Auto Components Sector

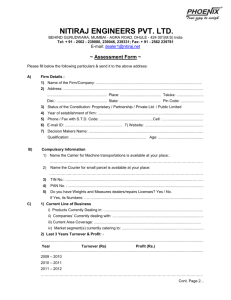

advertisement