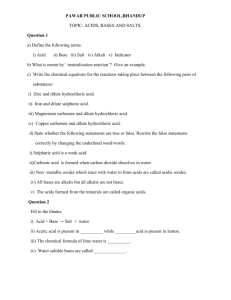

standard methods for the analysis of oils, fats and

advertisement