Powered Aircraft Flight Controls: Evolution & Technology

advertisement

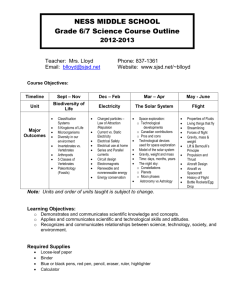

Evolution of Powered Aircraft Flight Controls Tom Greetham Evolution of Powered Flight Controls February 10, 2012 1 Agenda 1. Introduction 2. Flight Control Basics 3. Un-powered Flight Controls 4. Powered Flight Controls 5. Stability Augmentation 6. Aircraft Control System Examples 7. Fly By Wire 8. Power By Wire 9. Aircraft Business Trends 10. Related SAE Publications Evolution of Powered Flight Controls February 10, 2012 2 Who Is This Guy? Tom Greetham • Ohio State University, B.S.M.E. 1981 & M.S.M.E 1982 • Moog Inc., Aircraft Group Engineering Manager, Military Actuation • Flight Control Actuation Experience – B-2 Flight Control Actuation System (Simulation, System Verification Testing) – LCA (Light Combat Aircraft) – Indian Airforce – V-22 Tilt Rotor Aircraft – Bombardier Challenger 300 Mid-size Business Jet Evolution of Powered Flight Controls February 10, 2012 3 Moog Inc. • Moog Is a Worldwide Manufacture of Motion Control Components and Systems for Industrial, Medical and Aerospace Applications • Moog’s Aircraft Group Is the Company’s Largest Business Segment and Is a Leading Manufacture of Aircraft Control Components and Systems, Mostly for Flight Control Applications Evolution of Powered Flight Controls February 10, 2012 4 What Are Aircraft Flight Controls? • Flight Controls (on Fixed Wing Aircraft) Are the Control Surfaces and the Systems that Move Them to Control the Aircraft Attitude – – – Pitch (a.k.a. Longitudinal) Roll (a.k.a. Lateral) Yaw (a.k.a. Directional) yaw axis elevator aileron pitch axis flap rudder pedals control column rudder elevator flap aileron roll axis Evolution of Powered Flight Controls February 10, 2012 5 What Are Powered Flight Controls? • Powered Flight Controls Have Actuators that Provide Significant Force Augmentation to the Pilot to Move the Control Surfaces • Increasingly Necessary for Larger Aircraft and/or those Flying at Higher Airspeeds Evolution of Powered Flight Controls February 10, 2012 6 Flight Control Technology Chronology Entered Service Technology Un-Powered Military 1910s Commercial 1920s Powered Boost 1940s 1940s 3000 psi Hydraulics 1940s 1950s Auto Pilots 1950s 1950s Fully Powered, with Reversion 1950s 1960s (Boeing 727) Fully Powered, without Reversion 1950s (B-47) 1970 (Boeing 747) Fly-By-Wire 1970s (F-16) 1980s (A-320) Digital Fly-by-Wire 1970s 1980s (A-320) 5000 psi Hydraulics 1990s (V-22) ~2005 (A-380) Power-By-Wire ~2006 (F-35) ~2005 (A-380) Evolution of Powered Flight Controls February 10, 2012 7 Flight Control Design Drivers • Safety, Safety, SAFETY – – – Design for <10-9 Critical Failures per Flight Hour (That’s one failure per billion hours) Redundancy Conservative Design Philosophies • Resist Deviating from What Is Known to Work • More Prevalent in Commercial Aviation Than in Military • Reliability – Minimize Complexity to Minimize Maintenance Actions (at Odds With Redundancy Above) • Minimum Weight – Cost-to-Weight Trade-off: • Commercial: ~$1000 per pound per aircraft (updated) • Military: ~$2,000-$10,000 per pound per aircraft (8 Year Old Data) • Cost Evolution of Powered Flight Controls February 10, 2012 8 Un-Powered Flight Controls Pitch Up Command Control Column Manual Trailing Edge Up Result Horizontal Tail Pitch Up Command Elevator Control Column Trailing Edge Up Result Servotabs Elevator Horizontal Tail Evolution of Powered Flight Controls February 10, 2012 9 Servotab Simple Hydromechanical Servoactuator • Power Provided by High Pressure Hydraulic Fluid • Similar to an Automobile