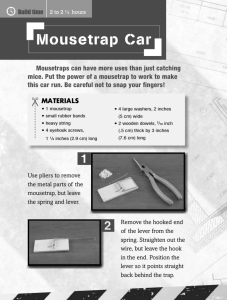

9 BACKGROUND INFORMATION Designing a Car for Distance?

advertisement

BACKGROUND INFORMATION Designing a Car for Distance? If you are trying to build a long distance travelling vehicle you will need to think carefully about the following concepts: Energy, Power Output, Inertia, rotational inertia, friction, torque and pulling force. Energy is what moves your vehicle. Energy starts as what is known as potential energy as the spring is wound-up, but as the spring releases its energy the energy changes to kinetic energy or energy of motion. Along the way energy is lost to the surroundings in the form of work (heat and sound. The idea is to reduce the amount of energy that is lost over a long distance which will extend the travel distance. Power Output is how quickly the energy stored in the mousetrap is released. There are really only two approaches to consider when building your vehicle for distance: 1. Build a fast moving car that releases its energy quickly and then coast as far as possible. 2. Build a slow moving car that releases its energy slowly over the entire pulling distance, this type of car will not coast very far. Inertia is the resistance that an object has to a change in it state of motion, the more inertia an object has the more force that will be required to change is state of motion. A heavy car will require more pulling force than a lighter car for equal acceleration; therefore, lighter cars will be easier to accelerate but ideally will have less coasting distance that a heavy car at the same speed. Rotational inertia is the resistance that a wheel or rotation object has to changing its state of rotation. Similar to inertia but dealing with a rotating object. The less rotational inertia that an object (wheel) has less the torque that will be needed to change its state of rotation or the easier it will it will be to accelerate. There are two types of friction, surface friction and fluid friction. Surface friction is caused by the rubbing of two surfaces in contact with one another. Where your axle connects to the frame of your vehicle is one place that you will find surface friction on your car. By reducing the surface friction with graphite powered or ball bearings you will see an increased performance with you vehicle. Traction is a wanted surface friction that it between your vehicle’s wheels and the flooring, increasing your tracking will allow for greater accelerations because it will take more torque to make the wheels spin out or break loose. Fluid friction is caused by an object trying to move the air out of the way. Make your car aerodynamic so that it is easier to push the air aside. Torque depends on the length of your mouse trap car’s lever arm and the strength of the mousetrap’s spring. A long lever arm has the same torque as a shorter arm. The difference between a long lever arm and a short lever arm is that you get more pulling force with a short arm than a long arm. To maximize your acceleration you want a shorter lever arm. Keep in mind that if your arm is too short the force will be large enough to cause the wheels to spin-out, wasting energy. To minimize you acceleration you will want a longer lever arm. Slow Moving vs Fast Moving Vehicle Here are my thoughts on the ultimate distance vehicle. In sharing my thoughts with you please understand that I am not telling you how to build the perfect Distance Car but I am point out the application of physics as I applied it to my mousetrap powered vehicles. I tend to design my distance cars to travel extremely slow. One of my cars that travels 100 metres or more may take over 5 minutes to travel that distance. My idea is to reduce the power output to a minimum, only supplying enough energy to the vehicle to overcome the friction. By travelling slowly you will reduce the air resistance to a minimum vs. a fast travelling car that will have more air friction acting against it. Also, I feel that a quick accelerating car will create more heat energy during a quick acceleration than a slow accelerating vehicle which will reduce the energy needed to travel a great distance. Building a mousetrap car for distance means minimizing the wasted energy. With that in mind, I like to build cars that have very low frictional forces acting against them and move slowly. I try to find a harmonious balance between the movement of my vehicle and the length of the lever arm. My cars tend to have long lever arms and large wheels. If a lever is too long the vehicle will not travel the full distance because you must have enough torque to keep the car going and the torque changes with spring angle. 9 WORLD RECORD CARS Common Design Problems, Tricks and Tips Answered PROBLEM: mousetrap car stops too soon. EXPLANATION: Most likely the answer is one of the following: there is too much friction at the bearing points or there is not enough pulling force. Try the following to correct the problem: 1. There may be too much friction at the rolling points between the axle and the frame. Try re-doing the axleframe points by making the axle holes larger, by adding graphite powder, or by using ball bearings. Ball bearings and axle must be selected to match each other. A hole is drilled large enough to hold the bearing in the frame, the axle will then fit through the bearing. (Tip: soak bearings in WD-40 to remove any grease residue) 10 2. There may not be enough tension in the pulling string. Move the mousetrap closer to the drive axle and adjust the string attachment point on the lever arm accordingly. Longer lever arms have less pulling force or try to build up the drive axle with tape to