Vortex Generator Flight Tests — Stall Effects

by David F. Rogers

http://www.nar-associates.com

Vortex generators (VGs) are usually associated with

multiengine, STOL or military aircraft. On multiengine aircraft, e.g., a Baron, the principal attraction is a significant improvement in single engine

handling qualites. Recently, a number of STCs have

become available for single engine aircraft including

one from Beryl D’Shannon (BDS) for the Bonanza.

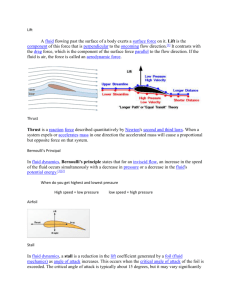

Vortex generators work by re-energizing the flow in

the boundary layer, that thin layer of air of reduced

airspeed right next to the surface. It is separation

of the boundary layer from the upper surface of the

wing that causes stall. Re-energizing the flow in the

boundary layer delays stall and increases the stall

angle of attack. The result is a higher wing lift coefficient and hence a lower stall velocity. Used in

front of or on control surfaces, e.g., ailerons, the

vertical tail/rudders or the horizontal tail, they increase control effectiveness at slower speeds.

The BDS kit consists of 39 VGs installed approximately 10% behind the leading edge of each

wing. Eleven VGs are installed on each wing ahead

of the inboard and outboad ends of the ailerons, and

12 VGs are installed on each side of the vertical tail

ahead of the rudder for a total of 124 VGs in two

different sizes (see Figure 1). The STC installation

Figure 1. Vortex generators.

instructions are very clear and detailed. Detailed

templates are provided to precisely locate the VGs

on both the wing and the vertical tail (shown in

Figure 2). Complete installation was accomplished

in approximately eight hours. The installed VGs are

shown in Figures 3 and 4. An optional 100 lb. gross

weight increase is available. However, the STC for

the gross weight increase changes the aircraft from

utility category (4.4 gs) to normal category (3.8 gs)

when operating at the increased gross weight.

Stall characteristics The straight tail and the

later V-tailed Bonanzas have two stall/spin strips

Figure 2. Vertical tail installation templates. VGs layed out

on the horizontal tail for installation on the vertical tail.

Figure 4. Vortex generators installed on wing.

Figure 3. Vortex generators installed on vertical tail.

mounted on the inboard section of the wing (see Figure 5). The inboard stall/spin strip (black arrow),

mounted at the crank of the wing, activates at a

higher angle of attack than the outboard six inch

long stall/spin strip that looks like a small piece of

angle iron (white arrow).

As the aircraft is pitched up the airflow comes

from underneath the outboard stall/spin strip. If

the airflow comes from underneath the sharp edge

of the stall/spin strip, the local airflow immediately

behind the stall/spin strip separates from the wing

and flows aft in a narrow turbulent stream. Because, as shown in Figure 5, the elevator balance

horn is located immediately behind the small outboard stall/spin strip, the narrow stream of separated turbulent air impinges on the horn and shakes

the elevator and hence the control yoke — in effect

it acts as an aerodynamic stick shaker.

As the aircraft continues to pitch up at a moderate rate, the inboard stall/spin strip located at

the crank of the wing activates. Here a stronger locally separated turbulent flow is generated which,

as Figure 5 indicates, impinges on the center of the

elevator and literally shakes the entire aircraft with

a significant up and down pitching motion. If the

aircraft continues to pitch up at a moderate rate,

a full stall occurs. Hence, with moderate or faster

pitch-up rates there are two significant warnings of

an impending stall. This constitutes good design.

Flight tests without VGs The no VG flight

tests were conducted by a single pilot at pressure

altitudes from 4000 to 8000 feet. Takeoff weight was

2861 lbs. The weight during the flight tests varied

Figure 5. Stall/spin strips.

from 2839 to 2746 lbs. The center of gravity was

80 inches aft of the datum. Tests were conducted

at bank angles from zero to thirty degrees both to

the left and to the right. Power off tests were conducted at idle power in descending glides. Power

on tests were conducted both at full throttle and

2700 RPM and in the power approach configuration (2300 RPM and approximately 23 inches of

manifold pressure or full throttle). All tests were

conducted using a slow approach to stall, i.e., a deceleration of one knot per second or less as specified

in FAR 23.201. Fuel burn was from the left tank.

In the power off clean configuration (gear and

flaps retracted), flight test results show that for

zero bank angle the aircraft stalls at 61+1/−0 miles

per hour indicated airspeed (MIAS). Noting that

the POH shows negligible airspeed correction at 60

mph, at the test weight the POH gives a stall speed

of 66.7 MIAS at 2800 lbs. The most likely explanation for the difference in stall speeds is the FAR

requirement that the value in the POH be for the

worst case (FAR 23.49), which is typically for the

center of gravity at the forward limit of 77 inches.

In both right and left 20◦ banks, stall occurred

at 64 MIAS, while in right and left 30◦ banks stall

occurred at 69±1 MIAS. In all cases a mild wing

drop (typically to the right) occurred or the aircraft

gently bobbled up and down while descending. In

all cases, solid aileron control was maintained up to

and into the stall. This is not surprising, in view of

the fact that both experimental tuft and analytical

studies show that on the Bonanza wing stall begins

at the trailing edge 1–2 feet outboard of the root

and smoothly progresses forward and outward on

the wing. The flow on the wing in the region of the

ailerons does not begin to separate until the stall

is nearly fully developed on the inboard portions of

the wing. Stall recovery was initiated by returning

the control column to a neutral position. Power was

not added.

