automotive service technician 1

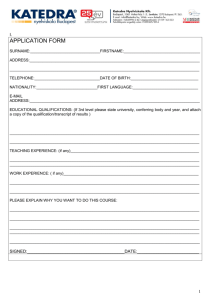

advertisement