increase the drive ratio so the mousetrap can pull the vehicle easier. Lastly, test different mousetraps in order to find the strongest spring. PROBLEM: mousetrap car does not start or moves slowly. EXPLANATION: Most likely the answer is one of the following: there is too much friction at the bearing points or there is not enough pulling force. Try the following to correct the problem: 1. There may be too much friction at the rolling points between the axle and the frame. Try re-doing the axleframe points by making the axle holes larger, by adding graphite powder, or by using ball bearings. Ball bearings and axle must be selected to match each other. A hole is drilled large enough to hold the bearing in the frame, the axle will then fit through the bearing. (Tip: soak bearings in WD-40 to remove any grease residue) 2. There may not be enough tension in the pulling string. Move the mouse trap closer to the drive axle and adjust the string attachment point on the lever arm accordingly, longer lever arms have less pulling force or try to build up the drive axle with tape to increase the drive ratio so the mousetrap can pull the vehicle easier. Lastly, test different mousetraps in order to find the strongest spring. PROBLEM: My axle slides back and forth causing wheels to rub against the frame of the car, slowing or stopping the car. Try the following to correct the problem: 1. Adjust trust washer between wheels and the frame for a smoother rubbing surface with less friction. Try using flat metal washers as a thrust bearing, you can always use several washers if one is not enough, also use a little graphite powder on the thrust bearing. 2. Make spacers out of brass tubing to hold the wheels in place and limit the side-toside play of the wheels or axles. 3. If you are using bearings, the axle may be moving side to side. Carefully, glue the axles to the bearings without getting glue in the bearings. PROBLEM: Where should I mount the mousetrap? Here is your answer: It really depends on how you are designing your vehicle. If you want speed or power then you want to mount the mousetrap close to the drive axle so that you have more pulling force. Remember, your lever arm should only be long enough to reach the drive axle when fully wound-up. If the mousetrap is placed too close to the drive axle the force may be so great that the wheels spin out. If you are building a mouse trap vehicle for distance then you want as long a lever arm as possible that will put the vehicle the greatest distance, that means you will need to mount the 11 mousetrap as far as possible from the drive axle. Careful, if the mousetrap is mounted too far the pulling force will be too small to pull the vehicle. Make sure that your lever arm falls directly above the drive axle. If it does not, you should adjust the mounting position of the mousetrap or change the lever length. mousetrap racer propulsion DESCRIPTION: A mousetrap car is powered by the energy of a wound up mouse-trap’s spring. The most basic design is as follows: One end of a string is attached to the end of a lever arm that is attached to the mousetrap's "snapper". The other end of the string has a small loop that is designed to catch a hook attached to the drive axle. As the drive axle is turned, the string catches the hook and winds around the axle, the mousetraps "snapper" arm is pulled towards the drive axle causing the mousetraps spring to be wound. Once the mouse-trap’s is released, the string is pulled off the drive axle causing the drive axle and the wheels to rotate. A string is attached to the mousetrap's lever arm and them attached to the drive axle. Notice that the string has a loop tied at the axle end. This loop is caught by a hook on the axle so that the string is attached to the axle BUT it is allowed to release itself after the pulling force is spent. It is important to have the hook on the axle or the string will simple slip of the axle with out propelling the vehicle. Keep in mind that the hook must be short or it will re-catch the string and cause the car to stop. Wind the wheels in the direction opposite to the motion that you want the mouse trap car to travel, this will wind the string around the axle. Do not to wind the string loosely or it will snag itself. Do not push on the mousetrap's lever arm during this process you want the string to be tight and to pull the lever arm over. Once the car is released, the string is pulled off the axle it causes the wheels to rotate propelling the vehicle. If the mousetrap is located to close to the drive axle the wheels can spin at the start wasting energy. If the mousetrap is located too far from the drive axle there will not be enough pulling force to propel the racer to the finish. It is important to try the mouse trap in several locations from the drive axle in order to find your racers best performance. 