Box Pushing in adverse condition after failure of bank RJT

advertisement

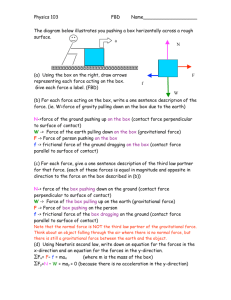

BOX PUSHING IN ADVERSE CONDITION PREPARED & PRESENT BY DINESH CHAND , SRDEN/HQ RAJKOT WR DURING ADVANCE BRIDGE & GENERAL COURSE COURSE NO.822 FROM 21.4.08 TO 16.5.08 AT IRIC EN PUNE Description of work Proposed Laying of Various Dia. of Petroleum Product M.S. Carrier Pipes through 3 X 2 X 7.50 X 2.20 R.C.C. Box under the Track at Km. 857/9-11 between Kanalus and Motikhavdi Stations for Reliance Petroleum Ltd. Jamnagar. In this work three segments of twin boxes having size 7.5m x2.35 m (internal dimension) were to be cast outside and then they are to be pushed under the track by applying horizontal force after digging ins ide the box. Rest of the work in Railway premises to be done as a cast in situ box. The above work is to be done for M/S Reliance for transporting petroleum products required for new export refinery which is being developed at a rapid pace. Location of line The propped work falls on a goods line between Kanalus and Sikka of Ahamedabad Okha BG single line of Rajkot division of western Railway. OKHA SIKKA SITE RJT KNL S VG ADI Salient features of Box Box S ize : 3 segments of 2 X 7.50 X 2.20 m (Clear) Pushing Length : 22.50 met Cast in Situ Box Length : 40.00 met Total Length : 62.50 met Project Cost : 290.55 Lacks (in railway portion only) Grade of concrete : M35 concrete per RM : 28.275 Cum Dead weight of twin box : 1600 Mt.capacity Thickness of top and bottom slab of box : 750mm Thickness of wall was : 500 mm Cushion : 2m Bank height at Box location : 2.7 meter. Work was supervised by M/s Rites Box Dimensions: Rai lway Track Embankmen t 7.50m 2m 2.35m R.C.C Box Segment-I R.C.C Box Segment-II R.C.C Box Segment-III How site condition deteriorated On 1st July 2007 heavy rain took place from Rajkot to khambhaha in a stretch of 150 km. Major breaches took place at 04 (four) locations between Rajkot and Kanalus station of Rajkot division. The goods line from Kanalus to Sikka on which proposed work falls was isolated and goods loading/unloading was completely stopped. Advantage was taken to push all three box segments by cutting embalmment as it was expected that traffic will not be restored at least in next 7 days. So work was taken on a mass scale by M/s Reliance. Two segments of twin boxes i.e. 2 * 7.5 m*2.2 m has been successfully pushed through. Third segment was pushed through unto first edge of embankment. At this stage due to further heavy rainfall and failure of most of pushing jacks, work was to terminate at this stage. The earth in the form of crushed stone was filled and track was relayed. Mean time breaches at all four sites were attended and traffic restored to normal. rd Due to loose soil at the location of 3 segment; it was not possible to push box in normal way as there were 100% chances of falling loose soil during pushing. Efforts done to overcome problem Followings methods were tried to overcome difficulty of falling of overlaid loose soil • Stabilization of soil by Bentonite It was thought to use Bentonite to strengthen loose soil. The Bentonite was injected at closure spacing from top of embankments.By use of Bentonite, soil gets compressed and stabilized. M.S. plate in horizontal direction at centre of Front shield was provided to stop sliding of soil. Now digging started but unfortunately slope inside box started collapsing. Work was stopped again. The scheme was not successful due to presence of crushed stones in large proportion. M.S. Plate in Horizontal direction at centre of Front sheild to stop sliding of soil. Extra M.S. Plate R.C.C B ox • Complete block ing of line It was thought to block the line completely for 3 days being a goods line. But due to continuous loading and unloading of rakes, it was not economical as work was not so much urgent. However, there were spells of 3 to 4 days available but these spells could not be predicted. Agency desired for confirmation of block at least 7 days before start of block. Due to no confirmation given by Railway and also keeping in mind no urgency of work, this scheme was dropped. • Use of relieving girder The work could be done by use of relieving girder of 30m or more .As location falls in a rising gradient, a minimum 30 kmph speed was must for single loco. Speed lim it at relieving girder site was 10 kmph. Double loco system was not introduced due to scarcity of diesel locos. Due to these facts use of relieving girder was not suggested. • Supporting track transversely on two end beams A meeting was done with M/s Reliance and their contractor for finding out scheme. During meeting a scheme to support track transversely on two beams were discussed. A tentative scheme with design calculation submitted by agency which was cheched,modified and approved by CBE. The detail scheme was as under. 