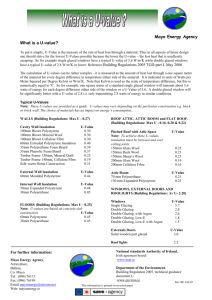

Approved Document L1 (2002)

advertisement