt% AIBN), and PP/BPO (with 1.0 wt% BPO) after

SSSP. Values of zero shear rate viscosity (ho) were determined from

jh*j based on the Cox-Merz rule, which relates linear viscoelastic

properties to steady shear viscosity [79], and application of the

Cross model [80]. Assuming that ho scales with Mw to the 3.4 power

[70,71,81e83], we can use rheology data to characterize the effect

of processing on Mw. Neat PP after SSSP had ho that was 10% less

than that of neat PP pellets (18,200 vs. 20,400 Pa$s), indicating a 3%

reduction in Mw; PP/AIBN had an ho ¼ 14,000 Pa$s, indicating a 10%

reduction in Mw relative to neat PP pellets. The slight difference in

Mw reduction for neat PP after SSSP and PP/AIBN occurs because the

presence of AIBN in PP during SSSP results in an increase in specific

work (the amount of work done per unit mass of material during

SSSP) and thus a slight increase in Mw reduction [56].

In contrast to PP/AIBN, PP/BPO showed a factor of w20 reduction in ho relative to neat PP pellets and thus a major reduction in

Mw (w60%). Because the average residence time in the pulverizer is

on the order of several minutes, only a minority of the BPO would

have decomposed during SSSP, leaving the remaining BPO to

decompose during the melting step used to compression mold the

PP/BPO into a disc for rheology studies. As compared to AIBN

100000

4147

0.8

Neat PP pellet

Neat PP (a er SSSP)

PP/AIBN

0.6

PP/BPO

10000

Absorbance

Magnitude of Complex Viscosity (Pa.s)

M.F. Diop, J.M. Torkelson / Polymer 54 (2013) 4143e4154

1000

Neat PP

3/97 wt% DSA/PP

0.4

0.2

100

0.01

0.1

1

10

Frequency (rad/s)

100

0.0

2000

Fig. 1. Magnitude of complex viscosity as a function of frequency for as received neat

PP pellet (,), neat PP after SSSP (A), PP/AIBN (a sample of 1 wt% AIBN pulverized with

PP under the same conditions as PP-g-MA samples) (), and PP/BPO (a sample of 1 wt%

BPO pulverized with PP under the same conditions as PP-g-MA samples) (B). Data

were collected at 180 C.

radicals, BPO radicals have a much higher propensity for chain

transfer with PP. [77]. Thus, during high-temperature processing

(post-SSSP), which will cause further BPO decomposition, there is a

danger of significant chain transfer between BPO radicals and PP;

this will result in PP macroradical formation and subsequent MW

reduction by b-scission [45e50]. In order to suppress MW reduction for final application, it is essential to use a radical initiator that

does not lead to significant b-scission during post-SSSP high-temperature melt processing. This requirement is met by AIBN.

4.2. Quantitative characterization of MA grafting levels

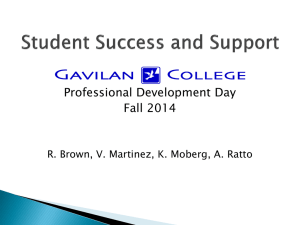

Table 2 shows the locations of peaks associated with three

unique cyclic anhydride absorptions in the 1900e1700 cm1

infrared region [84]. There is no significant absorbance from PP in

this region, as shown in Fig. 2 by a comparison of FTIR spectra of a

3/97 wt% DSA/PP blend and neat PP. A peak at 1170 cm1 is used for

normalization (absorbance of 1.00) of each sample spectrum. This

peak is specific to PP and absent for MA. For all spectral analyses,

the data between 1900 and 1650 cm1 and between 1240 and

1070 cm1 were deconvoluted into component peaks using a Lorentzian function. This yielded accurate peak intensities while accounting for peak overlaps and inconsistent baselines between

spectra. A calibration curve based on DSA was determined using the

analysis described above:

½Anhydride ¼ 0:96ðI1790 =I1170 Þ þ 7:87ðI1713 =I1170 Þ

Wavenumber (cm1)

Characteristic bond

1730e1700

C¼O stretch of carboxylic acid of hydrolyzed

anhydride

Asymmetric C]O stretch (strongest peak)

Symmetric C]O stretch

1800e1775

1870e1845

1600

Fig. 2. FTIR spectra of a blend of 3/97 wt% DSA/PP (solid curve) and neat PP (dashed

curve). The inserted molecular structure is that of dodecynl succinic anhydride (DSA).

where the anhydride concentration is in weight percent and I1790,

I1713, and I1170 are peak intensities at 1790, 1713, and 1170 cm1,

respectively.

Graft levels of PP-g-MA made by SSSP were quantified using

Eq. (1); see Table 3. To verify that all free MA molecules had been

removed by purification, we inspected FTIR spectra for a peak

located between 710 and 690 cm1. Absorbance in that region is as

a result of out-of-plane ¼CeH bond stretch associated with free MA

(grafted MA does not show this absorbance) [84]. The presence of

such a peak in a mixed sample of 1/99 wt% MA/PP (containing free

rather than grafted MA) and its absence in all of our purified PP-gMA samples indicates that our purification led to essentially complete removal of free MA (See Fig. 3.). While PP-g-MA prepared by

SSSP resulted in 0.3e0.5 wt% grafting levels (more specifically,

0.27 0.04 to 0.47 0.04 wt% MA), PP-g-MA/3 MM (see Table 3)

prepared by melt processing resulted in no significant grafting of

MA, consistent with discussion in Section 4.1 above. A comparison

of FTIR spectra for neat PP, PP-g-MA/3, and PP-g-MA/3 MM is

shown in Fig. 4, which demonstrates that PP-g-MA/3 MM has no

discernable level of MA grafting.

Table 3

Characterization of MA grafting levels, Mw reduction from ho data, crystallinity, and

tensile properties for neat PP and PP-g-MA samples made via SSSP.

