Maintaining Excellence Through Change

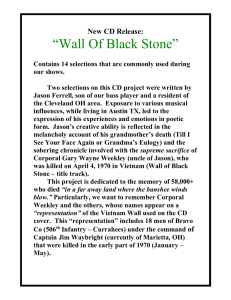

advertisement

Workshop Report: Maintaining Excellence Through Change Employee involvement, a Material As Needed (MAN) system, and statistical operator control are among the steps toward competitive excellence at Harley-Davidson Motor Company's York, PA plant. Accounting changes and revved-up partnerships with suppliers and motor carriers also support the transition to continuous flow operations. John A. Saathoff n 1987, Harley-Davidson became one of the heroes of American Imanufacturing. Two events marked this happening. First, the company visited Washington to request that the tariff on large Japanese motorcycles', imposed in 1983 by the International Trade Commission (ITC), be lifted a year early. The ITC was told, "We no longer need tariff relief to compete with the Japanese." Second, President Reagan visited the York, PA plant to applaud Harley's turnaround and spotlight it as an example of what is possible in American manufacturing. Twenty years ago, HarleyDavidson, whose name had been synonymous with heavyweight motorcycles, held an estimated 80 percent share of the market segment above 850cc displacement. By 1982, that share had nosedived to 20 percent. The Japanese had become a major force in motorcycles. Honda had opened its Marysville, OH plant in 1979. Corporate pressure for high unit volume, coupled with inadequate design and production systems, took a severe toll on quality and worker attitudes. According to York management, Harley found itseif producing over-priced, low-quality products, while competing directly with the Japanese, who were doing just the opposite. Harley began changing its marketing and capital structure, while focusing on quality and workers' suggestions, Spring 1989 JIT Results at Harley-Davidson • 49 percent overail productivity increase • 75 percent overall setup reduction • Inventory turns up from 5 to 20 • 60 percent reduction in WIP and raw material • 65 percent decrease in scrap and rework • 35 percent decrease in warranty costs • 35 percent reduction in warehouse space • 26 percent reduction in plant space • 50 percent fewer suppliers Fig. 1. but the 1982 recession nearly finished them off. Today, Harley's share of the heavyweight market is 45 percent and climbing. On September 12 and 13, the company hosted an AME workshop to share its ideas for manufacturing excellence. Also on the agenda were a tour of the York, PA plant and feedback by the visitors regarding Harley's perceived strengths and opportunities for improvement. "Change-How, When, What" was Harley-Davidson's workshop theme. "One hears a lot of buzzwords," warned Bob Miller, general manager of Harley's York, PA fabrication and final assembly plant. "But none of them will work for you unless you know how to manage change, which becomes even more difficult as the market improves and profitability picks up." Management of change at Harley-Davidson is based on three interacting "tools for change:" Employee Involvement, Material As Needed, and Statistical Operator Control. All three of them were put in motion before other programs were started. Employee Involvement The use of employee assets to C> 13 Concepts To Manage In The 80s Employee Involvement Materials As Needed Statistical Operator Control Fig. 2. Management of change at Harley-Davidson is based on three interacting tools for change: Employee Involvement (EI). Material As Needed (MAN). and Statistical Operator Control (SOC). All three tools were put in motion belore other programs were started. Among the EI basics: Employees learn how to recognize and eliminate waste, a key to continuous improvement. Fig. 3. Quality circle members work together to solve problems at Harley-Davidson's York, PA plant. 14 improve quality and productivity is understood and applied in 3 percent to 5 percent of U.S. companies. Harley estimates that 95 percent to 98 percent of Japanese companies operate with this concept. The company's goal is to link teams in a company-wide network. It understands more now about how to train operators while letting groups know what is expected of them. "We strive for an Employee Involvement (EI) Program that is as individual and unique as the members of the organization," states Anne Thundercloud, York plant Quality Circle facilitator. It is the Harley employees who make J IT work, by having an investment in seeing it work. The facilitator's job in this environment is to help connect the employees. "The key to continuous improvement is helping employees learn how to recognize and eliminate waste." says Don Lefever, York plant materials manager. Employees are seen as links in a chain. By continuing to strengthen the chain, employees increasingly drive quality throughout the organization. In Harley's industrial reiations environment. EI also provides a formal mechanism whereby employees can influence the quality of work life. The company continually reinforces its commitment that employees will participate in discussions and deci· sions on changes which affect them. Problems and solutions are often seen by workers on the line before management sees them. Therefore, management is convinced of the payoff from asking workers what they think. Among the forms of Employee Involvement at Harley are: • Quality Circles • Preventive maintenance • Setup reduction • Value Analysis • Statistical Operator Control. Management appears to be acutely aware of the high mortality rate among productivity and cost containment programs. Much of the problem can be traced to poor communication. lessening enthusiasm, and a lack of reward and recog ni - Target Production Flow Based On Consumption Raw Material Storage ~~~ I t Raw material ordered via raw material card Raw material delivered , ,..... 