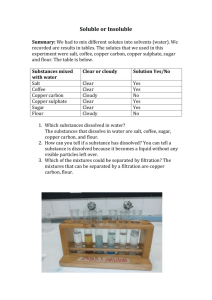

Survey of copper(I)oxide, copper(II)sulphate and

advertisement