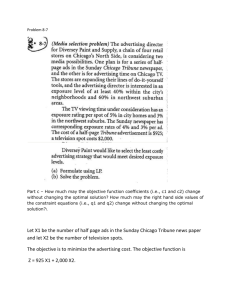

Linear Programming Introduction & Giapetto's Example

advertisement