Power Steering System Pilot Input Ps R Hydromechanical Servoactuator Control Surface Evolution of Powered Flight Controls February 10, 2012 10 Powered Boost • Hydraulic Servoactuated Surface Control (Servotab Locked) • Force Feedback to Pilot – • Force Proportional to Actuator Load is Applied to Valve Input Link so that Pilot Feels Surface Loads Mechanical Reversion Mode – – – If Hydraulics Fail Actuator Output and Surface Released to Move Freely Pilot Input Moves Unlocked Servotab 'Boost' Servoactuator (Moving-Body with Pressure Feedback and Tab Lock) Elevator Horizontal Tail Evolution of Powered Flight Controls February 10, 2012 11 Servotab Fully Powered Flight Controls With Reversion Mode • Mechanical Reversion Mode – Actuator Reverts to Bypass Mode – Servotab Unlocked to “Fly” the Surface • Pilot “Feel” Provided by Hydromechanical Feel and Trim System 'Irreversible' Servoactuator (Dual-Tandem, Fixed-Body with or without Tab Lock) Feel/Trim Elevator Horizontal Tail Evolution of Powered Flight Controls February 10, 2012 12 Servotab Fully Powered Flight Controls, No Reversion Mode • No Mechanical Reversion Mode – Control Forces Too High For Pilot to Move Surface Sufficiently to Control Flight – Failures Covered by Redundant Actuators or Surfaces and Redundant Hydraulic Systems (More On That Later) • Pilot “Feel” Provided by Hydromechanical Feel and Trim System Xp Control Column Ps R Feel and Trim Xs = Xp Evolution of Powered Flight Controls February 10, 2012 13 Xs Hydromechanical Servoactuator Control Surface Autopilots • Autopilot Actuators “Fly” the Pilot Input Linkage and Control Column Via Commands from an Autopilot Computer • Pilots Can Overpower Runaway (Failed) Autopilot • Autopilot and Feel Systems Provide Pilot Visual and Tactile Feedback, Features Otherwise Lost by Powered Flight Controls Xa Xp Autopilot Control Column 'FBW' Autopilot Servoactuator Ps R Feel and Trim Xs = Xp = Xa Xs Hydromechanical Servoactuator Control Surface Evolution of Powered Flight Controls February 10, 2012 14 Stability and Control Augmentation • Inputs from Sensors and a Fight Control Computer Are Summed With Pilot or Autopilot Inputs to Improve the Aircraft Stability and Handling Qualities • Unlike Autopilot Inputs, Stability and Control Inputs Do Not Move the Pilot’s Control Column PFCS Xp Aircraft Sensors Xd Control Column 'FBW' Series Damper Servoactuator Ps R Feel and Trim Xs = Xp + Xd Evolution of Powered Flight Controls February 10, 2012 15 Xs Hydromechanical Servoactuator Control Surface Boeing 757 Elevator Control System Evolution of Powered Flight Controls February 10, 2012 16 F-111 Pitch and Roll Control System Evolution of Powered Flight Controls February 10, 2012 17 F-15 Pitch-Roll Control Assembly (A.K.A. Hydraulic Television Set) 70 lbs 16” Evolution of Powered Flight Controls February 10, 2012 18 Fly-By-Wire • Mechanical Links Between the Pilot Controls and Surface Actuators Are Replaced by Electronics • This Offers a Significant Weight Savings Over Hydromechanical Systems • Requires Sophisticated Failure Management Techniques • Early Fly-By-Wire Aircraft Used All Analog Electronics Aircraft Sensors Autopilot Airbus & Boeing Xp Boeing only Control Column PFC Loop Closure Circuitry Electrohydraulic Servovalve (EHV) Autopilot Acts Ps R Feel and Trim LVDT Xs Transducers Control Surface Evolution of Powered Flight Controls February 10, 2012 19 Fly-By-Wire Actuators • Actuator Position Control Loop Implemented With Electronics, Rather than Linkages – – • Actuator Motion Determined by an Electronically Controlled Servovalve Actuator Position Feedback Provided