12 Question: How long should my lever are be? Here is your answer: It really depends on how you are designing your vehicles. If you want to speed or power then you want as short a lever arm as possible before the wheels begin to spin-out. The shorter the lever arm the more pulling force delivered to the drive axle. If you are building a mouse trap vehicle for distance then you want as long a lever arm as possible that will put the vehicle the complete distance. By changing the length of the lever you change the pulling force, longer lever arms have less pulling force than smaller lever arms. Where you mount the mousetrap is just as important as the length of the lever arm. Where you mount the mousetrap and how long you make the lever arm really go hand-in-hand. The lever arm should only be long enough to ‘just’ reach the drive axle when full wound up. Make sure that your lever arm falls directly above the drive axle. If it does not, you should adjust the mounting position of the mouse trap or change the lever length Changing the lever is essential in order to build a mousetrap powered racer. In order to adjust the pulling force you have to extend the lever to the desired length. After the lever arm is removed a new lever can be attached and the length adjusted. Longer lever arms have less pulling force than shorter arms. Try the following: The lever arm is removed by cutting the corner of the snapper. The snapper is cut on the corner where the spring is wrapped over. The remaining snapper can be remove and replace with a bent rod, or a 1/8 inch brass tube can be pushed over the remaining snapper arm. Adjustable Steering As simple as it sound the reason that cars do not travel straight is because the wheels are not pointing the same direction. The solution is to be able to adjust the steering and bring the wheels into alignment if the vehicle is not travelling straight. Try the following: It is best to build a car that has adjustable steering so you can make adjustments to your vehicle when needed. The easiest technique is to build a swivel base that can be glued to the front of the mousetrap car. These pictures might show you how to build a swivel base, you will have to modify for your own vehicle. 13 Rotational Inertia and Mousetrap Cars Just as an object at rest tends to stay at rest and an object in motion tends to stay in motion, an object rotating about an axis tends to remain rotating about the same axis unless an external force or torque acts on it. The property of an object to resist changes in its rotational state of motion is called rotational inertia and is a restatement of Newton’s First Law of Motion. Rotational inertia is the resistance an object has to changes in rotation. Just as inertia for linear motion depends on the mass of an object, so does rotational inertia. But rotational inertia also depends on one more element—the location of the mass with respect to the axis of rotation. The greater the distance between the bulk of an object’s mass and its axis of rotation, the greater the rotational inertia. This principle is employed by a weightlifter when he or she twists a barbell with mass located on the ends. When the mass of the barbell is far from the axis of rotation, (i.e., its midpoint), the bar has considerable rotational inertia and is hard to turn or twist. If the mass is placed closer to the centre of rotation, the bar twists with less effort. It follows that the greater the rotational inertia of an object, the harder it is to change the rotational state of that object. If rotating, it is difficult to stop; if at rest, it is difficult to rotate. Question: I want to know if momentum is applied to a mousetrap raced? Answer: Momentum is mass in motion. With a mousetrap racer, the momentum is equal to the velocity of the mousetrap vehicle times the mass of the vehicle. Ideally, the faster a mousetrap vehicle is moving the more momentum it will have the further it will go, the only problem with that is we are forgetting about friction and energy. The faster you go with air friction, the more friction acts against the vehicle. Travelling straight Question: My car goes straight if i push it, but when i set it off with the mousetrap it travels to the left. I built a small car made with wheels from an old toy and the wheels do move a little to the left and right if pushed. if this is what's causing the turning then do you have any suggestions on how to make my wheels sturdy but still able to spin? Answer: Travelling straight has everything to do with the alignment of the axles. If the front and rear axle are not aligned parallel then a vehicle will drift in one direction. If the vehicle travels straight when you push it but then travels crocked when the mousetrap is pulling on the drive axle, the problem is with one of the holes holding the drive axle to the frame. One of the holes on one of the sides of the frame is stretched out so that the axle is crooked when the mousetrap pulls on the axle but causes the axle to sit straight when the mousetrap no longer pulls on the axle. CHECK THE DRIVE AXLE HOLES Pulley System Question: Exactly how does the pulley system work? Answer: Pulley system is set-up so that there is one large pulley wheel that is turned by the mousetrap's lever arm and there is a smaller pulley on the drive axle that is turned by the large pulley, for every rotation of the large pulley, the drive axle is set to make 10-20 times the turns -- in the end, the vehicle is pulled over a much greater distance because of the ratio of the gearing and without having to use a super large drive wheel on many older distance cars. This system is much simpler to make that the old fashion big wheel cars. 14 Lever Arms Question: What make the best lever? Answer: There is never one right answer. It always depends on the type of vehicle you are building. You want to use a lever arm system that does not bend a lot and this will depend on how long your lever arm is. In some situations, a lever arm will work perfectly without bending but if the lever arm is made too long it will bend and you will not get maximum starting energy. In some situations you if you need a long lever it is best to make one from two long pieces of wood put together into a "T". This is a very strong stet-up that works great with really long lever arm systems. Coat hangers do NOT make good lever arms, they really tend to bend way too much so you lose a lot