10m long ISMB 450*300 were to be inserted between sleepers. One end of this ISMB was to be supported on longitudinal RCC beam cast parallel to track at a distance of 6 m from centre line of track while other end was to be supported on top of vertical column made of CC crib on top slab of RCC box. A steel plate of 10 mm thick was to be placed on top of box and also below bottom of CC column. A lubricant was to be fed between these two plates so that a relative movement takes place between bottom plate fixed to RCC box and bottom plate fixed below CC cribs. Due to relative movements, crib to be remains at fixed location while box to be move ahead on jacking. Beside this, bottom plate under CC crib was also to be kept tight by rope and Pulley. The transverse beams were to be tied to each others by channel parallel to track at both side of track. Sketch of Supporting System: R.C.C Beam Casting: Execution methodology • • • • • • • Erect CC crib staging over the existing Pre cast Box to be pushed with 10mm M.S. plate on top of box & bottom of CC crib with lubrication in between. Cast 450 X 600 mm RCC beam on the other side of the track. Push ISMB 450 girder one by one in between the sleepers by removing ballast & excavation if required and fill the gap between sleepers with ballast. After completing the above supporting arrangements of track pushing of box will be done slowly at the rate of 250 mm at one stroke excavating max 300 mm earth from inside of box in one time. Filling of earth above box shall be done simultaneous ly. Pushing will be completed by repeating the above. The supporting arrangements of track are in addition to the normal safety arrangements for box pushing works. After box pushing the rail traffic will to be opened only after filling the earth back upto track & erecting the track fit for movement by Railway Engineer Incharge Execution Earthwork on opposite side of the box was done, rammed and rolled to the desired MDD and OMC for the purpose of resting CC beam. As per drawing CC beam of size 450 X 600 mm was cast on rolled earth at a distance of 6m from centre line of track having length 2 meter more than width of box. A plate 12 mm was fixed on top of slab. Lubricant was placed on this plate. On this plate, a CC cribs having bottom plate was fixed .The CC cribs were braced to each other .Top of CC crib and CC beam was kept 450mm below bottom of rail to facilitates insertion of ISMB. SR 30KMP H was introduced and one lookout man deputed on the track to ensure safety of track. ISMB 450 X 300 mm were inserted into the sleeper spacing one by one in all the spans in entire width of the box. One ends supported on CC cribs and another end supported on precast CC beam. Full packing of sleeper and ISMB ensured after insertion of ISMB. All ISMB braced with each other. Now we are in a position to take the complete load of the train on CC cribs rested on precast box on one side and on precast CC beam on other side through ISMB 450mm Approx 1000 of filled sand bags were kept ready to meet any unforeseen problems on work site. MS plates placed on box tightened with horizontal chain pulley to pull the plate simultaneously when box pushing started. Box was pushed up to 4 m distance from centre line of track before supporting arrangements prepared. A team of 20 labor of contractor kept ready to meet all the problems with the track and for packing and aligning the track and to meet with other problems. The total weight of twin box was 1600 MT so 12 number of jacks having capacity 150 Mt each were utilized for pushing the box i. e. 6 jacks on each box. Two numbers of bobcats were utilized to remove the earth from box and manual labors utilized to remove the earth in fronts of cutting edge. One crane was kept ready to meet any emergency. Box pushing started and simultaneously it was ensured that plates were tightened with the wire ropes and horizontal pulleys. Main purpose of this was to get relative movements between box and MS plates placed on it. Problem came during pushing work when formation of earth started to fall beyond last ISMB i.e. to near to edge of the box. Work was required to stop for sometime and two extra ISMB each end inserted into the spacing beyond the width of the box and collapsed earth was supported by placing filled sand bags. Pushing work was started slowly by removing earth from inside of box and then jacking. The pushing beyond other edge of sleeper could not be done due to falling of earth toward CC beam as distance of beam from edge of collapsed earth remains 02 m. Now it was decided to construct a CC wall on the edge of the box, approximate 0.5m width and up to the bottom of the rail. After construction of CC wall earth was filled between this CC wall and CC cribs on the box and slowly loads of the track transferred on newly filled formation earth retained by CC wall. After doing above work approximately 30 cm pushing done again and work of pushing was then stopped .Now precast cc beam was dummy and was require to remove as box was require to cast at that location cast in situ. ISMB inserted in the sleeper spacing removed one by one. Ballast putting and packing work done simultaneously. Further improve ments to scheme The ISMBs were laid in a width of box plus 2m only. When excavation was started collaps ing of earth from side of box also started along with collaps ing earth ahead of the box which was not thought off.However,the collapse was prevented by providing sand bags as well of CC cribs along sides of box .Also additional ISMBs were provided on both sides of box.So,additional requirements of ISMBs should be provided to cater side collapsing of earth. What was lubricant Availabilty of relieving girder Nos of rakes per day Material transported Inches of rainfall Role of lime grouting Bentonite from top or elsewhere