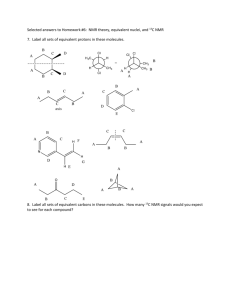

Isobutylene Dimerization Repackaged as a Problem

advertisement

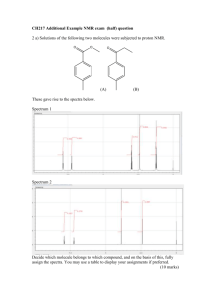

Isobutylene Dimerization Repackaged as a Problem‐Based Exercise Mariah Schuster, Karl P. Peterson, and Stacey A. Stoffregen Department of Chemistry University of Wisconsin ‐ River Falls, River Falls, WI, 54022 INTRODUCTION The dimerization of isobutylene produced by the dehydration of tert‐butyl alcohol was extensively studied in the 1930’s.1a‐c This dimerization reaction has been commonly used as an example of alkene dimerization in organic chemistry textbooks and has been the basis of a preparative laboratory exercise that allows students to verify the expected results.2‐4 One limitation of this experiment as a preparative exercise is that two isomeric octenes are produced and analyzed as a mixture. Additionally, the reaction produces the less substituted octene isomer as the major component of the product mixture. We have repackaged this experiment as a problem‐based, culminating experience in our organic chemistry laboratory. Students are given a procedure for conducting the reaction and isolating the product, for which the composition and structures are not provided. Students then use a combination of GC‐MS, IR, 1H NMR, 13C NMR, and molecular modeling to determine that the product contains a mixture of two isomeric octenes and to solve the structures of the two compounds. Additionally, students are asked to propose a reasonable stepwise mechanism for the transformation and to explain the unusual product distribution using the results from computations. The exercise gives students the opportunity to apply a range of instrumental techniques to a chemical reaction for which the product structures are not known to them. E. 1H NMR Spectroscopy: The 1H NMR spectrum was taken on a Bruker DPX‐200 at 200 MHz using CDCl3 containing 0.03% TMS (Figure 5). All of the signals for both products are completely resolved. The signals present as clean singlets or as singlets with very small, indiscernible coupling. The major product shows a t‐butyl signal at 0.92 ppm, an allylic methyl signal at 1.77 ppm, an allylic methylene signal at 1.93 ppm, and two vinylic signals at 4.62 and 4.82 ppm. The minor product show a t‐butyl signal at 1.08 ppm, two allylic methyl signals at 1.66 and 1.71 ppm, and a vinylic signal at 5.16 ppm. D G H B A E F major C I minor THE EXERCISE A. Procedure: A 15.0 mL sample of 2‐methyl‐2‐propanol was slowly added to 32 mL of 9 M sulfuric acid in a 100 mL round‐bottomed flask. The reaction mixture was heated to a gentle reflux for 30 minutes. The heat was removed from the reaction flask and the reaction mixture was allowed to cool to room temperature. The two‐phase reaction mixture was transferred to a separatory funnel. The lower acid layer was removed and the organic layer was washed with water (2 x 10 mL) and 5% sodium bicarbonate solution (1 x 10 mL). The organic layer was dried over sodium sulfate and purified by simple distillation. The fraction that distilled from 98‐106 oC was isolated and analyzed. B. Gas Chromatography‐Mass Spectrometry: The sample was injected in a Varian Saturn 2000R GCMS using a 30 meter Varian CP‐Sil 8 CB lowbleed column and a constant temperature of 50 °C. The chromatogram clearly indicates the presence of two compounds in a ratio of ~3.5 to 1 (Figure 1). I 1H B A 9H 9H E F 3H 2H D C 3H 3H H G 1H 1H Figure 5: 1H NMR spectrum of the product mixture. F. 13C NMR Spectroscopy: The 13C NMR spectrum was taken on a Bruker DPX‐200 at 50 MHz using CDCl3 containing 0.03% TMS (Figure 6). All of the signals for both products are completely resolved. There are eight aliphatic signals at 18.78, 25.25, 17.98, 30.06, 31.16, 31.34, 32.07 and 51.68 ppm. There are also four vinylic signals at 113.70, 130.20, 135.04 and 144.06 ppm. Figure 1: Chromatogram from GCMS analysis. C. Mass Spectrometry: The mass spectrum of the major product gave a molecular ion of 112 amu and a major fragment of mass 57 amu from allylic cleavage of the C3‐C4 bond (Figure 1). The mass spectrum of the minor product gave a molecular ion of 112 amu and major fragments at 97 from the allylic fragmentation of the C4‐C5 bond, and 57 and 55 amu from the vinylic fragmentation of the C3‐C4 bond (Figure 3). Figure 6: 13C NMR spectrum of the product mixture. G.Computations: The relative energies of the product molecules were calculated using Gaussian. Optimizations were performed at the B3LYP/6‐31G(d) level. Minima were confirmed with vibrational frequency analysis. The trisubstituted, minor product energy was estimated to be 2.3kcal/mol lower in energy than the disubstituted major product. The structure of the common cationic intermediate leading to the formation of the two products was also optimized at B3LYP/6‐31G(d). The optimized structure, shown in Figure 7a, is oriented for visualization down the methyl‐Carbocationic C bond (i.e. C13‐ C12). Figure 7b, is oriented for visualization down the methylene‐Carbocationic C bond (i.e. C11‐C12).The Lowest Unoccupied Molecular Orbital (LUMO) is shown on the right. Figure 7a Figure 2: Mass spectrum of the major product. orbital on C12 The structure of the optimized carbocation intermediate indicates that H14 on methyl C13 is coplanar with the empty p orbital of cationic C12, while H21 and H22 on methylene C11 lie at approximately a 22° angle from the C11‐C12‐C13‐C17 plane. A 360° coordinate scan of the C22‐C11‐C12‐C17 dihedral angle indicates a 