Quality Management

advertisement

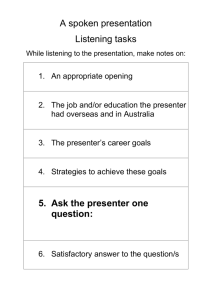

CPM -100: Principles of Project Management Lesson C: Quality Management Presented by John Cormier PMP cormierj@erols.com Ph: 703-819-7776 Presented at the IPM 2003 Fall Conference Prepared by the Washington, D.C. Chapter of PMI Presenter: John Cormier PMP Quality • Quality is: – Conformance to requirements – Fitness for use. • Quality is not: – Luxury, – Gold plating, – High grade or prestige. Presenter: John Cormier PMP COMPATIBILITY • The PMI approach to quality is intended to be compatible with the International Organization for Standardization (ISO). • The PMI approach is also compatible with proprietary approaches to quality such as those recommended by gurus such as Deming, Juran, and Crosby Presenter: John Cormier PMP Guru Legacies • Deming: Plan-Do-Check-Act (PDCA) and the Japanese “Deming Award”. • Crosby: “Quality is Free” & Zero Defects. • Juran: “The Quality Trilogy” of Planning, Control and Improvements. • Feigenbaum: “The Cost of NonConformance” Presenter: John Cormier PMP Project Process Groups Planning (Quality Plan) Initiating Controlling (QC) Executing (QA) Closing Presenter: John Cormier PMP Quality Planning INPUTS 1. Quality policy 2. Scope statement 3. Product descriptions 4. Quality standards and regulations. 5. Other: procurement planning, contract stipulations, risk planning, etc TOOLS & TECHNIQUES 1. Benefit/cost analysis* 2. Benchmarking* 3. Flow charting 4. Design of experiments 5. Cost of Quality OUTPUTS 1. Quality Management Plan. 2. Operational definitions 3. Checklists and inputs to other processes Presenter: John Cormier PMP Planning For Quality • Benefit/cost analysis: Finding ways eliminate rework, lower final costs, and increased stakeholder satisfaction. Finding trade-offs. • Benchmarking: Looking for “best practices” that can improve quality and performance. Presenter: John Cormier PMP Planning For Quality • How do you determine the tolerance for defects? – Corporate policy – Contract requirement – User expectations • How much quality is “good enough”? • How do you measure quality? – New 6 sigma? – Traditional 3 sigma? Presenter: John Cormier PMP 3 Sigma (σ) Bell Curve Presenter: John Cormier PMP Traditional Industry Standard • Three sigma (σ) equals three standard deviations above and below the mean. • This represented 99.73 of the area under the normal distribution curve that represented the total population of products produced. • Three sigma quality means 99.73% of products are defect free. • Sounds pretty good, wouldn’t you say? Presenter: John Cormier PMP Three Sigma Calculations (1994) • 20,000 incorrect prescriptions per year. • 70 incorrect surgical operations per day. • 16,000 pieces of mail lost each hour. • 10 commercial airline crashes per day. • 22,000 checks deducted from the wrong bank account each hour. • 15 minutes without electrical power daily. Still happy with three sigma? Presenter: John Cormier PMP How Much Quality is Enough? • Today, the traditional 3 sigma capability is not good enough for many industries and customers. • New goal is 6 sigma! Variances will be so small that there will only be 2 defects outside the control limits for every billion units produced. • Can you ever reach zero defects? Presenter: John Cormier PMP Planning For Quality • Flowcharting: Using diagrams to show relationships i.e., cause/effect diagrams, process flow diagrams, etc. • Design of Experiments: Identifying variables that can influence outcomes and evaluating options that offer cost advantages without impact to quality. Presenter: John Cormier PMP Process Flow Diagram System Requirement Delivery and Installation Customer Acceptance Preliminary Design Validation Testing Final Design Fabricate and Assembly Where would you have check points? Presenter: John Cormier PMP Cause & Effect Diagram Example (Fish Bone or Ishikawa Flow Chart) Cause Time Machine Method Effect Material Major Defect Energy Measure People Environ. Quality Control Tool & Technique • Brainstorm probable causes for the defect. • Classify in