'P' cards Board 118-31 Board F36-11 ~ Machine F36-11 -/ tP 'P' cards Board E39-21 ~ ~ ~ , WIP tP ~ ~ ~ ~ ~ Machine 118-31 'P' cards WIP Machine E39-21 Board G19-43 Finished P arts Place in master location for consu mption 100 PCS./de dicated container - '-./ '-./ WIP tP I I I Machine G19-43 tP Location SF 20-3 -------- - - - - ... P P P I I I 1- [;]~: 11001 100 p p P I I 100 J-~ B~: WIP ./ I I I I p I B: 100 - - - - - - - - ____ ..J Production card is returned to 1st operation MAN board 118-31 signaling consumption of one card quantity. -------- I M M I I :~B: Move card replaces the production card and full container is returned to the point of consumption. I I M I :I 1100 L_ I __ : Empty container with card goes to issue from master location SF20-3. I _J Fig. 4. Starting with the principles of the Kanban system developed at Toyota, Harley devised MAN (Material As Needed) to replace MRP (Material Requirements Planning) and gain visual control of the production and movement of parts. Key features of Harley's system: MAN boards at each machine hold production cards for the next lot to be run. Cards, released as parts are consumed, represent the authorized number of standard containers in WIP (work in process) and finished stock. tion. EI has evidently been the most important as well as the most difficult to implement of the three "tools for change." Harley succeeded by continuously buiiding top-down commitment, trust, and cooperation, and by learning how to surrender some of management's traditional authority. Material As Needed Harley's Just-In-Time (JIT) manufacturing system is called Material Spring 1989 as Needed (MAN). It was developed in 1982 with the primary goal of improving quality. Trends in the automotive industry toward JIT delivery of purchased parts, reducing inventory and releasing capital, strongly influenced the MAN system design. An implementation team was formed of six salaried and four hourly personnel. Prior to 1982, Harley suffered from chronic parts shortages. By one estimate, fewer than 70 percent of motorcycles were complete off the end of the assembly line. Vehicles missing parts littered the shop floor. Motorcycle production was often based on parts availability rather 'than the master schedule. Gaining control of parts became an important objective, with parts manufactured in-house as the first point of attack. By developing a system that would put parts control directly on the shop floor, the implementation team knew it would also improve parts quality. The team reasoned that inventories produced before they are needed by the next operation are likely to deteriorate I> 15 from storage and handling. Obsolescence. engineering change, and hidden defects all impact high Inventories to a greater extent than they do parts produced as required. In view of the source of the competitive threat, together with the similarities between motorcycle and automobile manufacturing, the team chose the Toyota Production System as a guide, modifying it to meet Harley's requirements. Toyota's system focuses on the elimination of waste, in part by continually reducing the inventories that decouple the user of parts from the preceding operation. It is driven by Kanban, a visibie communications and controi system using circulating cards and standard containers. Kanban appeaied to Hariey because it puts real time production control information at the point of use on the shop floor, without requiring complex and costly resources for planning and support. Any major departure from "business as usual" requires that something be done. In the York plant, MAN was implemented first. The sole change to facilitate It was a move from batch lot motorcycle production to mixed model final assembly. This improved the labor balance at final assembly as well as smoothed production in upstream operations. MAN was designed to use the features of the York facility to best advantage. The location of each machine is identified by a shop floor address which corresponds with the coordinates of its adjacent support column. MAN cards are used to assign a sequence of dedicated machines to specific parts and specific operations, thus eliminating a major source of variability. By identifying both shop floor locations and machines, Harley set the stage to eliminate WIP warehousing and store reduced levels of manufactured parts on the shop floor. Finished parts are placed in one of several types of standard containers. The number of containers needed to meet the calculated supply (lot size plus demand during leadtime plus safety stock) determines the number of production cards in the system. The flow of raw material, parts, and MAN cards is illustrated in Fig. 4. The MAN system uses cards as the visible signal to produce or move something. Three kinds of cards are employed: 1. Raw material: Move raw material to machine when a job is triggered