particulate flows

advertisement

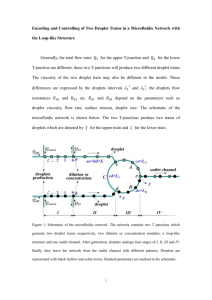

Analysis of droplet breakup at liquid blast furnace injections C. Jordan, C. Maier, Z. Hersfalvi, B. Kiss, J. Nagy, M. Harasek Vienna University of Technology, Institute of Chemical Engineering, Getreidemarkt 9/166, A-1060 Vienna; tel.: +43-1-58801-15924, fax.: +43-1-58801-15999, e-mail: christian.jordan@tuwien.ac.at The injection of liquid hydrocarbons like heavy fuel oil and crude tar from coke production is a common way to reduce the coke consumption in an iron blast furnace. This is practiced e. g. at Blast Furnace A of voestalpine Stahl GmbH (Linz, Austria). In this work, a more in depth-study of the droplet breakup within the raceway is carried out. Especially the effects of changes in surface tension and viscosity of the fluid were evaluated using a lab scale cold model of the raceway section of the blast furnace. Applying high speed imaging and image processing the droplet size at varying operating conditions have been studied. The results have been used to set up a correlation for the prediction of the resulting droplet sizes within the industrial plant. Furthermore the capabilities of computational fluid dynamics to model this type of flow have been tested: The open source CFD package OpenFOAM has been used to simulate the jet breakup in the shear flow. Time resolved numerical processing has been done at VSC2 (Vienna Scientific Cluster 2). Acceptable agreement of the liquid phase distribution with the experimental results has been found. Finally the droplet breakup mechanisms have been analysed: literature covers many cases of single droplet breakup taking place in homogeneous outer shear flow – however, at the injection lance tip there is a large velocity gradient introducing additional asymmetric shear on the fluid surface, which makes shear induced entrainment as major breakup effect. The resulting dimensionless model can be used to determine the droplet sizes of injected liquids and thus the evaporation and combustion characteristics within the blast furnace raceway. This way optimum operating conditions can be set when changing the injected fluids. We want to thank our partners in the FFG/K1Met framework for their support: C. Feilmayr and C. Thaler (voestalpine Stahl GmbH, Linz, Austria), S. Puttinger and S. Pirker (CD-Labor for Particulate Flows, JKU Linz, Austria)