SAND - Honeywell Process Solutions

advertisement

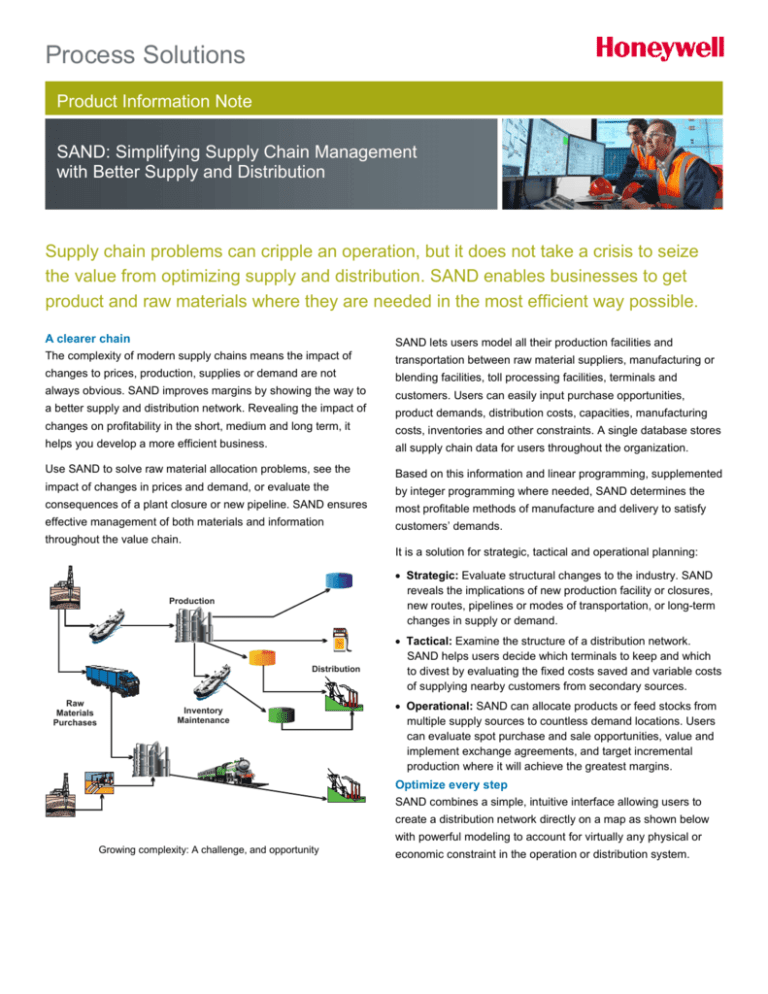

Process Solutions Product Information Note SAND: Simplifying Supply Chain Management with Better Supply and Distribution Supply chain problems can cripple an operation, but it does not take a crisis to seize the value from optimizing supply and distribution. SAND enables businesses to get product and raw materials where they are needed in the most efficient way possible. A clearer chain SAND lets users model all their production facilities and The complexity of modern supply chains means the impact of transportation between raw material suppliers, manufacturing or changes to prices, production, supplies or demand are not blending facilities, toll processing facilities, terminals and always obvious. SAND improves margins by showing the way to customers. Users can easily input purchase opportunities, a better supply and distribution network. Revealing the impact of product demands, distribution costs, capacities, manufacturing changes on profitability in the short, medium and long term, it costs, inventories and other constraints. A single database stores helps you develop a more efficient business. all supply chain data for users throughout the organization. Use SAND to solve raw material allocation problems, see the Based on this information and linear programming, supplemented impact of changes in prices and demand, or evaluate the by integer programming where needed, SAND determines the consequences of a plant closure or new pipeline. SAND ensures most profitable methods of manufacture and delivery to satisfy effective management of both materials and information customers’ demands. throughout the value chain. It is a solution for strategic, tactical and operational planning: • Strategic: Evaluate structural changes to the industry. SAND reveals the implications of new production facility or closures, new routes, pipelines or modes of transportation, or long-term changes in supply or demand. Production Distribution Raw Materials Purchases Inventory Maintenance • Tactical: Examine the structure of a distribution network. SAND helps users decide which terminals to keep and which to divest by evaluating the fixed costs saved and variable costs of supplying nearby customers from secondary sources. • Operational: SAND can allocate products or feed stocks from multiple supply sources to countless demand locations. Users can evaluate spot purchase and sale opportunities, value and implement exchange agreements, and target incremental production where it will achieve the greatest margins. Optimize every step SAND combines a simple, intuitive interface allowing users to create a distribution network directly on a map as shown below with powerful modeling to account for virtually any physical or Growing complexity: A challenge, and opportunity economic constraint in the operation or distribution system. SAND: Simplifying Supply Chain Management with Better Supply and Distribution 2 be assigned to each processing unit, with production limits for each to allow different operations to share the same capacity restrictions. Where product switchover times and costs are significant or products must be sequenced in a certain order, integer programming can be added to the basic LP approach to improve model accuracy. Inventory control Define period-specific minimum and maximum levels for any material at any location; specify opening and closing inventories; and apply minimum and maximum limits on any group of materials or locations. Assigning the proper economic value to inventory and providing meaningful limits allows SAND to reveal the optimal production against inventory changes at locations A simple map interface makes it easy to add locations. Limitless Locations Model any number of locations with standard tables available to throughout the distribution network. Customer demands Where production capacity is limited and allocation of incremental sales must be prioritized, demand volumes can be assign capacity limitations to terminals and assign location- modeled as maximums for SAND to select the appropriate specific or material-specific costs to a variety of activities, such product slate for the most profitable markets. Where demand as shipping, receiving and inventory. volumes are predictable, they can bet represented as fixed Supply Availability & Cost Material costs can be modeled where they are purchased and quantities. Alternatively, a hybrid method can fix contractual transported by the model to the proper locations, or entered opportunities. directly at the blending or processing facility on a delivered cost basis. Use external spot prices, contract purchase costs or Exchange agreements SAND can model complex agreements for the exchange of internal transfer prices. Purchases can also be entered in steps different materials, including