to be run. Signal the need to order raw material to replace the quantity used. 2. Product/on: Authorize production of parts via specified routing, and placement in designated storage area. 3. Move: Authorize movement of manufactured parts to a consuming area from their storage area. Having met its first priority, that is, to achieve control of parts production and flows, Harley could now see more clearly how to approach the next opportunities in setup reduction, preventive maintenance, statistical process controi, and group technology. Statistical Operator Control What is quaiity? Harley management believes that quality is different things to different people. Quality may be getting the right part at the right time, or in the right quantity, to print specifications. It may also be getting good products or service at a fair price. Statistical Operator Control (SOC) was management's response to lost market share and weakening financial position due to poor product quality, and high scrap and rework. The name (Statistical Operator Control) means that the operator can control the process with statistics. The operator is the key "ingredient," The charts are kept manually. a form of employee involvement. It is a way to personalize SPC. When each employee has the tools needed to control the quality of his or her output, employee involvement and quality at the source are linked. Attending a basic course of 40 hours, all employees receive the statistics training needed to "know where they are in any given continuous improvement cycle." The vice president and general manager was trained first. Training of others began in January 1984. The course is kept interesting and vitai by teachIng it on company time. The W. Edwards Deming video tapes are interspersed with classroom lectures and exercises. Homework assignments give each employee the opportunity to make a personal commitment. Today, suppliers are also being involved in the monthly statistics training courses. The SOC training program basics include: • Introduction to control charttheory • Introduction to attributes control chart • Introduction to variables control chart • Process capability • Problem solving • Uses/applications. Fig. 5. A bike is ridden an equivalent of two mites, when all functions of the vehicle are checked. 16 Target - Fig. 6. Harley's own fleet heuls 15 to 18 shipments each week from the Milwaukee engine piant to York, PA. Vendor Freight Consolidation Purchasing practices have changed at Harley since the early 1980s in order to capture the benefits of supplier partnerships. It was a natural progression from there to the analysis and improvement of the inbound logistics process. "Partners in Profit," states Tom Schwarz, general manager of Harley-Davidson Transportation Company, "describes our policy to establish long-term, successful vendor relationships; and that policy extends to our carrier network." The key developments in purchasing include: stabilizing 16week rolling schedules, single sourcing and supplier base reduction, more frequent deliveries in small quantities, and evaluation of suppliers on the criteria of manufacturing excellence instead of price alone. Some of these changes would have <ncreased inbound freight costs had the logistics process not been changed. Prior to 1984, Harley's analysis showed that inventory was turning 8 to 10 times per year. Inbound shipments of 2500 Ibs. or less comprised 85 percent of the total, and 38 percent were 400 Ibs. or less. Anticipating the impact of JIT plans, Harley expected that inventory turns would increase by a factor of three Spring 1989 to four. Harley felt that its inbound materials logistics processes were archaic, ineffective, and costly even for the demands of that era. Without fundamental change, the company could have absorbed neither the cost nor the confusion caused by escalating frequencies of shipments and receipts. Harley-Davidson found that the impact of high LTL (less than truckload) rates on small shipments over long distances could be offset through innovation in its transportation system. One aspect of this was implementing consolidation techniques with specialized motor carriers. Partnerships were as effective here as with suppliers of other kinds of services and materials. Partnerships with Motor CarriersKey Steps: • Reduce and stabilize the number of carriers used. • Focus purchasing power with the reduced carrier base. • Negotiate customized rates and realistic schedules. • Monitor on-time delivery performance. Successful long-term relationships with carners as partners mean that these carriers are interdependent with Harley's own truck fleet. The carriers are used interchangeably to move both inbound plant ma- terials and outbound finished goods to retail dealers. Tom Schwarz offers a word of caution. "If you are not ready to exercise the necessary forbearance that this commitment imposes, don't start," he says. Freight consolidation is handled in two modes. Which one depends on the supplier's distance from the York plant. For distances of 200 miles and greater, suppliers are instructed to ship via preferred carrier to consolidation centers at Aurora, IL and Cleveland, OH. The individual loads of 100 to 2000 Ibs. each are placed in a Harley consolidation trailer, which departs for the York plant on the same day each week. The