SMALL ENGINE DISASSEMBLY

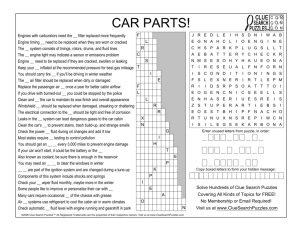

advertisement

SMALL ENGINE DISASSEMBLY Introduction This program will summarize the procedures used to properly disassemble small gas engines. It will explain and demonstrate the most frequently used teardown methods for several types of engine designs. You will discover that there may be more than one way to efficiently remove a component or fastener from these engines. You will learn how organizing engine parts and their fasteners can improve the quality of your work. This video will also stress the importance of following safety rules when working around these engines. The learning material provided in this tape will enable you to acquire a better understanding of small engine operation and repair. The contents of this program should help you become a better small engine technician. Student Objectives After viewing this video, you will be able to: • • • • • • • • • • Inspect a small gas engine for performance problems and damage. Understand the safety rules to follow when working around small gas engines. Properly use a "compression tester" on a small engine. Remove an engine from a lawnmower Properly remove a carburetor and its linkages from a small engine. List some of the procedures used to remove a flywheel from a small engine. Describe how to remove a magneto and other ignition system components from a small gas engine. Remove a cutting blade or drive pulley from a small engine's crankshaft Properly disassemble the valve train assemblies in a valve-in- block engine design and an overhead valve engine design. Remove the internal parts of a small gas engine. To The Instructor This video is designed to be a valuable supplement to your curriculum. Since young people are extremely acclimated to television, it is a natural way to help present important aspects of your subject matter. This video is designed to give a detailed, yet broad coverage of the topic. Most educators agree that it is best to use as many instructional methods as possible. Utilize quality textbooks,' workbooks, videos, lectures, demonstrations, overheads, and other methods to present the technical information. This will hold interest and help pupils understand the large amount of information required to succeed in today's complex world. This video is organized into major sections or topics. Each section covers one major segment of the subject. Graphic breaks are given between each section so that you can stop the video for class discussion, to answer critical questions, to ask questions or perform in-class demonstrations with actual components or parts. This program's format is arranged to be extremely flexible. View it as a full length program, a supplement for lectures, or demonstrations for self-paced individualized instruction. This video allows you to watch only a portion of the program each day or the complete video, depending on your curriculum requirements. The program is designed to simplify the complex. Concise wording and carefully selected graphics are used to provide maximum learning in minimum time. Close-up shots of components and service procedures are used to make every second of viewing instructional, as if each student was standing right behind you, watching over your shoulder while you were working or giving a demonstration. Our technical visual images are designed to match the audio so that every scene has maximum educational value. Computer animation is used to explain difficult to comprehend principles or techniques. Students seem to enjoy the cartoon type images that show how parts work, how they fit together, or how they vary in design. Quiz Answer Key 1. b 2. d 3. b 4. a 5. c 6. c 7. a 8. c 9. d 10. d 11. a 12. b 13. b 14. d 15. b Use your own judgement to evaluate the definitions, definition type questions, and discussion topics. Technical Terms Write definitions for the following terms. Use a textbook or review the video if needed. oil sump, electronic stethoscope, engine piston, connecting rod assembly, spark plug, compression tester, piston rings, engine valves, cylinder head, head gasket, fuel tank supply valve, fuel tank, fuel lines, ratchet, six-point socket, air cleaner, carburetor, carburetor throttle shaft, engine governor, engine muffler, chisel, flywheel, flywheel cover, magneto, magneto primary wire, one- way clutch, engine crankshaft, pry bar, wheel puller, contact points, condenser, electronic ignition, rust penetrant, valve-in- block engine, valve cover, valve spring, valve keeper, valve spring compressor, overhead valve engine, engine cylinder wall, ring ridge, ridge reamer tool, engine block, camshaft, lifters, crankcase, oil slinger, TDC Video Discussion Topics Here are a few topics that might be used for a class discussion. 