Sample

MA grafting Percent Mw Crystallinity Young’s

modulus

levela (wt%) reductionb (%)

(%)

(MPa)

Yield

strength

(MPa)

Neat PP pellets

(as received)

Neat PP

(after SSSP)

PP-g-MA/1

PP-g-MA/2

PP-g-MA/3

e

(1)

Table 2

Characteristic peaks associated with cyclic anhydride absorption in the infrared

region.

1800

Wavenumber (cm-1)

47

1340 20

38 1

3

48

1400 90

37 2

0.27 0.04 16

0.32 0.05 20

0.47 0.04 25

47

48

48

1300 70 34 1

1300 100 33 1

1200 30 34 1

e

e

a

MA grafting levels expressed in wt% can be converted into units of meq (i.e., the

number of moles of MA in 1 g of PP-g-MA multiplied by 106) by simple stoichiometric calculations (e.g., 0.3 wt% MA is equivalent to w31 meq).

b

Percent reduction in Mw relative to neat PP pellets (as received) was calculated

using the assumption that ho scales with Mw to the 3.4 power.

4148

M.F. Diop, J.M. Torkelson / Polymer 54 (2013) 4143e4154

0.12

oligomer grafts in some PP-g-MA syntheses at temperatures below

160 C [4,5,55]. Because PP-g-MA synthesis by SSSP occurs at low

temperature and based on our observation of a peak at 1780 cm1,

it is possible that PP-g-MA prepared by SSSP contains some MA

oligomers grafted onto PP.

1/99 wt% MA/PP

PP-g-MA/3

Absorbance

PP-g-MA/3MM

0.08

Neat PP

4.3. Molecular weight characterization and molecular weight

reduction in PP-g-MA

0.04

0.00

750

725

700

Wavenumber

675

650

(cm -1)

Fig. 3. FTIR spectra of 1/99 wt% MA/PP (bold curve), PP-g-MA/3 (dotted curve), PP-gMA/3 MM (short-dashed curve), and neat PP (long-dashed curve). The comparison

shows no absorbance associated with free anhydride moieties in PP-g-MA/3, PP-g-MA/

3 MM, or neat PP. A very strong absorbance due to free anhydride moieties is observed

for the sample of 1/99 wt% MA/PP as expected.

In Fig. 4, the FTIR spectrum for PP-g-MA/3 exhibits two peaks

at w1790 and w1780 cm1. The peak at w1780 cm1 may be from

oligomeric chains of MA grafted to PP [48]. However, homopolymerization of MA during PP functionalization is a controversial

issue. The argument against MA homopolymerization during hightemperature functionalization of PP is based on the fact that the

ceiling temperature for homopolymerization of MA in benzene is

160 C [85]. Temperatures above the ceiling temperature favor

depolymerization over polymerization. Some studies [42,86,87]

have reported evidence of MA oligomer grafts to PP by melt functionalization, which was ascribed to effects of local MA concentration on ceiling temperature. There is also evidence for MA

High-temperature GPC data were obtained for neat PP pellets

(as received) and PP-g-MA/3 [88]. Samples were dissolved in trichlorobenzene and tested at 145 C; a triple detection method was

used [89]. The MW values from these samples, as well as those

reported for PP-g-MA synthesis via reactive extrusion by Shi et al.

[8], are presented in Table 4.

Both PP-g-MA/3 (made by SSSP) and PP-g-MA/RE (made by

reactive extrusion) [8] have MA grafting levels of w0.5 wt%. Based

on the 0.5 wt% grafting level and 32,000 g/mol number-average

MW (Mn) value reported for PP-g-MA/RE, on average one to two

MA units are incorporated in each PP chain. This result is consistent

with the idea that the extent of b-scission is high during reactive

extrusion and that most of the radicals that participate in MA

grafting, and thus the MA functional groups themselves, are located

at PP chain ends. In contrast, the 0.5 wt% grafting level for PP-g-MA/

3 with Mn ¼ 89,000 g/mol indicates that four to five MA units are

incorporated in each PP chain. Unlike the sample made by reactive

extrusion, the PP-g-MA made by SSSP has the MA functional groups

distributed along the chain length rather than being located predominantly at chain ends. This is evident from the discussion

below.

Using Mn values, the average number of scission events per

chain can be determined with the following analysis. Starting with

one chain, one scission event will result in two chains, two scission

events will result in three chains, etc. This relationship between the

number of scission events and the number of chains results in Eq.

(2), which relates the average number of scission events per chain,

zc, to change in Mn:

i

h

zc ¼ Mn;o =Mn;f 1

(2)

where Mn,o is the initial Mn, and Mn,f is the final Mn after scission.

Based on Eq. (2), zc ¼ 0.090 scission events per chain for PP-g-MA/3,

i.e., for every 100 original PP chains, there were 9 scission events. If

each scission event during SSSP resulted in a radical at each of two

chain ends that was capable of adding an MA functional group, then

18 MA functional groups could be added per 109 PP chains present

after scission. However, given the w0.5 wt% MA grafting level,

these 109 chains would contain w400e500 MA units, a factor of

w25 higher than the number of chain ends created by scission.

While it is possible that some chain-end radicals may result in

incorporation of more than one MA functional group, the low

Table 4

High-T GPC Characterization of Mn and Mw before and after Functionalization via

SSSP and Reactive Extrusion [8].

Fig. 4. FTIR spectra of PP-g-MA/3 (bold curve), PP-g-MA/3 MM (dotted curve), and

neat PP (dashed curve). The comparison shows no clear absorbance associated with

anhydride groups in PP-g-MA/3 MM.

Sample

Mn (g/mol)

PP-g-MA synthesis via

Neat PP pellets

(as received)

PP-g-MA/3

PP-g-MA synthesis via

Neat PP (as received)

PP-g-MA/RE

SSSP

97,000

Percent Mn

reduction (%)

Mw (g/mol)

Percent Mw

reduction (%)

e

397,000

e

268,000

32

273,000

80,000

e

71

89,000

8

Reactive Extrusion [8]

65,000

e

32,000

51

propensity of MA to undergo homopolymerization [4,5,55] and the

low MA concentration used in the SSSP process argue strongly

against the notion that most MA functional groups are present as

homopolymer grafted onto PP chain ends. Instead, a high level of

the MA functional groups must be incorporated at locations along

the chain length other than chain ends [90].