related groups. • Start solving with the group having the most likely cause. Presenter: John Cormier PMP Assessing The Cost of Quality • Cost of Conformance: – Prevention costs – Appraisal costs. • Cost of Non-Conformance: – Internal failure costs. – External failure costs (includes loss of customer confidence). Presenter: John Cormier PMP Outputs of Quality Planning • Quality requirements defined • Operational definitions (metrics for quality assessments). • Checklists for QA and QC. • The Quality Management Plan Presenter: John Cormier PMP Quality Assurance TOOLS & TECHNIQUES INPUTS 1. Quality Management Plan 2. Results of Quality Control measurements 3. Operational definitions. 1. Quality planning tools such as Benefit/cost analysis, benchmarking, flow charting, cause effect diagrams, etc 2. Quality Audits. 3. Promote quality at the source OUTPUTS 1. Quality improvements to include new initiatives, corrective actions and Presenter: John Cormier changes PMP Assuring Quality • Application of quality planning tools and techniques such as: – Benefit/cost analysis – Benchmarking – Flow charting – Cause effect diagrams • Auditing • Promoting quality at the source. Presenter: John Cormier PMP Managing Quality Control TOOLS & TECHNIQUES INPUTS 1. Quality Management Plan 2. Results of work 3. Checklists 4. Operational definitions 1. Inspection 2. Control charts* 3. Pareto charts* 4. Statistical sampling 5. Flow charting 6. Trend analysis OUTPUTS 1. Risk Management Plan. Presenter: John Cormier PMP Quality Definitions • Attribute: A characteristic that reflects. conformance or non-conformance to specifications and tolerances. A go-nogo metric. • Variable: a characteristic that can be measured in increments related to control limits. • Probability: The percentage of chance that something will happen. Presenter: John Cormier PMP Quality Control Definitions • “Rule of Seven”: When seven consecutive samples are found on one side of a control chart specification, the process is statistically out of control. • Process Control Assessment: Testing a process to determine if control limits are within customer acceptance tolerances. Presenter: John Cormier PMP Sample Control Chart UCL o USL o o o Specification o o o o X o o o oo o LSL LCL UCL = Upper Control Limit USL = Upper Specification Limit LCL = Lower Control Limit LSL = Lower Specification Limit Presenter: John Cormier PMP o o Statistical Sampling • Tolerances – Upper and Lower Control Limits. – Upper and Lower Specification Limits. • Out-of-Control Situation – A data point exceeds a limit. – Rule of Seven occurs. Presenter: John Cormier PMP Control Chart Variances – Random Variance: Variations normal to the process and deemed acceptable. – Special Variance: Variations outside the normal range that can be assigned a cause (special or assignable cause) and the process needs to be fixed. Presenter: John Cormier PMP Pareto Diagram • A histogram of defects, ordered by the frequency of occurrence. • Rank ordering is used to focus corrective action on the most often occurring problems. • “The 80/20 Rule”. The majority of defects (80%) are usually caused by a vital few (20%) of the problems. Presenter: John Cormier PMP Pareto Chart Presenter: John Cormier PMP Statistical Sampling • Attribute Sampling: Determining whether to reject or accept the entire lot (go-no go decisions). • Variable Sampling: Using control charts to measure variance in a process to determine the process capability and deciding whether to accept or reject. Presenter: John Cormier PMP Output of Quality Control • Quality improvements • Acceptance decisions • Rework decisions and scrap • Rejection of deliveries • Documentation • Process adjustments Presenter: John Cormier PMP Quality Team Responsibilities • Customers - Set the requirement. • Senior Management - Sets the tone. • Project Manager - Select & implement quality requirements. • Quality Staff - Monitor & inspect for compliance. • Suppliers / Vendors - Meet the specified quality standards. • Project Team - provide quality at the source. Presenter: John Cormier PMP