4.4kcal/mol barrier to rotation of H22 into a coplanar position relative to the empty C12 orbital. DISCUSSION Students are generally able to interpret much of the data with minimal supplemental instruction. • Gas chromatography: Students determine that the reaction generates two products in a ratio of ~3.5:1. • Mass spectrometry: Students determine that the two products are isomers with a molecular weight of 112 amu. Most students generate a formula of C8H16 (one unsaturation), although some students will also consider C7H12O briefly. Students are not experienced enough with mass spectral data interpretation to use the fragmentation data to solve for the structures, but they are able to identify reasonable fragmentation events once the product structures are known. • Infrared spectroscopy: Students identify that the spectrum clearly indicates the presence of a C=C, although many student do not initially account for the geminal disubstitution signal at 892 cm‐1. The trisubstitution signal at ~825 cm‐1 is nearly always overlooked by students until the structure of the minor product is solved. • 1H NMR spectroscopy: Students are initially presented with the challenge of determining which signals are for each of the two compounds. A confounding factor is that the ratio of the products is often ~3.5:1, which causes a 1H signal in the minor product to integrate nicely with a 1H signal in the major product. The overall integration becomes nonsensical at that point, which encourages students to reevaluate their integration work. Students are told that all of the signals should be considered as singlets, despite the fact that very minute coupling can be observed. Students are not experienced with geminal or allylic coupling and are not expected to interpret the coupling data to solve the structures. Additionally, students are not expected to uniquely identify the vinylic protons in the major product (Figure 5: G and H) or the allylic methyls in the minor product (Figure 5: C and D). • 13C NMR spectroscopy: Students confirm the presence of four vinylic carbons and eight types of aliphatic carbons. Students are not expected to further assign the signals. • Molecular modeling: Students are able to confirm that the trisubstituted alkene is lower in energy than the geminally disubstituted alkene. This leaves them to reconcile why the more stable product is not the major product as would be expected for this type of reaction. Students are asked to propose a reasonable stepwise mechanism for the reaction and to comment on the unusual product distribution. Writing the mechanism proves to be somewhat challenging, although most students eventually associate the nucleophilic character of alkenes with the electrophilic character of carbocations, both of which the have studied extensively. Student are generally able to correctly apply statistical arguments for rationalizing the kinetic preference for the less substituted alkene product. Additionally upon examination of the LUMO of the optimized carbocation, students recognize the steric constraints of the tert‐butyl group, preventing methylene Hs from readily adopting the required coplanar orientation relative to the empty p orbital for alkene formation. The coordinate scan supports the kinetic rational for the observed product distribution. CONCLUSIONS The preparation of isobutylene dimers has been successfully repackage as a problem‐ based experiment for the organic laboratory. Students have found studying this alkene dimerization reaction to be rewarding and intellectually challenging. They are able to apply many of the laboratory skills that they have learned throughout the organic chemistry laboratory course. The desired outcomes of the exercise include: • reinforcement of basic laboratory techniques • introduction to the analysis of mixed samples • reinforcement of GC, MS, IR, 1H NMR, 13C NMR and molecular modeling data acquisition and analysis • application of data analysis and critical thinking skills REFERENCES Figure 3: Mass spectrum of the minor product. D. Infrared Spectroscopy: The infrared spectrum of the product mixture provided strong indications of alkene functionality. There is a vinyl C‐H stretch at 3076 cm‐1, aliphatic C‐H stretches from 2867‐2955 cm‐1, and a C=C stretch at 1641 cm‐1. There is a prominent geminal disubstitution signal at 892 cm‐1 from the major product and a small trisubstitution signal at ~825 cm‐1 from the minor product, 13 14 C H C C Figure 7b ACKNOWLEDGEMENTS orbital on C12 C H Funding for this project was provided by the University of Wisconsin – River Falls Chemistry Department, College of Arts and Sciences and Provost’s Office, and by the National Science Foundation CCLI program (Grant DUE‐ 0736504). C CH2 11 Figure 4: Infrared spectrum of the product mixture. 1. a. Whitmore, F. C.; Wrenn, S. N. J. Am. Chem. Soc. 1931, 53, 3136. b. Tongberg, C. O., Pickens, J. D.; Fenske, M. R.; Whitmore, F. C. J. Am. Chem. Soc. 1932, 3706. c. Whitmore, F. C. ; Church, J. M. J. Am. Chem. Soc. 1932, 54, 3710. 2. Allen, M.; Joyner, C.; Kubler, P. G.; Wilcox, P. J. Chem. Educ. 1976, 53(3), 175. 3. Tremelling, M. J.; Hammond, C. N. J. Chem. Educ. 1982, 59(8), 697. 4. Mohrig, J. R.; Hammond, C. N.; Morrill, T. C.; Neckers, D. C. Experimental Organic Chemistry. A Balanced Approach: Macroscale and Microscale, p78‐84. W.H. Freeman and Company, New York ,1999. Computations were performed on the Midwest Undergraduate Computational Chemistry Consortium computer cluster at Hope College.