Equation (2) also allows us to compare the frequency of scission

events per chain for PP-g-MA synthesis by SSSP (zc ¼ 0.090) with

that by reactive extrusion (zc ¼ 1.03). Given that the Mn,o values

were different for PP-g-MA/3 and PP-g-MA/RE, an appropriate

comparison requires that we determine the frequency of scission

events per repeat unit in each system. Taking into account that the

initial number-average degree of polymerization was 2205 for PPg-MA/3 and 1477 for PP-g-MA/RE, then one scission event occurs

per 24,500 repeat units with PP-g-MA/3 and per 1430 repeat units

in PP-g-MA/RE. Thus, with the synthesis of PP-g-MA with 0.5 wt%

MA graft level, SSSP suppresses the frequency of chain scission per

repeat unit by w94% relative to reactive extrusion.

Table 4 also shows the percent reduction in Mw for PP-g-MA/3

and PP-g-MA/RE. These reductions in Mw (32% for PP-g-MA/3 and

71% for PP-g-MA/RE) are significantly larger than the reductions in

Mn (8% for PP-g-MA/3 and 51% for PP-g-MA/RE). This is expected

because the probability that a chain undergoes b-scission is proportional to the number of repeat units in the chain. Hence, a chain

with five times the repeat units of a shorter chain with have five

times the frequency of scission events of the shorter chain, and Mw

will thereby suffer a greater percentage reduction than Mn.

Nevertheless, synthesis of PP-g-MA by SSSP results in much smaller

reductions in Mn and Mw (based on high-T GPC characterization)

relative to those achieved by reactive extrusion. (If we had

employed a neat PP sample with Mn identical to the 65,000 g/mol

sample used by Shi et al. [8], then SSSP would have led to only a 6%

reduction in Mn, from 65,000 to 61,300 g/mol.)

Most previous studies of MW reduction accompanying PP-g-MA

synthesis via post-polymerization did not report any Mn values nor

Mw values based on high-T GPC; instead, they reported results that

may be interpreted in terms of Mw based on viscosity or MFI

characterization. In order to make a fair comparison between

studies as well as to compare the effects of MA graft level in our

own study, we have also used rheology to characterize the apparent

reduction in Mw in our three PP-g-MA samples made by SSSP. Fig. 5

shows jh*j as a function of frequency for PP-g-MA and control

samples. Values of ho were calculated by employing the Cox-Merz

rule [79] and the Cross model [80]. (It is worth noting that

neither the control nor PP-g-MA samples show any signs of chain

branching [91].) We characterized the effect of SSSP processing and

MA functionalization on Mw reduction by assuming that ho scales

with the 3.4 power of Mw. [70,71,81e83]. As shown in Table 3,

pulverization of neat PP without MA or AIBN results in w3%

reduction in Mw, confirming that under the conditions utilized in

this work, SSSP alone results in negligible MW reduction. For pulverized PP-g-MA samples, we observe Mw reductions of 16e25% for

0.3 to 0.5 wt% MA grafting levels from rheology. The 25% reduction

in Mw estimated from rheology for PP-g-MA/3 is slightly below the

32% reduction calculated from high-T GPC characterization, indicating approximate agreement between methods. Alternatively,

Mw values can be determined using data reported by Fujiyama et al.

[71] in an hoeMw correlation for PP [71,92]. Percent reductions in

Mw obtained from this correlation agree well with the determinations in Table 3 made by simple application of the 3.4 power law relation to our ho data (see Table 5).

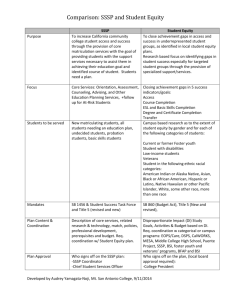

Fig. 6 compares the percent reductions in Mw obtained with PPg-MA syntheses via conventional reactive extrusion [8], scCO2assisted reactive extrusion [54], ball milling [55], and SSSP. In the

case of the non-SSSP-based syntheses, the Mw values are reduced

Magnitude of Complex Viscosity (Pa.s)

M.F. Diop, J.M. Torkelson / Polymer 54 (2013) 4143e4154

4149

100000

10000

Neat PP pellet

1000

Neat PP (a er SSSP)

PP-g-MA/1

PP-g-MA/2

PP-g-MA/3

100

0.01

0.1

1

10

Frequency (rad/s)

100

Fig. 5. Magnitude of complex viscosity as a function of frequency for as received neat

PP pellet (,), neat PP pulverized (A), PP-g-MA/1 (D), PP-g-MA/2 (), and PP-g-MA/3

(B). Data were collected at 180 C.

by more than 50% and in some cases by more than 70% at MA graft

levels ranging from 0.2 to 0.9 wt%. At most there is only a weak

increase in Mw reduction with increasing MA graft level. In contrast,

the PP-g-MA made by SSSP with 0.3e0.5 wt% MA graft levels

resulted in much smaller, 16e25% reductions in Mw based on zero

shear rate viscosity data; based on GPC characterization of the

sample with 0.5 wt% MA graft level, Mw was reduced by a relatively

modest 32%. While the results from the PP-g-MA samples made by

SSSP suggest that Mw reduction increases with MA graft level, they

also strongly demonstrate that the level of reduction in Mw

accompanying SSSP is much smaller in comparison with other

methods of PP-g-MA synthesis reported in the literature. Thus,

whether the comparison is done by frequency of chain scission

events per repeat unit, percent reduction in Mn, or percent reduction in Mw, the PP-g-MA synthesized by SSSP experiences strong

suppression of chain scission and MW reduction relative to similar

materials synthesized by other post-polymerization methods

described in the literature.

4.4. Reactivity of PP-g-MA with Pyr-MeNH2

Polymers grafted with MA are used commercially in reactive

compatibilization in which the MA unit reacts to form a covalent

bond with a functional group, e.g., an amine, on the blend partner

chain, such as polyamide. Here, we demonstrate the reactivity of

PP-g-MA made by SSSP with a model system involving Pyr-MeNH2.

