Balsaflex catalogue - Gurit

advertisement

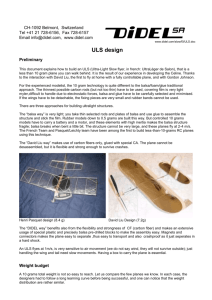

DELIVERING THE FUTURE OF COMPOSITE SOLUTIONS GURIT® BALSAFLEX™ gurit.balsa@gurit.com www.gurit.com Gurit® Balsaflex™ is a classic balsa wood core material with the best balance between weight and resistance for sandwich construction. Its main features are: ¬ High quality composite core material made from end-grain balsa wood ¬ Exceptional shear and compressive strength ¬ From an ecological and renewable resource ¬ Suitable for wind energy, marine, transportation, industrial and other applications ¬ The composite can be produced using hand layup, pultrusion, infusion, pressed moulding, etc Balsa wood is the most ecological core material available on the market. Balsa trees are grown on plantations, in five year cycles. Balsa is a self-generating species in Ecuador, which means that it renews itself quickly without any risk of depletion. Our production centre is located in a balsa wood producing area of Ecuador. From there, we export directly all over the world. Our headquarters are located in Spain. We are considered number one in quality worldwide. This has been achieved due to our rigorous manufacturing process control and quality filters. We started manufacturing Gurit® Balsaflex™ panels in 2002, under the company name ‘Balseurop’. In March 2011 we became part of Gurit Holding, and subsequently changed our company name to ‘Gurit Balsa’. STATE OF THE ART FACILITIES After being cut, the balsa wood is kiln dried. This process ensures dimensional stability of the wood and avoids any phytosanitary risk, guaranteeing the absence of non-desirable living organisms. Strict moisture controls throughout our manufacturing process and the possibility of re-drying wood during our process, allows us to ensure the required moisture content in our final products. We have two warehouses with atmospheric-controlled environments that keep balsa glued blocks in perfect conditions (independently of weather conditions) and ensure the ideal degree of moisture. Gurit Balsa holds a large stock of glued blocks ready to be converted into panels; our current storage capacity is up to 140 containers. This, in addition to two complete production lines used in our manufacturing process, allows us to meet our commitments punctually throughout the whole year. Our production facilities in Ecuador 1 COMPANY CONCEPTS ¬ Complete commitment to our agreements ¬ Customer-oriented company ¬ Traceability of the product through sourcing and manufacturing process ¬ Quality systems ISO 9001 and ISO 14001 certified ¬ Lloyd’s Register approved ¬ Germanischer Lloyd approved ¬ Technical datasheet properties have been tested by a certified laboratory COMPANY VALUES ¬ Respect for the existing traditional balsa wood agriculture and industry in Ecuador ¬ We do not intend to substitute the existing activities in Ecuador. We are contributing with new technology and expertise to the development and improvement of processes, thus allowing the improvement of working and living conditions of all involved in the balsa business ¬ Gurit® Balsaflex™ products and activities respect the environment, working according to the directives and current legal requirements of every country that we work in ¬ Our production centres were created and are currently working under a code of ethics of respect to human rights, protection of the environment and an active participation in cooperation with all people. We assign 1% of our profits to this cause. 