Electronically by a LVDT Position Transducer Bypass Valve Allows Surface to Be Controlled Freely by Another Actuator Servovalve In Case of Failure Commands EHV Servovalve Solenoid-Oerated Pilot Valve (SOV) Ps R Bypass Valve LVDT Evolution of Powered Flight Controls February 10, 2012 20 Digital Fly-By-Wire • First Generation Fly-By-Wire Electronics Were Analog – Uncertain Reliability and Failure Modes of Digital Processors • Industry Has Transitioned to Digital Control Electronics – System Complexity Growing Exponentially – Reliability of a Single DSP (Digital Signal Processor) Predicted to Be Better than that of Accumulated Analog Components – Maturing DSP Failure Management – Many of the Typical Early System Changes Are More Easily Made In Software Without Requiring Hardware Changes • However, Software Changes Still Come at a High Price • Commercial Aircraft Use Digital Flight Control Electronics, but Often Use Analog Reversion Modes – Example of Conservative Design Philosophy Evolution of Powered Flight Controls February 10, 2012 21 FBW Primary Surface Actuator Schematic (With Damped Fail-Safe Mode) Active Mode • Actuator motion responds to electrical commands to servovalve (EHSV) Damped Mode • Cylinder chambers connected together through an orifice • Actuator moves with external forces • Damping suppresses flutter • Compensator provides emergency fluid Note: Solenoid Shown Enegized Manual Test Valve Inlet Filter Compensator / Indicator & Relief Valve Damping SOV (single coil) EHSV LVDT Typical Components • Inlet Filter (Screen) • Inlet check valve • Servovalve with LVDT • Mode Select Valve • Damping Solenoid Valve • Piston & Cylinder with LVDT • Compensator with Manual Release • Load Relief Valves • Pressure Transducers (Optional) Mode Select Valve (Active, Damped) AntiCavatition Absolute Pressure Transducers Load Relief Valve LVDT Evolution of Powered Flight Controls February 10, 2012 22 Aileron Balanced Actuator FBW Spoiler Surface Actuator Schematic Active Mode • Actuator motion responds to electrical commands to servovalve (EHSV) Fail-Safe Mode • EHSV biased to drive actuator to retract (surface moves down) • Loss of hydraulic Power Hold-down check valve prevents actuator from extending (surface upfloat) Hold-down check valve allows surface to freely retract (surface down) Typical Components • Inlet Filter (Screen) • Inlet check valve • Servovalve with LVDT • Anti-Extend Valve With Manual Release • Piston & Cylinder with LVDT • Load Relief Valve Evolution of Powered Flight Controls February 10, 2012 23 F-18 E/F Horizontal Tail Dual Tandem Actuator Quad, Direct-Drive, Dual Tandem Shutoff Valve Quad, Rotary-Linear, Dual Tandem Direct-Drive-Valve QUAD LVDT 1 2 3 4 Inlet Check Valve Ps2 Ps1 Inlet Screen Inlet Screen Inlet Check Valve Restrictor/Check Valves for Neutral Lock Fail Safe Mode R2 R1 Return Line Compensator Two-Position Bypass Valve Logic Piston Three-Position Mode Select Valve Anti-Cavitation Valves QUAD LVDT Partially-Balanced, Dual-Tandem Actuator • Dual Hydraulic Supplies Feed Separate but Connected Pistons • Quad Redundant Electrical Channels – Quad Servovalve and Shutoff Valve Coils – Quad Servovalve and Ram Position Transducers (LVDTs) • Direct Drive Servovalve Evolution of Powered Flight Controls February 10, 2012 24 Relaxed Stability Aircraft Trim Force C.G. Center of Lift • C.G. Always Located Forward of Center of Lift for Positive Stability • Modern Fly-By-wire Aircraft Are Designed With Reduced Distance Between the Center of Gravity (C.G.) and Center of Lift – – – – Requires Smaller Surfaces and Forces • Reduced Weight and Cost Requires