This system was selected because trace levels of pyrenyl chromophores covalently attached via a condensation-type linkage to

Table 5

Mw Reductions for Samples made by SSSP as Determined from Data Presented by

Fujiyama et al. [71,92].

Sample

MA grafting

level (wt%)

ho (Pa s)

Mw (g/mol)

Percent Mw

reduction (%)

Neat PP pellets

(as received)

Neat PP (after SSSP)

PP-g-MA/1

PP-g-MA/2

PP-g-MA/3

e

20,400

456,000

e

e

0.27 0.04

0.32 0.05

0.47 0.04

18,200

11,700

8500

7700

444,000

398,000

359,000

344,000

3

13

21

24

4150

M.F. Diop, J.M. Torkelson / Polymer 54 (2013) 4143e4154

Percent Reduction in Mw

80

are related to how the moieties attached to the pyrenyl unit modify

its photophysical response [95,96]. In any case, the fluorescence of

PP-g-MA/3 after reaction with Pyr-MeNH2 (and purification) proves

that PP-g-MA made by SSSP can be used for reactive compatibilization. A control study was done on neat PP using the same reaction

and purification protocol as for PP-g-MA/3 and resulted in no

fluorescence.

70

60

50

40

4.5. Physical and mechanical properties

30

Table 3 shows the percent crystallinity for PP-g-MA samples

made by SSSP. Percent crystallinity (ccrys) was determined using

Eq. (3):

20

10

0.2 0.4 0.6 0.8

1

MA grafting level (wt%)

Fig. 6. Comparison of percent reduction in Mw as a function of MA grafting level for PPg-MA synthesis via reactive extrusion (,) [8], sceCO2eassisted reactive extrusion (✕)

[54], ball milling (>) [55], SSSP e rheology data (C), and SSSP e high-T GPC data (:).

polymer chains are known to be highly fluorescent [93,94] in dilute

solution and allow for confirmation of reactivity.

Fig. 7a shows the fluorescence spectrum of a solution of 0.3 g/L

Pyr-MeNH2 in xylene. Fig. 7b show the fluorescence spectrum of a

2 g/L PP-g-MA/3 solution in xylene after reaction with Pyr-MeNH2.

The latter spectrum was collected after the reaction product was

purified by six dissolution/precipitation cycles to remove any

unreacted Pyr-MeNH2. Under these solution conditions, the pyrenyl

chromophore emission is associated with monomer fluorescence;

within error, excimer fluorescence (with a peak intensity at 480 nm

and emission extending above 550 nm) [93,94] is absent. This

suggests that any MA oligomers that may be grafted to the PP-g-MA

do not react with more than one Pyr-MeNH2 molecule, because the

presence of two or more pyrenyl dyes on the oligomers would

likely lead to excimer fluorescence (Excimer fluorescence results

when an excited-state dimer produced from interaction of an

excited-state pyrenyl unit with a neighboring pyrenyl unit returns

to the ground state via radiation of a photon.) Shifts in pyrenyl

emission peak wavelength and structure similar to those in Fig. 7

after functionalization have been observed in other studies and

1.00

a

0.75

0.50

0.25

0.00

360

(3)

where DHf is the sample enthalpy of fusion and DHfo is enthalpy of

fusion for 100% crystalline PP (DHfo ¼ 207.1 J/g [97]). For PP-g-MA

samples synthesized via SSSP, 47e48% crystallinity levels were

achieved independent of graft level for the 0.3e0.5 wt% MA graft

levels (see Table 3) and unchanged from the crystallinity of the neat

PP from which the PP-g-MA samples were synthesized. Additionally, melt temperatures of 165e167 C (peak values) and 171e174 C

(endpoints) were observed for neat PP (after SSSP) and all PP-g-MA

samples. These values are identical, within experimental error, to

those for the neat PP (as received) from which the PP-g-MA samples were made. These results indicate that physical properties

related to crystallinity of neat PP should be retained after MA

functionalization by SSSP. It is interesting to note that in a very

recent publication, Zhang et al. [41] described the synthesis of high

MW PP-g-MA from copolymers of propylene and p-(3-butenyl)

toluene. For MA graft levels of 0.3e0.5 wt% (as determined from

FTIR) they observed sample crystallinities of 21e39%, significantly

below those for PP-g-MA synthesized by SSSP; such a reduction of

PP crystallinity may compromise mechanical and physical properties significantly.

Table 3 also shows Young’s modulus (E) and yield strength (sy)

values of neat PP before and after SSSP and PP-g-MA samples.

Within error, SSSP of neat PP had no effect on E and sy values,

consistent with the fact that the MW and crystallinity of neat PP

before and after SSSP were identical or nearly so. Relative to neat PP,

Normalized Intensity

Normalized Intensity

1.00

ccrys ¼ DHf =DHfo 100%

b

0.75

0.50

0.25

0.00

385

410

435

Wavelength (nm)

460

360

385

410

435

Wavelength (nm)

460

Fig. 7. Fluorescence spectra of (a) 0.3 g/L solution of Pyr-MeNH2 in xylene at 100 C; (b) 2 g/L solution PP-g-MA/3 in xylene at 100 C after first being reacted with Pyr-MeNH2 and

then purified six times by dissolution and precipitation to remove unreacted Pyr-MeNH2. (Both spectra have had emission intensity normalized to unity at the peak emission

wavelength.)

M.F. Diop, J.M. Torkelson / Polymer 54 (2013) 4143e4154

the three PP-g-MA samples exhibited w10% decreases in sy; only

PP-g-MA/3 with the highest MA grafting level (w0.5 wt%) and

largest Mw reduction (w25% by rheology) exhibited any modulus

reduction, w10% in this case. Thus, the tensile properties of PP-gMA made by SSSP are at most only slightly degraded relative to

those of the neat PP from which they were synthesized. This is

expected based on the 0.3e0.5 wt% MA incorporation and the

limited MW reduction in the PP-g-MA samples.