In the power off dirty configuration (gear and

flaps extended) flight test results show that for zero

bank angle the aircraft stalls at 53+0/−1 MIAS. In

20◦ left and right banks stall occurs at 55+0/−1

MIAS, while in a 30◦ left bank stall occurred at

59 MIAS. At stall a mild left wing drop or gentle

bobble occurred. Aileron control was good.

At full power at 7500 feet pressure altitude (22

inches MP and 2700 RPM) in the clean configuration with zero bank angle, stall occurred at an

average of 55 MIAS while climbing in excess of 500

fpm. Full right rudder was required. In the power

approach configuration (full throttle – 21.5 inches

MP and 2300 RPM) at 7800 feet, gear and flaps

extended with zero bank angle, stall occurred at 54

MIAS. Full right rudder as well as some right aileron

was required to overcome a left turning tendency.

Good control was maintained. Prior to the stall the

aircraft continued to climb. Upon stall the aircraft

rolled to the right. In 20◦ left and right banks the

aircraft also stalled at 54 MIAS. Again, full right

rudder as well as some right aileron was required to

overcome a left turning tendency. Good control was

maintained. Prior to the stall the aircraft continued

to climb. Upon stall a mild left wing drop occurred.

Flight tests with VGs The flight tests with

the VGs installed were conducted under the same

conditions as those without VGs installed. In the

power off clean configuration for zero bank angle

the aircraft stalled at 53 ± 1 MIAS with the VGs

installed, which represents a reduction of 8 MIAS

compared to without VGs. The stall was not as well

behaved as without the VGs installed. The resulting

wing drop was more aggressive. The stall warnings

generated by the stall/spin strips were significantly

decreased. The most likely explanation for the decreased stall warning is that the VGs cause the separated flow from the stall/spin strips to reattach to

the wing until significantly higher angles of attack.

At these higher angles of attack the wing stalls more

abruptly with the VGs installed.

In the power off dirty configuration with VGs installed the aircraft stalled at 50±1 MIAS, which represents a reduction of 3 MIAS compared to without

VGs installed. In this configuration stall occured

with the column full aft. Using 25◦ of trim, i.e., all

available trim, was insufficient to reduce the stick

force to zero. With the ball centered, the aircraft

bobbled upon stalling. This observation, along with

the small difference in stall speed with the VGs installed and the full aft column, suggests that, using

the slow stall technique, a fully developed stall may

not have occurred because of lack of elevator power.

Vortex generators on the underside of the horizontal

stabilizer ahead of the elevators to increase elevator

power may be indicated. Aileron control was solid.

At full power (22 inches MP, 2700 RPM, OAT

of 45◦ F at 7600 feet pressure altitude) in the clean

configuration with zero bank angle, stall occurred

at 52 ± 1 MIAS while the aircraft was climbing.

Full right rudder and partial right aileron was insufficient to prevent a left turning tendency. In the

dirty configuration with zero bank angle stall occurred at 47 ± 1 MIAS. Full right rudder with partial right aileron was necessary. Aileron control was

solid. During stall, significant wing drop of as much

as 45◦ occurred.

In the power approach configuration (23 inches

MP and 2300 RPM) gear and flaps extended with

an OAT of 50◦ F at 7500 feet pressure altitude with

zero bank angle the aircraft stalled at 50 + 1/−2

MIAS while climbing. With the same power settings in the clean configuration stall occurred at

53 + 1/−2 MIAS. Again, right rudder and aileron

were required to prevent a significant left turning

tendency both clean and with gear and flaps extended. In the dirty configuration left and right

banks between 10◦ and 30◦ resulted in a stall velocity of 51 ± 1 MIAS independent of bank angle.

Wing drops of up to 45◦ were experienced. Both in

the full power and the power approach configurations the deck angle was estimated as 25 − 30◦ .

Summary The Bonanza, as originally equipped,

has excellent low speed handling and stall characteristics with good multiple stall warnings provided

by two stall/spin strips. As a result, the aircraft has

good short field characteristics.

At the test conditions, the VGs reduced the

power-off stall speed in the clean and dirty configurations by 13% and 6% respectively. In the dirty

power approach configuration a 7% decrease was

found. For all test cases good aileron and rudder

control were maintained. Previously, without the

VGs install, I was quite happy to come down short

final at 85-90 MIAS for a short field landing. With

the VGs, 75-80 MIAS is quite comfortable although

I generally use 82 MIAS because the stall warning

horn activates at 80 MIAS. These results make a

good short field aircraft even better.

As with anything, the reduction in stall speed

comes with a price. Specifically, VGs adversely affect flying qualities near stall, especially aerodynamic stall warning. Furthermore, the actual stall

is more aggressive as indicated by significant wing

drop. However, if you need to get in and out of

short fields or just want that extra margin above

stall, the cost may be acceptable.

Because of recent flight restrictions, characteristics at the optional 100 pound gross weight increase

were not tested. A separate article will discuss the

effect of vortex generators on cruise speed.

c

Copyright 2002

David F. Rogers. All rights reserved.