Experimental investigation into the behavior and influence of water

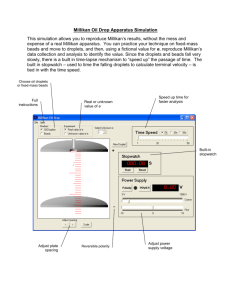

advertisement