CLASS ASSESSMENT APPROACH ON THE AROMATIC AZO

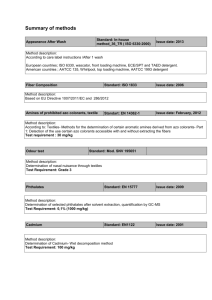

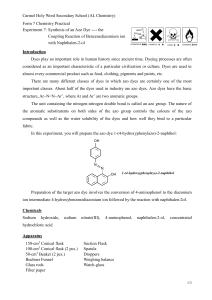

advertisement