1. What type of problems should you look for before disassembling a small engine? 2. Name the safety rules that should be followed when working around small gas engines. 3. What parts should be removed first when disassembling a small gas engine? 4. Why is it important to note the location of any linkages or springs when removing a carburetor from a small engine? 5. Name some of the methods used to remove a flywheel from a smail engine. 6. Why should all parts and fasteners be organized during a small engine teardown? 7. Describe how to properly remove a pulley from a small engine's crankshaft? 8. Describe how to remove a "ring ridge" from a small engine's cylinder wall. Video Quiz Print the appropriate letter in the blank to indicate the most correct answer after reading the statement: 1. When inspecting a small gas engine for problems, you should use a __________ or __________ stethoscope to listen for internal mechanical noises. a. conventional, electrical b. conventional, electronic c. conventional, magnetic d. none of the above 2. If a small engine knocks when cold, a loose ________ may be the source of trouble. a. ring b. head c. seal d. piston 3. If a small engine's spark plug is oil fouled, bad _________ or _________ are probably the cause of the cause of the problem a. lifters, valves b. rings, seals c. valves, springs d. all of the above 4. Some small gas engines are equipped with a compression release mechanism that lowers __________ pressure for easy starting. a. compressIon b. oil c. crankcase d. manifold 5. If a small engine's spark plug is physically damaged, a(n) ____________ malfunction is generally the problem. a. electronic b. electrical c. mechanical d. magneto 6. A low compression reading from a small gas engine would normally indicate a(n) __________ leak in the combustion chamber . a. exhaust b. fuel c. pressure d. manifold 7. An extremely dirty air filter element usually indicates improper maintenance that has probably caused major damage to the engine's ___________ components. a. internal b. ignition c. external d. exhaust 8. To remove a small engine's ___________, it is sometimes necessary to straighten locking washers on the mounting bolts. a. flywheel b. magneto c. muffler d. camshaft 9. The magneto __________ wire must be unplugged or disconnected before a small gas engine's magneto can be removed. a. starter b. armature c. stator d. primary 10. Before removing the __________ from a small engine, you must first remove the screen shield mounted over it. a. breather b. starter c. governor d. flywheel 11. Many older small engines still have ______________ and a _____________ under a small aluminium cover below the flywheel. a. points, condenser b. points, magneto c. resistors, magneto d. capacitors, magneto 12. When removing the valves from a valve-in-block engine, a spring compressor should be used to compress each valve spring so that you can remove the valve ____________. a. guides b. keepers c. seals d. seats 13. To remove the valves from an overhead valve engine, use a soft faced mallet to rap the ___________ to help free the ___________. a. guides, seats b. retainers, keepers c. seats, seals d. keepers, retainers 14. When all the crankcase cover bolts have been removed, tap on the cover with a mallet to free the _______ so you can lift the cover off the block. a. lifters b. camshaft c. rod d. gasket 15. A long chisel should be used to bend the ___________ bolt lock washers out of the way. a. camshaft b. rod c. crankshaft d. all of the above Short Answer Briefly answer the following questions in your own words: 1. What type of damage can result if a small engine is operated with little or no oil in its crankcase? 2. Explain how to use a compression tester on a small gas engine. 3. Describe how to remove a fuel tank and fuel lines from a typical small engine. 4. What procedures are normally used to remove an engine from a lawnmower? 5. Why should you use caution when removing a small engine's carburetor springs and linkages? 6. Describe how to remove a one-way clutch from a small engine's crankshaft snout. 7. How do the valve trains in a valve-in-block engine and an overhead valve engine differ? 8. What are normally the easiest parts to remove in a four-stroke cycle small engine crankcase? 9. What tools are usually required when removing the connecting rod from a small engine's crankshaft? 10. Describe how to remove the cylinder head from an over-head valve small gas engine.