cost of consolidating on-time deliveries to a regional center is borne by Harley. Failed shipments must be expedited by air freight at the supplier's expense. Within a 200 mile radius of York, inbound freight is moved via MANTRAN, which means Material As Needed Transportation. In this case, the truck, driven by a Harley employee, completes a daily "milk run" to a designated set of vendors on a pre-defined route. Some vendors are served weekly, some less frequently, and some more than once per week. Each vendor is expected to have his order staged on the dock at the agreed time in order to meet a 15-minute daily pickup window. Harley believes these circumstances to be ideal for the use of returnable containers. As with more distant vendors, Harley bears the costs of on-time pickup. Failed shipments must be expedited via surface carrier at the vendor's expense. Shipments in truckload (TL) volumes do occur. Harley's own fleet .hauls between 15 and 18 such shipments each week from the Milwaukee engine plant to York. Shipments of tires from Buffalo and inbound containers from offshore suppliers through the port of Baltimore are also moved in TL quantities. The Milwaukee material inciudes engines, transmissions, and plastic parts, all mounted in specially deC> 17 Vendor Consolidation Points for TL Shipments to York MN JA IN MO Fig. 7. Rather than receive costly frequent small shipments from distant suppliers, Harley-Davidson Transportation Company positions an empty traiier in its Aurora, IL and Cleveland, OH consolidation centers on the same day each week. The empty trailer Is exchanged for a full consolidated truck load containing one week's worth of supplier material for movement to York, PA. Tires are shipped from Buffafo, NY, and Baltimore, MD is the port of entry for materials purchased offshore. Deficiencies in Traditional Practices Needs from Modern Accounting • Encourage bUilding inventory with large lots and long runs • Encourage lower cost and improved quality • Too much attention to labor detail • Information available when it can be used to fix problems • Do not focus on material velocity • Simple system, easily understood • Do not encourage continous improvement • Responsive to market changes. Fig. 8. signed racks. In addition, this TL lane (motor carrier route) handles accumulated parts from Milwaukee's internal manufacturing centers, as weil as other parts from Milwaukeebased suppliers. The benefits Harley is realizing from these changes go beyond inbound freight cost reduction: • Consolidated shipments from 60 18 suppliers into two trucks, reducing delivery frequency at the York dock • Established outbound freight control from point of origin to two main regions. • Built on-time delivery improve,ment trend approaching "high 90s" • Provided advance warning of - and time to react to - missed shipments. Schwarz says he knows the contents of each trailer at 7 a.m. each morning through EDI (Electronic Data Interchange), linking the preferred carrier's mainframe computer to his office PC (personal computer). MAN Manufacturing Accounting As Harley-Davidson saw the impact of JIT practices on inventory, Target Continuous Improvement Measures • First-run acceptance • Vehicles per employee • Conversion cost/unit • Inventory days • Scrap cost/unit • Cycle time • Schedule stability Fig. 9. quality, and delivery, questions arose about the effectiveness and value of its cost accounting systems. The main issues were the cost of administering the system, the decision-making value of the information provided, and the actions encouraged by accounting measurements to reduce customer service, profitability, and inventory turnover. Instead of supporting the elimination of waste, Harley found, these measures encouraged its creation. For example, department efficiency measures could be improved by building inventory and by treating rework as earned direct labor hours. It was also found that administrative cost was a function of the degree of control required to measure performance of a complex manufacturing process. Significant changes in accounting philosophy and practices were precipitated by the changes in manufacturing organization and systems. As processes were simplified, visual controls could be substituted for detailed accounting controls. The first change, eliminating detailed labor reporting, was implemented in January 1988. Job cards were removed, labor classifications were combined, and iabor and overhead were combined into an account called conversion cost. Some 40 labor control codes that had Spring 1989 Success Factors • Management commitment. From the CEO down through division and plant management, the top leveis of Harley-Davidson speak and act with conviction about the new culture of continuous improvement, a rededication to quality, and true employee involvement. • Openness and morale. There is obvious pride displayed by many operators at York. These people were anxious to share their success with us, a fact that validates the commitment voiced by management. • Accounting changes. The simplification and alignment of controls and measures with world class manufacturing goals was seen as a "big plus." • Operator involvement and responsibility. Our tour guides identified strongly with the York organization. and spoke convincingly of their contribution to the