of your starting energy. Keep in mind that a BIG chunk of energy comes from the last bit of being able to fully compress the mousetrap spring 180 degrees. Making a mousetrap racer travel further Longer lever arms. The more string that can be pulled off the drive axle translates into more turns that the wheels can make, this causes your vehicle to cover more distance under the pulling force. Large Drive Wheel(s). Large drive wheels cover more linear distance for each rotation than a smaller diameter wheel. The best wheels tend to be between 1-2 feet in diameter. Small Drive Axle. You can get more turns with a smaller axle for the same length of string than with a larger one. More turns of the axle means more turns of the wheel, which means greater travel distance. Small Power Output. Vehicles that move slower tend to be more energy efficient in comparison to an equally built car of same rolling friction. You can slow a car down by increasing the lever arm length and repositioning the mousetrap further from the drive axle. At low speeds, air resistance is not a large factor in the motion of a moving object, but as the speed of an object increases, the force of air resistance also increases; therefore, at higher speeds moving objects will have to expend more energy to maintain constant velocity. For this reason, it is best to build a slow moving distance car! Decrease Mass and Rotational Inertia. Build a lightweight frame and use lightweight wheels. Remove mass from wheels to decrease rotational inertia. Sample Different Mousetraps. Not all mousetrap springs have the same spring tension. The greater the tension in a mousetrap, the more energy you will be able to store when the spring is wound-up. Remove ALL Friction. This one is impossible but the more you can reduce friction, the less energy that will be lost to heat and sound which translates into greater travel distance. Your vehicle should have the lowest possible energy consumption; this means that your vehicle should be a slow mover and use ball bearings. Using these principles, mousetrap cars have travelled 100+ meters! 15 Mousetrap Projects and Torque When you turn a water faucet, open a door, or tighten a nut with a wrench, you exert a turning force called a torque. Torque is the rotational counterpart of force. You apply a force to make an object move or accelerate in a particular direction. You apply a torque to make an object turn or rotate. A torque is produced when a force is exerted with leverage. For example, a doorknob is on the opposite side of the door from the hinges in order to increase the leverage. By placing the doorknob far from the turning axis of the hinges, less force is required when you push or pull on the doorknob. Less effort is required to use a long wrench than a short wrench to loosen a nut because you have more leverage with a long handle. The distance from the turning axis to the point of contact is called the lever arm when the force is applied perpendicularly. Therefore, torque is the product of the lever arm and the force that tends to produce rotation. It is important to note the direction of your applied force. You push or pull the doorknob perpendicular to the plane of the door. The key to a quick start is the proper relationship between the tension on the string and the grip friction of the tires. If the pulling force on the string is too large, the tires will spin at the start, wasting the spring’s energy and thus decreasing performance. The tension of the pulling string should be at its maximum for a speed vehicle but not large enough to cause the wheels to spin off the start. By adjusting the length of the mousetrap’s lever arm, you can vary the force that is applied to the wheels of your car. Long lever arms decrease the pulling force while short arms increase the pulling force. Mousetrap Racers and Friction This article explains friction and how to exploit it to create great mousetrap racers. A ball rolling across the floor will eventually slows to a stop. The reason the ball slows to a stop is because of friction. Friction is a force that always opposes motion in a direction that is opposite to the motion of the object. An object sliding to the right experiences a force of friction towards the left. If it was not for friction, an object would roll or move forever, as long as there was nothing—like a wall—to stop its motion. Your mousetrap car is affected by friction in the same way as a rolling ball, friction acts against the motion of the moving ball and will slow it to a stop. Friction occurs anytime two surfaces slip, slide, or move against one another. There are two basic types of friction—surface friction and fluid friction. In some situations fluid friction is called air resistance. A ball falling through the air is affected by fluid friction, and a block sliding on a table is mainly affected by surface friction as well as a little air resistance. The greater the amount of friction between two surfaces the larger the force that will be required to keep an object moving. In order to overcome friction, a constant force is needed. In order to maintain a constant force, there must be a supply of energy. A ball which is given an initial push will roll until all its energy is consumed by friction, at which point it will roll to a stop. The smaller the forces of friction acting against a moving object (like a ball or mouse-trap car), the farther it will travel on its available energy supply. Eliminating all forms of friction is the key to success no matter what type of vehicle you are building. Surface friction occurs between any two surfaces that touch or rub against one