4.6. Proposed mechanism of PP-g-MA synthesis via SSSP using AIBN

as radical initiator

The mechanism for functionalization begins with the decomposition of AIBN into radicals, according to Scheme 2. Azo-type

initiators form radicals that do not participate significantly in

chain transfer but are excellent at addition reactions [77]. Thus, we

expect that radicals from AIBN will add onto MA molecules to form

MA-complex radicals. An MA-complex radical can then abstract

hydrogen from a tertiary carbon on a PP chain to form a PP macroradical. The macroradical can either add an MA unit to form PP-gMA (Scheme 2, step [4]) or undergo b-scission, resulting in MW

reduction. The dominant activity of the macroradical is MA grafting

owing to the low temperature. Thus, by using SSSP we benefit from

radical chemistries that encourage MA grafting and strongly suppress b-scission. Once MA is grafted onto PP, the radical on the MA

molecule can either abstract a tertiary H atom from a PP chain

(Scheme 2, step [5]) or add other MA molecules resulting in MA

oligomers grafted onto PP; see Scheme 3, step [1]. The radical on

4151

the MA oligomer can be stabilized after it abstracts an H atom from

a PP chain. Heinen et al. [98] showed that for PP functionalization

with MA at 170 C, grafting of MA oligomers onto PP was highly

unlikely because radicals that may result in oligomer formation are

more likely to abstract a tertiary H atom from PP to form a PP

macroradical. However, for PP-g-MA made by SSSP, the FTIR spectra

(Fig. 4) strongly suggest that some MA oligomers are grafted onto

PP. Thus, by functionalizing PP via SSSP at low temperature, we

obtain a different type of radical chemistry that encourages some

MA homopolymerization. It is worth noting that the presence of

grafted MA oligomers is not believed to affect the utility of PP-g-MA

in commercial applications [99e101].

In Scheme 4, we describe another potential reaction between

the MA-complex radical (produced in Scheme 2, step [2]) and a PP

macroradical to produce PP functionalized with the MA-complex

radical. However, there is no indication of the nitrile (eCN) bond

stretch in FTIR spectra (at 2260e2240 cm1) of the PP-g-MA

samples; this suggests that the reaction occurs to at most a very

small extent during MA functionalization of PP by SSSP. It is also

important to note that because PP-g-MA synthesis by SSSP is not

occurring in an inert environment, it is possible to achieve some

degree of radical stabilization by atmospheric oxygen (not shown in

schemes) [102].

4.7. Implications and future work

In this proof-of-principle study, we have shown with a pilotplant/research scale pulverizer that SSSP can produce PP-g-MA at

Scheme 2. Proposed mechanism for MA functionalization using AIBN via SSSP; PP functionalization with a single anhydride molecule.

4152

M.F. Diop, J.M. Torkelson / Polymer 54 (2013) 4143e4154

Scheme 3. Proposed mechanism for MA functionalization using AIBN via SSSP; PP functionalization with MA oligomers.

Scheme 4. Proposed mechanism for MA functionalization using AIBN via SSSP; PP functionalization with an MA-complex radical.

0.5 wt% MA graft level with a greater than 90% suppression of

scission per repeat unit relative to that obtained with reactive melt

extrusion. At 0.5 wt% MA, the grafting efficiency for this PP-g-MA

sample is w13%. In some instances, greater grafting efficiencies

have been reported for PP-g-MA samples with comparable grafting

levels synthesized via reactive extrusion (w17e50%, depending on

initial amounts of MA and the radial initiator [8]). It is important to

note that optimization of the SSSP-based synthesis of PP-g-MA has

not yet been considered for MA graft level, MW reduction, or

output rate. We note that the graft levels associated with PP-g-MA

synthesis by SSSP can be tuned by varying the specific work [56]

that is done on the material during SSSP. In particular, the temperature of the polymer in the pulverizer increases as specific work

increases, and an increase in graft level is thus expected with

increasing specific work. We have demonstrated this with a simple

variation of the experiment in which we synthesized PP-g-MA/3

(using 4 wt% MA and 1.5 wt% AIBN). By increasing the feed rate

by 45%, both the specific work done on the polymer and the MA

graft level increased, the latter from 0.5 to 0.7 wt% (an increase

from w13 to w18% in grafting efficiency). This result indicates that

graft level and grafting efficiency can be tuned substantially by SSSP

processing conditions alone via connection to specific work and

temperature.

However, given that MA is relatively inexpensive and comparable in cost to PP, suppression of MW reduction is more important

than MA grafting efficiency for the application of SSSP in PP-g-MA

synthesis. While we do not necessarily expect that a total suppression of MW reduction will ever be achieved with postpolymerization synthesis of PP-g-MA, the extent to which this

suppression may be tuned by SSSP conditions deserves further

study. Additionally, given that SSSP processing of polyolefins has

been done at Northwestern University at rates exceeding 150 kg/h

with a 60-mm-diameter screw, commercial-scale pulverizer, there

is need for future scale-up studies related to PP-g-MA synthesis.

Simple analysis of the economics of SSSP, including amortized cost

of the equipment, energy, labor, maintenance, and contingencies

(but not including the cost of materials), indicates that SSSP of

polyolefins can be done at a cost of US$ 0.40 per kg using

commercial-scale equipment.

Finally, besides presenting a novel method for overcoming the

challenges arising from post-polymerization synthesis of PP-g-MA

by conventional, melt-state processing, this study has opened the

door to applications of SSSP for a new platform of chemistries (e.g.,

radical chemistries unique to low temperature conditions) that are

not achievable by melt processing. Such unique chemistries

include, but are not limited to, direct functionalization of PP with

organic peroxides. There has been long-standing interest in this

type of functionalization as made clear by Boaen and Hillmyer who

stated in their 2005 review that an “.interesting approach that is

related but could prove to be more efficient is the direct functionalization (of polyolefins) with organic peroxides (i.e., no monomer).” [26] We hypothesize that SSSP can meet the challenge of

direct polar-group functionalization of PP with organic peroxides

alone. Studies are in progress.