problem solving process. • Material As Needed. Participants were struck by the simplicity and visibility of this system in the plant. together with the progress Harley is making in extending it upstream to suppliers. • Logistics. York is one of the best examples in the United States of how inbound transportation and material movement to the point of use should be redesigned as a process to support JIT manufacturing. • Work centers and cells. Big dividends are being realized by grouping similar processes and work teams. Less material movement, shorter cycle times, and a tighter quality focus are the most obvious ones. Fig. 10. been shown in the overhead statement were deieted. Cost center efficiency is no longer reported. The company feels that many individual actions to increase efficiency ran counter to the goals of the overall organization. Included were long runs that could not be absorbed by the subsequent operation. Now production credit is given for good completed units. This focuses group effort on completing vehicles and satisfying customers. More changes took place in July, this time to the Work In Process (WIP) system. WIP is now treated as a constant dollar number. Therefore, the need for transactions of cost in and out of WIP has been eliminated. Perpetual inventories are now back flushed, to update raw material and purchased part balances, when the vehicle is hung on the final assembly conveyor. While most measures are now based on daily actuals, a few variances are developed. These include purchase price variance and design change variance. The latter was implemented in response to manufacturing's request to relieve manufacturing at the current BOM cost. The design change variance is calculated by comparing the current and fro· zen BOMs. Harley-Davidson has found ways to "piggyback" on manufacturing data, reducing the incentive to find ways around a system often lacking in accuracy and timeliness. In simplifying the system, they identified some changes to measuring manufacturing performance. These changes were discussed during the workshop, which also included a tour of the York plant; operators served as capable guides. The frame shop, paint shop, subassembly, and final assembly areas received the most attention. The workshop concluded with small group discussions and presentations about strengths and opportunities to the York piant staff. (See Fig. 10). Plans for Further Improvement Beginning with its pilot efforts in late 1981, and staying the course through the 1982 collapse of the heavyweight motorcycle market, the York fabrication and final assembly plant has carried its fair share of the continuous improvement load at 19 Harley-Davidson. The specific needs of the York plant led it to work first on schedule stability, mixed model assembly, and a pull (MAN) system. York initiated employee involvement activities in 1982, followed by SPC (SOC) in all operations in 1983. Major revisions to change processes from batch to flow processing, begun at that time, are continuing as the focus of improvement today. According to Harley's Jeff Sipling, "Completely dropping batch processing and implementing flow process operation will cause each machining and fabrication center to be an extension of our assembly line." Since Kanban was implemented in a layout based on functional equipment areas (press shop, machine shops, welding, etc.), a new layout that supports production flow is needed. Harley has identified families of parts that require similar setups and manufacturing processes, and has determined what equipment is needed to produce these parts. The equipment is laid out in a work center for minimum run size and materials handling, and is located close to where the parts are consumed. Harley is moving towards paperless production. Some flow lines that include all operations in a cell are in place. More are planned. Returning dedicated containers will serve as the production authorization, eliminating the need for a system that uses multiple kanban cards. Continuous improvement is foreseen in purchasing as well. Harley's recent efforts here have involved implementing MAN at suppliers. A number of methods are used, including meetings with more advanced suppliers, on-site SPC training, supplier seminars, and a fulltime supplier assistance team. The ground work is being laid for bar coded supplier kanbans that would permit paperless shipping, receiving, and invoicing. Leveling schedules and providing firm information on requirements are two aspects. Also planned is a further reduction in the supplier base. Preference will be given to suppliers who share Harley's JIT philosophy. Nearly every aspect of JIT, EI, and SPC can be seen in some area of the York operation. Harley's management is first to observe that there is more to do. The discussionl feedback groups confirmed that opportunities exist in housekeeping, quality systems, pull system discipline, and performance measure visibility. Harley people speak of their awareness that change becomes more difficult to sustain as the market improves and profitability picks up. The rate of change demonstrated at York is the best evidence that Harley will successfully resist the temptation to become complacent. Author: John A. Saathoff is corporate director of materials management, Harris Corporation, Melbourne. FL.