Better Appliances - ASAP Appliance Standard Awareness Project

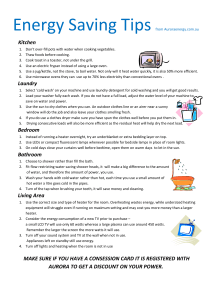

advertisement