2 END GRAIN BALSA PANELS ¬ Flexible panels ¬ Coating ¬ Rigid panels ¬ Perforations ¬ 4’ x 4’ flexible panels ¬ Microgrooves PRODUCT RANGE THICKNESS PRODUCT OPTIONS Inches mm Flexible Rigid Perforations Microgrooves Coating 1/4” 6.4 3/8” 9.5 1/2” 12.7 5/8” 15.9 3/4” 19.1 1” 25.4 1 1/8” 28.6 1 1/4” 31.8 1 3/8” 34.9 1 1/2” 38.1 1 5/8” 41.3 1 3/4” 44.5 2” 50.8 2 1/2” 63.5 3” 76.2 ü ü ü ü ü ü ü ü ü ü ü ü ü û û ü ü ü ü ü ü ü ü ü ü ü ü ü ü ü ü ü ü ü ü ü ü ü ü ü ü ü ü û û ü ü ü ü ü ü ü ü ü ü ü ü ü ü ü ü ü ü ü ü ü ü ü ü ü ü ü ü ü ü All thicknesses available in metric system from 6mm to 55mm for flexible panels and from 6mm to 75mm for rigid panels. 3 SPECIAL FINISHING FOR INFUSION WITH POLYESTER RESIN COATING LENGTHWAYS GROOVES 4 4 - 6.5mm 2" (50.8mm) 1"(25.4mm) 3mm 1” (25.4mm) Ø1/8” (Ø3mm) Ø1/8"(Ø3mm) PERFORATIONS 1"(25,4mm) 3/4” (19mm) Ø1/8” (Ø3mm) 3/4” (19mm) Ø1/8"(ø3mm) 1mm 2.5mm 2” (50.8mm) PERFORATIONS AND MICROGROOVES 3/4"(19mm) 3/4” (19mm) 3/4” (19mm) 2.5mm 1mm MICROGROOVES 3/4"(19mm) 5 DENSITY RANGE ¬ Gurit® Balsaflex™ 110 – When lightness of the resultant composite is the key factor ¬ Gurit® Balsaflex™ 150 – The most demanded density range ¬ Gurit® Balsaflex™ 220 – Highly resistant core, ideal for areas with high strength requirements TECHNICAL DATA PRINCIPAL TECHNICAL DATA UNIT Gurit® Balsaflex™ 110 Gurit® Balsaflex™ 150 Gurit® Balsaflex™ 220 NOMINAL DENSITY Kg/m3 110 155 220 TYPICAL DENSITY RANGE Kg/m3 100-125 135-176 200-242 MPa 10,1 14,1 17,5 COMPRESSION STRENGTH ASTM C-365 COMPRESSION MODULUS ASTM C-365 MPa 3228 4376 5199 SHEAR STRENGTH ASTM C-273 MPa 2,0 3,1 4,3 189 206 SHEAR MODULUS ASTM C-273 MPa 146 Values of this technical data sheet are average values according to the testing standard used. Tests have been carried out by a certified laboratory. It has to be taken into consideration that balsa wood is a natural product influenced by many environmental factors, therefore values indicated herein do not express or imply warranty. FLEXIBLE & RIGID FILLET STRIPS DIMENSION UNIT THICKNESS A DIMENSIONS inches 3/8 1/2 5/8 3/4 1 1 1/4 1 1/2 mm 9.5 12.7 15.9 19.1 25.4 31.8 38.1 inches 1.22 1.42 1.50 1.61 1.77 1.77 1.77 mm 31.0 36.1 38.1 40.9 45.0 45.0 45.0 B inches 0.61 0.59 0.45 0.35 0.16 0.16 0.16 mm 15.5 15.0 11.4 8.9 4.1 4.1 4.1 α (o) 29 29 29 29 31 37 42 B Thickness Length of strip: 2’ (610mm) α A 6 1mm PACKAGING CARDBOARD BOXES Cardboard boxes with sealed plastic bags inside. Recommended for distribution and small consumers. SHRINK-WRAPPED PALLETS: INCREASE PRODUCTIVITY & SAVINGS ¬ Fast access to the panels ¬ Minimal packaging waste ¬ Minimal unpacking handling cost ¬ Maximize container capacity Top carton protection Corner protectors Label Balsa wood panels Plastic wrapping (2 layers) Bottom carton protection Pallet 7 PANEL FORMATS Rigid, flexible or semi-flexible: 1220mm 2” (50.8mm) 610mm 1” (25.4mm) LENGTHWAYS AND WIDTHWAYS SLITS Rigid panel Flexible panel 1” (25.4mm) 1” (25.4mm) 8 LENGTHWAYS SLITS WIDTHWAYS SLITS Semi-flexible panel Semi-flexible panel PANEL FORMATS Special finishings for infusion: Coating, microgrooves, grooves and perforations. All of them can be combined to fit customers’ needs. 2” (50.8mm) 1” (25.4mm) 1” (25.4mm) 1” (25.4mm) 1” (25.4mm) 1” (25.4mm) 1/8” PERFORATIONS EVERY 2” Ø1/8” Total perforations = 288 (Ø3mm) 1/8” PERFORATIONS EVERY 1” Total perforations = 1081 Ø1/8” (Ø3mm) (also every 30mm) 3/4” (19mm) 3/4” (19mm) (also every 30mm) LENGTHWAYS MICROGROOVES WIDTHWAYS MICROGROOVES In one or both sides In one or both sides LENGTHWAYS & WIDTHWAYS MICROGROOVES 2” (50.8mm) 1” (25.4mm) (also every 30mm) 3/4” (19mm) 3/4” (19mm) (also every 30mm) LENGTHWAYS GROOVES In one or both sides 9 C E RT I F I C AT I O N TECHNOLOGICAL CENTER T +34 972 574 514 F +34 972 582 866 gurit.balsa@gurit.com Balsaflex Bro-2-0315 www.gurit.com