another. The cause of surface friction is mutual contact of irregularities between the touching surfaces. The irregularities act as obstructions to motion. Even surfaces that appear to be very smooth are irregular when viewed microscopically. Luckily, during motion surface friction is unaffected by the relative speed of an object; even though the speed of an object may increase, the force of surface friction will remain constant. This means that the same force is required to slide an object at a slow or fast rate of speed on a given surface. The amount of friction acting between two surfaces depends on the kinds of material from which the two surfaces are made and how hard the surfaces are pressed together. Ice is more slippery than concrete; therefore, ice has less friction or less resistance to slippage. A heavier brick is harder to push and has more friction than a lighter brick only because the heavier brick pushes into the ground with more force or weight. 16 Minimizing surface friction on a mousetrap car allows its wheels to spin with less resistance, resulting in a car that travels faster, farther and wastes less energy. The most common area where surface friction will occur is between the axle and the chassis. Friction is not restricted to solids sliding over one another, friction also occurs in liquids and gases, collectively called fluids. Just as the friction between surface friction depends on the nature of the surfaces, fluid friction depends on the nature of the fluid. For example, friction is greater in water than it is in air. But unlike the surface friction, fluid friction depends on speed and area of contact. This makes sense, for the amount of fluid pushed aside by a boat or airplane depends on the size and the shape of the craft. A slow-moving boat or airplane encounters less friction than fast-moving boats or airplanes. Wide boats and airplanes must push aside more fluid than narrower crafts. If the flow of fluid is relatively smooth, the friction force is approximately proportional to the speed of the object. Above a critical speed this simple proportion breaks down as fluid flow becomes erratic and friction increases dramatically. The amount of air friction or fluid friction depends on the speed and the shape of a moving object. The faster an object moves, the more collisions that occur with particles of the fluid, causing increased friction. The shape of a moving object, its aerodynamic, determines the ease of flow of the fluid around the moving object. Fast cars are designed and shaped to cut through the air with less friction so they can move faster. Trucks have a special cowling that increases their aerodynamics and allows air to flow more easily over the trailer. Increased aerodynamics saves energy. Fish have aerodynamic shapes that allow them to move through the water with less effort. Keep in mind that there are situations in which you would want to increase the air resistance. A good example is the use of a parachute on a dragster to help it stop the vehicle or the flaps on an airplane to help slow it down. Because the force of air resistance increases as the speed of an object increases, faster moving mouse-trap cars will have more air resistance acting against them, causing them to use more energy and come to rest sooner than a similarly built slower-moving mouse-trap car. Keeping this in mind, good aerodynamics will improve performance of any vehicle, no matter what type of car you are building. This means that your car must be smooth with few points of air drag. Inspect the body for flat surfaces on leading edges that could catch air, thus increasing the air drag. Rounding the leading edges of your vehicle will allow for smoother movement of air around your vehicle. Cars made from wood need to be sanded smooth. Sanding will remove any unwanted irregularities, thus decreasing the force of air resistance acting on your car once it is in motion. Tires should be thin. Thin tires are more aerodynamic and slice through the air more smoothly. Wider tires will have more air drag than narrower tires. Therefore, try to pick thin tires when you are building your mousetrap car. Friction is not always a bad thing. Without friction you could not move anywhere. As you walk forward, it is the friction on the bottom of your feet that allows for the grip you need to move. It is the friction between the road and your tires that keeps the wheels from slipping and allows your vehicle to move. This type of friction is called traction and is a desired form of friction. What type of wheels work best: fat tires, thin tires, knobby tires, or smooth tires? Knobby tires have good traction if the road surface is rough, but the trade off is that they are inefficient and use more energy than smooth wheels. When pressure is placed directly on a knob, more force compresses the tire causing the rubber and air inside the tire to heat up. The energy it takes to compress the rubber and air in the tire is lost as heat. Knobby tires become hotter with continued use. Racecars use smooth tires called slicks. Smooth wheels will be more energy efficient and allow a car to travel faster. On mousetrap cars, smooth tires will allow a vehicle to travel a longer distance. 