Lower Trim Loads (Less Drag) Reduces Aerodynamic Airframe Stability (Less Tendency to Fly Straight) Requires More Control Loop Augmentation • Active Damping for Example • Higher Dynamic Response Evolution of Powered Flight Controls February 10, 2012 25 System Pressure • When Hydraulics Were Introduced to Aircraft in the 1930s and 40s They Operated at ~1,500 psi • In the 1950s 3000 psi Became the Standard • Increasing System Pressure Enables Higher Actuator Forces and/or Smaller Sizes – Smaller Actuators Demand Lower Flow Rates – Lower Flow Rates Enable Smaller Tubing and Pumps; Thus Reduced Weight • But Higher Pressures: – Increase Hydraulic Component Fatigue Stresses – Decreased Actuator Dynamic Stiffness, Because Actuators Are Smaller, Increasing Control Surface "Flutter" Vulnerability • Flutter Is an Aeroelastic Phenomenon In Which a Control Surface Becomes Violently Unstable If Not Restrained Adequately Evolution of Powered Flight Controls February 10, 2012 26 Power-By-Wire • Traditionally, Hydraulics Has Been the Technology of Choice for Powered Flight Controls – – – – – High Power Capability High Reliability Compact Components Distribution (Long Hydraulic Lines) Provides Natural Cooling Reliable Fail-Safe Modes • Advances In Electronics and Magnetics Has Made Electric Actuators Become More Attractive – Magnets and Magnetic Materials – Electronics Reliability – Computer Power • Electric Actuation Offers Some Advantages Over Centralized Hydraulics – Fewer Leaks – Can Remove Components Without Breaking Into Hydraulic Lines – Easier To Physically Separate Redundant Electrical Systems than Hydraulic Systems Evolution of Powered Flight Controls February 10, 2012 27 Electrohydrostatic Actuators (EHAs) • Actuator is an Electrically Powered Self Contained Hydraulic System • No External Hydraulic Connections • Actuator Motion Proportional to Motor/Pump Rotation • Adding a Bypass Valve Across the Ram Piston Provides a Reliable FailSafe Mode Velocity Command Motor Controller M Variable Speed Motor Fixed Displacement Pump Evolution of Powered Flight Controls February 10, 2012 28 Tandem Electrohydrostatic Actuator and Power Control Electronics Evolution of Powered Flight Controls February 10, 2012 29 Business Trends • Aircraft Builders Increasingly Are Subcontracting Larger Systems to Other Companies – Shifts Risks and Costs from Airframers to Suppliers • Fun and Headaches, Too – Examples: • • • • B-2 Flight Control Actuation System (Moog) Boeing 777 Flight Control Actuation System (Teijin Seiki) F-35 Flight Control Actuation System (Moog/Parker Hannifin) Boeing 787 Flight Control Actuation System • In Commercial Aviation Pressure to Reduce Costs has Become Brutal • Consolidation of Industry – More Teaming Arrangements On New Aircraft • Cost and Risk Sharing – Acquisitions Evolution of Powered Flight Controls February 10, 2012 30 Related SAE Publications • Books – Raymond, E.T., C.C. Chenoweth, Aircraft Flight Control Actuation System Design • Documents – ARP1281D: General Specification For Power Operated Hydraulic Flight Control Actuators – ARP490F: Electrohydraulic Servovalves – ARP4493A: Direct Drive Servovalves – AS94900 : Aerospace - General Specification for Flight Control Systems Design, Installation and Test of Piloted Military Aircraft – ARP4386C : Terminology and Definitions for Aerospace Fluid Power, Actuation and Control Technologies – ARP5007 : Development Process - Aerospace Fly-By-Wire Actuation System – AIR4253A: Description of Actuation Systems for Aircraft With Fly-By-Wire Flight Control Systems Evolution of Powered Flight Controls February 10, 2012 31