multiple delivery and receipt to approximate a supply curve, and integer programming used for locations and different modes of transportation. Exchange volume discounts. balancing mechanisms by individual materials or material groups This ensures targets are within boundary limits, and provides a can be set up to balance exactly, or to within specified work process for creating, validating, approving and activating percentage or absolute tolerances. instructions. It can also integrate with a plant’s planning, Multi-period capabilities Multi-period modeling enables users to optimize inventory levels scheduling, and ERP systems. Transport Model both continuous modes of transport such as pipelines, and obligations and use maximum values for incremental when product demands or manufacturing capabilities are significantly different between periods. Users can tailor the batch modes, including ships, barges, railcars and trucks. Batch number and duration of each period, while a cloning feature transportation modes can be structured for single or multiple replicating data from any existing time period simplifies data entry compartments with different material loading configurations. for multi-period models. Model transportation costs based on the World scale system, on distance, point-to-point transfers, or complicated multiple User-defined constraints Define continuous and integer variables and enter user-defined destination trips. Fixed and time-dependent port-related fees can equations into the matrix structure using existing variables and also be included. user-created variables. This allows accurate modelling of realistic physical and economic constraints. Operations & Blending Any production or blending operation and associated costs can Proven results be easily modeled, including conversion of any material or group SAND cuts the costs and increases the efficiency and reliability of materials into other materials. Multiple modes of operation can of the supply chain management system. SAND: Simplifying Supply Chain Management with Better Supply and Distribution 3 Data management Use of MS Access’s standard relational database management system provides a single source of up-to-date supply chain data to users throughout the organization, preventing data being scattered throughout the corporation. The relational database features of MS Access also ensure data integrity, requiring, for instance, all necessary fields be entered before allowing users to save data records and preventing duplicate entries. When an object is deleted, the cascade delete feature of Access deletes all occurrences in all other data input and output tables as well. Both importing and manually entering data is simple with time saving features, and in-built flexibility in SAND allows temporary changes to the model structure to be simply handled. Powerful outputs SAND massively simplifies supply chain planning, with optimized Flexible reporting to record improvements results for each part of the value chain: • Raw material allocation plans Output from Crystal Reports can be exported to a variety of other • Production plans media, including MS-EXCEL or Lotus spreadsheets, Word • Product allocation plans documents, other text formats, any other ODBC compliant • Route and material loading plans databases, and HTML formats. • Exchange agreement plans. Benefits Economically optimized targets feed scheduling systems. SAND converts optimized distribution plans into implementable SAND brings a range of benefits to supply chain management for a more efficient business: schedules, taking account of transport availability and inventory • Reduced operation and transportation costs conditions. It makes batch size and sequence decisions for continuous transport modes such as pipelines and also makes • Enhanced demand-driven purchasing decisions taking into account realistic system limitations route selection and material loading decisions. • Improved customer delivery performance • Better inventory management control Custom, automated reporting Standard reports through Crystal Reports provide clear • Faster delivery cycles overviews of results such as penalties and the total amount of • More effective utilization of constraining resources materials transported by each mode. MS Access or any other • Enhanced and more up-to-date information for decisions. third party reports can be used to create custom reports. For More Information Learn more about how Honeywell’s SAND, visit our website www.honeywellprocess.com or contact your Honeywell account manager. Honeywell Process Solutions Honeywell 1250 West Sam Houston Parkway South Houston, TX 77042 Honeywell House, Arlington Business Park Bracknell, Berkshire, England RG12 1EB Shanghai City Centre, 100 Junyi Road Shanghai, China 20051 www.honeywellprocess.com PN-13-38-ENG July 2013 © 2013 Honeywell International Inc.