17 Wheels and Axles - the gearing of your racer Changing the diameter of either the wheel(s) or the axle controls the mechanical advantage of a wheel-axle system. When the ratios of the length of string used per turn divided by the distance travelled is less than one, the mechanical advantage is small and the car travels slow and far. When the ratios of the length of string used per turn divided by the distance travelled is greater than one, the car accelerates very quickly and uses only a small amount of string. The diameters of your drive wheel and drive axle represent your gearing or transmission. A transmission is any device that transmits mechanical energy from one place to another. With a mousetrap car, power is transferred to the wheels via a string wrapped around a drive axle. The ratio of the drive axle to the drive wheel represents the gearing of the vehicles or the transmission. If you place your mousetrap vehicle on the ground and the vehicle does not start to move or it starts to move but then stops part of the way through its motion, the vehicle does not have enough pulling torque and/or the vehicles axle-to-wheel ratio is too large. If you do not have enough torque you should increase the mechanical advantage of the system by doing one of the following: • shorten the length of the lever arm • using a smaller diameter drive wheels, or • make the drive axle thicker by wrapping tape around the axle (The tips from above can also be used to increase the speed of a racer) The larger the diameter of the driven gear or pulley, the greater the mechanical advantage or torque. By increasing or decreasing the wheel-to-axle ratio, you will change the mechanical advantage of your mousetrap car. Keep in mind, changing the mechanical advantage does not increase the work you get from your mousetrap; it only changes the size of the force and the distance the force is applied. With distance vehicles, you want a small force over a long distance; therefore, use a large wheel with a small axle (i.e., a large wheel-to-axle ratio). A large wheel with a small axle will cover more distance per each turn of the axle when compared to a smaller wheel with the same axle. There is a trade-off for having a large wheel-to-axle ratio. The trade-off is that it takes more force to accelerate the vehicle to the same speed in the same time as a vehicle that has a small wheel-to-axle ratio, but this is okay because distance cars should not be fast in order to cut down on air resistance. It is essential that a vehicle with a large wheel-to-axle ratio has a small rotational inertia wheel, since low rotational inertia wheels will be much easier to rotate than large rotational inertia wheels. Making a long distance mousetrap vehicle When you build a mousetrap car for distance, you want small energy consumption per second or a small power output. Smaller power outputs will produce less wasted energy and have greater efficiency. You can change the power ratio of your vehicle by changing one or all of the following: where the length of the mousetrap's lever arm, the drive wheel to drive axle ratio. The amount of energy released by using a short lever arm or a long lever arm is the same, but the length of the lever arm will determine the rate at which the energy is released and this is called the power output. Long lever arms decrease the pulling force and power output but increase the pulling distance. Short lever arms increase the pulling force and the power output by decrease the pulling distance but increasing the speed. If you are building a distance vehicle, you want to minimize the power output or the transfer of stored potential energy into kinetic energy of motion at the slowest possible rate. This usually means having a long lever arm and a large axle-to-wheel ratio. If you make the lever arm too long, you may not have enough torque through the entire pulling distance to keep the vehicle moving, in which case you will have to attach the string to a lower point or change the axle-to wheel ratio. Most important is reducing friction, the more you can reduce or eliminate friction, the farther your racer will travel. In a perfect universe, a mousetrap vehicle will travel forever, just like an object thrown in space should travel forever or until it hits something. This is the challenge that makes building mouse trap powered cars so much fun, seeing who can reduce friction the most. 18 Greater distance can be achieved by: • using a longer length lever arm • having a large axle to large wheel ratio. • eliminate friction Slow Moving vs. Fast Moving Vehicle. Here are my thoughts on the ultimate distance vehicle. In sharing my thoughts with you please understand that I am not telling you how to build the perfect Distance Car but I am pointing out the application of physics as I applied it to my mousetrap powered vehicles. I tend to design my distance cars to travel extremely slow. One of my cars that travels 100 meters or more may take over 5 minutes to travel that distance. My idea is to reduce the power output to a minimum, only supplying enough energy to the vehicle to overcome the friction. By travelling slowly you will reduce the air resistance to a minimum vs. a fast travelling car that will have more air friction acting against it. Also, I feel that a quick accelerating car will create more heat energy during a quick acceleration than a slow accelerating vehicle which will reduce the energy needed to travel a great distance. Building a mousetrap car for distance means minimizing the wasted energy and converting more energy into displacement of the vehicle. With that in mind, I like to build cars that have very low frictional forces acting against them and are slow moving. I try to find a harmonious balance between the movement of my vehicle and the length of the lever arm. My cars tend to have long lever arms and large wheels. If a lever arm is too long the vehicle will not travel the full distance because you must have enough torque to keep the car going and the torque changes with spring angle. 19