5. Conclusion

We have demonstrated a novel solid-state method for postpolymerization synthesis of PP-g-MA which very strongly suppresses b-scission, a radical chemistry that is highly dependent on

temperature, and its deleterious side effect of MW reduction.

Furthermore, we have provided reaction schemes consistent with

the research literature and our experimental results that explain

both the MA grafting to PP and the suppression of chain scission

M.F. Diop, J.M. Torkelson / Polymer 54 (2013) 4143e4154

achieved by SSSP. At the high temperatures utilized with the

common commercial method of PP-g-MA synthesis (i.e., reactive

extrusion), the extent of b-scission is significant and results in

dramatic MW reduction and degradation of properties. For

example, when Shi et al. [8] synthesized PP-g-MA with 0.5 wt% MA

graft level by melt extrusion, there was one scission event per

1430 PP repeat units, resulting in a 51% reduction of Mn (from a

reported 65,000 to 32,000 g/mol) and a 71% reduction in Mw (from

a reported 273,000 to 80,000 g/mol). We have suppressed b-scission by taking advantage of radical chemistries that are present at

the relatively low temperatures associated with SSSP. For example,

when we synthesize PP-g-MA with 0.5 wt% MA graft level, MW

characterization by high-T GPC indicates that there is one scission

event per 24,500 repeat units. Thus, SSSP reduces the probability of

scission per repeat unit by w94% relative to that achieved in

reactive extrusion at a 0.5 wt% MA graft level (The level of scission

that accompanied SSSP led to an 8% reduction in Mn, from 97,000 to

89,000 g/mol, and a 32% reduction in Mw, from 397,000 to

268,000 g/mol.). Another unique facet of this study is the use of

AIBN rather than an organic peroxide as initiator. Unlike radicals

produced from peroxides, radicals produced by AIBN do not

participate in chain transfer to PP at low or high temperature [77],

ensuring that MW reduction can be strongly suppressed during

subsequent melt processing of PP-g-MA into a final product.

Because of the suppressed MW reduction achieved with SSSP,

PP-g-MA exhibits little to no mechanical or physical property

degradation relative to the neat PP from which it is made. The

resulting PP-g-MA is also effective in model condensation-type

reactions and thus will be effective in applications related to

reactive compatibilization. These results indicate that postpolymerization functionalization by SSSP can answer the longstanding challenge of grafting functional groups onto polypropylene in a selective and mild manner [26,103]. Given its

continuous, solventless, and industrially scalable nature, SSSP is

also a candidate to be used commercially for producing PP-g-MA

with strong suppression of chain scission and MW reduction.

Acknowledgments

We acknowledge support from a 3M Graduate Fellowship (to

M.F.D.), the Initiative for Sustainability and Energy at Northwestern

(ISEN), and Northwestern University. This study made use of Central Facilities supported by the MRSEC program of the National

Science Foundation at the Northwestern University Materials

Research Science and Engineering Center. High-T GPC characterization was performed at the Polymer Characterization Lab at the

University of Tennessee.

References

[1] Chung TC. Prog Polym Sci 2002;27:39e85.

[2] Yazdani-Pedram M, Vega H, Quijada R. Polymer 2001;42:4751e8.

[3] Chmela S, Fiedlerova A, Janigova I, Novak I, Borsig E. J Appl Polym Sci

2011;119:2750e8.

[4] Galia A, De Gregorio R, Spadaro G, Scialdone O, Filardo G. Macromolecules

2004;37:4580e9.

[5] Lazar M, Hrckova L, Fiedlerova A, Borsig E, Rätzsch M, Hesse A. Angew

Makromol Chem 1996;243:57e67.

[6] Minoura Y, Ueda M, Mizunuma S, Oba M. J Appl Polym Sci 1969;13:1625e40.

[7] Bettini SHP, Agnelli JAM. J Appl Polym Sci 2002;85:2706e17.

[8] Shi D, Yang J, Yao Z, Wang Y, Huang H, Jing W, et al. Polymer 2001;42:

5549e57.

[9] Ni Q-L, Fan J-Q, Niu H, Dong J-Y. J Appl Polym Sci 2011;121:2512e7.

[10] Zhang R, Zhu Y, Zhang J, Jiang W, Yin J. J Polym Sci Part A Polym Chem

2005;43:5529e34.

[11] Navarre S, Degueil M, Maillard B. Polymer 2001;42:4509e16.

[12] Saule M, Navarre S, Babot O, Maslow W, Vertommen L, Maillard B. Macromolecules 2003;36:7469e76.

[13] Navarre S, Saule M, Maillard B. J Appl Polym Sci 2003;87:699e707.

4153

[14] Saule M, Moine L, Degueil-Castaing M, Maillard B. Macromolecules 2005;38:

77e85.

[15] Boaen NK, Hillmyer MA. Chem Soc Rev 2005;34:267e75.

[16] Boffa LS, Novak BM. Chem Rev 2000;100:1479e93.

[17] Ravasio A, Boggioni L, Tritto I. Macromolecules 2011;44:4180e6.

[18] Bouilhac C, Rünzi T, Mecking S. Macromolecules 2010;43:3589e90.

[19] Zhao P, Shpasser D, Eisen MS. J Polym Sci Part A Polym Chem 2012;50:

523e33.

[20] Opper KL, Markova D, Klapper M, Müllen K, Wagener KB. Macromolecules

2010;43:3690e8.

[21] Kandil U, Chung TC. J Polym Sci Part A Polym Chem 2005;43:1858e72.

[22] Berkefeld A, Mecking S. Angew Chem Int Ed 2008;47:2538e42.

[23] Hong M, Cui L, Liu S, Li Y. Macromolecules 2012;45:5397e402.

[24] Hong M, Liu J-Y, Li B-X, Li Y-S. Macromolecules 2011;44:5659e65.

[25] Lin W, Dong J, Chung TCM. Macromolecules 2008;41:8452e7.

[26] Chung TC, Xu G, Lu Y, Hu Y. Macromolecules 2001;34:8040e50.

[27] Wang ZM, Hong H, Chung TC. Macromolecules 2005;38:8966e70.

[28] Sacchi A, Di Landro L, Pegoraro M, Severini F. Eur Polym J 2004;40:

1705e13.

[29] Abacha N, Fellahi S. Polym Int 2005;54:909e16.

[30] Shi D, Ke Z, Yang J, Gao Y, Wu J, Yin J. Macromolecules 2002;35:8005e12.

[31] Gamstedt EK, Berglund LA, Peijs T. Compos Sci Technol 1999;59:759e68.

[32] Bullions TA, Gillespie RA, Price-O’Brien J, Loos AC. J Appl Polym Sci 2004;92:

3771e83.

[33] Arbelaiz A, Fernandez G, Cantero G, Llano-Ponte R, Valea A, Mondragon I.

Composites Part A 2005;36:1637e44.

[34] Hasegawa N, Okamoto H, Kato M, Usuki A. J Appl Polym Sci 2000;78:1918e22.

[35] Martín Z, Jimenez I, Gomez-Fatou MA, West M, Hitchcock AP. Macromolecules 2011;44:2179e89.

[36] Xu L, Nakajima H, Manias E, Krishnamoorti R. Macromolecules 2009;42:

3795e803.

[37] Polacco G, Stastna J, Biondi D, Zanzotto L. Curr Opin Colloid Interface Sci

2006;11:230e45.

[38] Yeh P-H, Nien Y-H, Chen J-H, Chen W-C, Chen J-S. Polym Eng Sci 2005;45:

1152e8.

[39] Lu B, Chung TC. Macromolecules 1999;32:2525e33.

[40] Lu B, Chung TC. J Polym Sci Part A Polym Chem 2000;38:1337e43.

[41] Zhang M, Colby RH, Milner ST, Chung TCM, Huang T, deGroot W. Macromolecules 2013;46:4313e23.

[42] Guldogan Y, Egri S, Rzaev ZMO, Piskin E. J Appl Polym Sci 2004;92:3675e84.

[43] Moad G. Prog Polym Sci 1999;24:81e142.

[44] Ho RM, Su AC, Wu CH, Chen SI. Polymer 1993;34:3264e9.

[45] Rätzsch M, Arnold M, Borsig E, Bucka H, Reichelt N. Prog Polym Sci 2002;27:

1195e282.

[46] Dickens B. J Polym Sci Polym Chem Ed 1982;20:1169e83.

[47] Hinsken H, Moss S, Pauquet J-R, Zweifel H. Polym Degrad Stab 1991;34:

279e93.

[48] De Roover B, Sclavons M, Carlier V, Devaux J, Legras R, Momtaz A. J Polym Sci

Part A Polym Chem 1995;33:829e42.

[49] Kruse TM, Wong H-W, Broadbelt LJ. Macromolecules 2003;36:9594e607.

[50] Kruse TM, Levine SE, Wong H-W, Duoss E, Lebovitz AH, Torkelson JM, et al.

J Anal Appl Pyrolysis 2005;73:342e54.

[51] Liu T, Hu G-H, Tong G, Zhao L, Cao G, Yuan W. Ind Eng Chem Res 2005;44:

4292e9.

[52] Dorscht BM, Tzoganakis C. J Appl Polym Sci 2003;87:1116e22.

[53] Henry GRP, Drooghaag X, Rousseaux DDJ, Sclavons M, Devaux J, MarchandBrynaert J, et al. J Polym Sci Part A Polym Chem 2008;46:2936e47.

[54] Cao K, Shen Z, Yao Z, Qu B, Pang X, Lu Z, et al. Chem Eng Sci 2010;65:1621e6.

[55] Qiu W, Hirotsu T. Macromol Chem Phys 2005;206:2470e82.

[56] Brunner PJ, Clark JT, Torkelson JM, Wakabayashi K. Polym Eng Sci 2012;52:

1555e64.

[57] Furgiuele N, Lebovitz AH, Khait K, Torkelson JM. Macromolecules 2000;33:

225e8.

[58] Lebovitz AH, Khait K, Torkelson JM. Macromolecules 2002;35:8672e5.

[59] Tao Y, Lebovitz AH, Torkelson JM. Polymer 2005;46:4753e61.

[60] Lebovitz AH, Khait K, Torkelson JM. Macromolecules 2002;35:9716e22.

[61] Masuda J, Torkelson JM. Macromolecules 2008;41:5974e7.

[62] Wakabayashi K, Pierre C, Dikin DA, Ruoff RS, Ramanathan T, Brinson LC, et al.

Macromolecules 2008;41:1905e8.

[63] Wakabayashi K, Brunner PJ, Masuda J, Hewlett SA, Torkelson JM. Polymer

2010;51:5525e31.

[64] Iyer KA, Torkelson JM. Polym Compos. http://dx.doi.org/10.1002/pc.22534.

[65] Jiang X, Drzal LT. J Appl Polym Sci 2012;124:525e35.

[66] Kurata M, Tsunashima Y. In Wiley Database of Polymer Properties. Hoboken,

NJ: Wiley.

[67] The ratio between two Mw values was determined using their respective

intrinsic viscosities ([h]) and the equation [h]1/[h]2 ¼ (Mw,1/Mw,2)a with

a ¼ 0.8 for isotactic PP dissolved in decalin at 135 C. The [h] e Mw relaa

tionship used is [h] ¼ Kw(Mw)a, where Kw ¼ K[Mw/Mn]0.5a( 1) (see Ref. [62]).

[68] Smith AP, Spontak RJ, Ade H. Polym Degrad Stab 2001;72:519e24.

[69] Smith AP, Shay JS, Spontak RJ, Balik CM, Ade H, Smith SD, et al. Polymer

2000;41:6271e83.

[70] Bremner T, Rudin A, Cook DG. J Appl Polym Sci 1990;41:1617e27.

[71] Fujiyama M, Kitajima Y, Inata H. J Appl Polym Sci 2002;84:2128e41.

[72] Maric M, Macosko CW. Polym Eng Sci 2001;41:118e30.

4154

M.F. Diop, J.M. Torkelson / Polymer 54 (2013) 4143e4154

[73] Padwa AR, Sasaki Y, Wolske KA, Macosko CW. J Polym Sci Part A Polym Chem

1995;33:2165e74.

[74] Dixon KW. In: Wiley Database of Polymer Properties. Hoboken, NJ: Wiley.

[75] O’Neil GA, Torkelson JM. Macromolecules 1999;32:411e22.

[76] Under the SSSP conditions utilized for this study, the temperature of material

on a macro-scale within the pulverizer barrel during pulverization was no

higher than 50 C. As a result of friction during processing, micro-domains of

relatively high temperature regions were formed during processing. Temperature increases caused by friction were high enough to cause the formation of AIBN radicals, which initiate the grafting process; however, these

temperature increases are not high enough to result in PP melting.

[77] Zweifel H. Stabilization of polymeric materials. 1st ed. Berlin, New York:

Springer; 1998. p. 219.

[78] Guan Z, Combes JR, Menceloglu YZ, DeSimone JM. Macromolecules 1993;26:

2663e9.

[79] Bird BR, Curtiss CF, Armstrong RC, Hassager O. Dynamics of polymeric liquids. 2nd ed. New York: Wiley; 1987. p. 150.

[80] Cross MM. J Colloid Sci 1965;20:417e37.

[81] Graessley WW, Struglinski MJ. Macromolecules 1986;19:1754e60.

[82] Ferry JD. Viscoelastic properties of polymers. New York: Wiley; 1980. p. 641.

[83] Dealy JM, Wissbrun KF. Melt rheology and its role in plastics processing. New

York: Van Nostrand Reinhold; 1990. p. 665.

[84] Smith B. Infrared spectral interpretation: a systematic approach. 1st ed. Boca

Raton: CRC Press; 1998. p. 288.

[85] Russell KE, Kelusky EC. J Polym Sci Part A Polym Chem 1988;26:2273e80.

[86] Sclavons M, Laurent M, Devaux J, Carlier V. Polymer 2005;46:8062e7.

[87] De Roover B, Devaux J, Legras R. J Polym Sci Part A Polym Chem 1996;34:

1195e202.

[88] Molecular weight averages were evaluated by high-temperature GPC (at

145 C with trichlorobenzene as eluent and triple-detection) at the Polymer

Characterization Lab at the University of Tennessee, Knoxville, TN 37996.

[89] Using trichlorobenzene as solvent, GPC samples were run at 145 C and

analyzed with light scattering, triple detection, and universal calibration. We

used the triple detection data in the analysis described in section 4.3. Similar

results are obtained when Mn and Mw are averaged across the three detection methods. Using averaged Mn and Mw values for neat PP pellets

(Mn ¼ 136,000 g/mol and Mw ¼ 519,000 g/mol) and PP-g-MA/3

(Mn ¼ 126,000 g/mol and Mw ¼ 358,000 g/mol), the percent reduction in

Mn and Mw are determined as 7% and 31%, respectively, very close to the

reductions reported in Section 4.3.

[90] The stoichiometric analysis used here is based on the worst possible scenario, i.e., two PP macroradicals being formed from each chain scission. In

the case where the chain scission occurs as a result of b-scission, only one PP

macroradical will be formed. This will produce fewer PP radicals and, in turn,

require that more MA moieties (i.e., w50 MA units if all scission events occur

solely as a result of b-scission) be attached to each PP chain. This outcome is

much more unlikely than the outcome discussed in section 4.3 and provides

even greater evidence in favor of MA units attached along the PP chain (and

not just at chain ends).

[91] As seen in Fig. 5, none of the samples shows any indication of strain hardening (i.e., increasing viscosity at low frequencies), a well documented

feature associated with long-chain branched polyolefins. (See Auhl, D. et al.;

Macromolecules, 2004, 37, 9465e9472) Based on this observation, we

conclude that under the conditions of SSSP utilized for this study, there is no

significant formation of chain branches during PP-g-MA synthesis.

[92] Based on data presented in Fig. 19 of Ref. [67], interpolations were made to

determine Mw using ho data from oscillatory shear rheology (our samples

were tested at 180 C). The data set cat. A in ref. 67 (representing samples

prepared with the catalyst most commonly employed for PP synthesis in

industry) was used.

[93] Kane MA, Pandey S, Baker GA, Perez SA, Bukowski EJ, Hoth DC, et al. Macromolecules 2001;34:6831e8.

[94] Kim SD, Torkelson JM. Macromolecules 2002;35:5943e52.

[95] Kim S, Roth CB, Torkelson JM. J Polym Sci Part B Polym Phys 2008;46:

2754e64.

[96] Duhamel J. Chen P, editor. Molecular interfacial phenomena of polymers and

biopolymers. Cambridge, England: Woodhead Publishing; 2005. p. 690.

[97] Bu H-S, Cheng SZD, Wunderlich B. Makromol Chem Rapid Commun 1988;9:

75e7.

[98] Heinen W, Rosenmoller CH, Wenzel CB, De Groot HJM, Lugtenburg J, Van

Duin M. Macromolecules 1996;29:1151e7.

[99] Duvall J, Sellitti C, Myers C, Hiltner A, Baer E. J Appl Polym Sci 1994;52:

207e16.

[100] Duvall J, Sellitti C, Myers C, Hiltner A, Baer E. J Appl Polym Sci 1994;52:195e206.

[101] Duvall J, Sellitti C, Topolkaraev V, Hiltner A, Baer E, Myers C. Polymer

1994;35:3948e57.

[102] Dang V, Fezza R, Shu C, Phan T, Song C. J Appl Polym Sci 2007;104:3018e28.

[103] Diop JM, Torkelson JM. Maleic anhydride functionalization of polypropylene

via solid-state shear pulverization, US Provisional Patent filed on Sept. 21

2012.