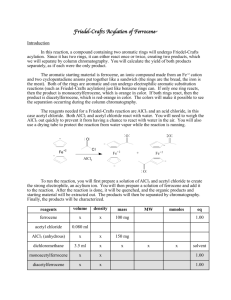

Friedel-Crafts Acylation of Ferrocene Lab Experiment

advertisement

Revised Experiment #14 Revised Experiment #14 Friedel-Crafts Acylation of Ferrocene: Acetylferrocene Required Reading Review Column Chromatography and Thin-Layer Chromatography Discussion The Friedel-Crafts acylation of benzene derivatives (Exp. 17) requires aluminum chloride, a strong Lewis acid, as a catalyst. In contrast, Ferrocene, a “superaromatic” compound, will readily react under milder conditions, with acetic anhydride and phosphoric acid as the catalyst. Since acylation reactions put a deactivating group on an aromatic ring, and the risk of getting di- or poly-acylated products should be minimal, but some diacetylferrocene might be formed. In this synthesis you will isolate and purify unreacted Ferrocene, acetylferrocene as well as any poly-acylated products. Each additional acetyl group changes the UV-VIS absorption of the compound (through increased conjugation) and therefore each compound is a different color and easily identifiable. O O Fe H3PO 4 + O Ferrocene Bis(cyclopentadienyl)iron MW 186.04, mp 174 °C Acetic Anhydride CH 3 CH 3 C Fe O C + H 3C Fe O C O Acetylferrocene (Acetylcyclopentadienyl)cyclopentadienyliron MW 228.08, mp 85 - 86 °C 1,1'-Diacetylferrocene Bis(acetylcyclopentadienyl)iron MW 270.1, mp 125 - 127 °C 71 Revised Experiment #14 Special Instructions Acetic anhydride and phosphoric acid are corrosive - avoid breathing these compounds and wear gloves to avoid contact with your skin. Prelab Remember that the table of chemicals should list all chemicals which will be encountered in this experiment. This includes all products (well, the mono- and di- acetylated products) as well as all reactants, solvents, and chemicals used in the work-up and purification of the product(s). The Prelab should also give balanced equations for all reactions and calculate a theoretical yield for acetylferrocene. Procedure for the Synthesis Pre-heat a sand bath to 100 °C. Meanwhile, set up a reflux apparatus that consists of a 3- or 5- mL conical vial, a water condenser, and a drying tube. Connect the tubing for water to circulate through the condenser. Do not use CaCl2 or cotton in the drying tube. Instead, place a small amount of glass wool in the drying tube and then add a few drops of water to the glass wool to moisten it. Keep the entire assembly well above the sand bath until all of the reagents have been added to the vial. Remove the conical vial from the apparatus, add 93 mg of dry ferrocene and cap the vial. Take the capped vial to the hood and, using two automated pipets, add 0.35 mL of acetic anhydride and 0.1 mL of 85 % phosphoric acid (H3PO4). Cap the vial again for transporting it back to your bench. Reattach your conical vial to the apparatus and begin stirring. When the sand bath has reached 100 °C, start the water circulating through the condenser and lower the apparatus onto the sand. Heat the mixture for 15 minutes – the reaction mixture does not need to reflux. After the 15 minutes, remove the apparatus from the sand bath and allow to cool to room temperature. Remove the water condenser and cap the vial. Cool the vial in ice water until cool to the touch. In a hood, carefully add 0.5 mL of ice water dropwise, while thoroughly stirring the mixture with your small stir rod. Again, dropwise, carefully, and in the hood, add 10% NaOH until the acids are neutralized (how can you tell?). Avoid adding excess base, as this can decompose your product(s). Collect the products on a Hirsch funnel, washing them thoroughly with water (cold water? warm water?). Dry the product on the vacuum followed by pressing the product between two pieces of filter paper. Save a small amount of the crude product for later TLC analysis. 72 Revised Experiment #14 Column Chromatography Obtain a column (1-cm in diameter and 15-20 cm long) from the side counter. Set up the column as you did for Exp. 7 (Column Chromatography), although you do not need to put a “plug” of sand at the top of the column. Be sure to leave room to load your product and eluent on top of the alumina – it is best if the alumina takes up roughly 2/3 of the column (about 3.5 g alumina), leaving the final third for your product and eluent. Use hexanes as your eluent. Dissolve the crude product in a few drops of methylene chloride and apply the solution/suspension to the column without disturbing the top of the alumina. Open the stopcock and allow the sample to penetrate the alumina. Close the stopcock again when the solution is just at the top surface of the alumina. Complete the transfer of the crude product by adding a few more drops of methylene chloride to the original vial/tube and applying this solution to the column and allowing it to enter the top of the alumina, as before. Once all of the sample is in the alumina, pour a small amount of sand onto the top of the column to protect the surface of the alumina while the eluting solvents are being added. Add hexanes to the column, being careful not to disturb the alumina, open the stopcock, and start eluting the product from the column. First a yellow-orange band of unreacted ferrocene will come down the column if some of your ferrocene did not react. Collect this in a tared 10 mL flask, and, with a Pasteur pipet, also use hexanes to rinse off any crystals which may form on the tip of the stopcock. Then elute the column with a pre-prepared 50:50 mixture of hexanes and methyl t-butyl ether. This solution will bring down the acetylferrocene (an orange-red band). Collect the product in a tared 10 mL flask, and once again rinse off any crystals which may have formed on the tip of the stopcock. Finally, if you have a dark band at the top of your column (diacetylferrocene), elute it using acetone as the eluting solvent. Collect it in the same fashion as you have collected the other samples. Before proceeding further, spot a silica gel thin-layer plate with all three solutions obtained from the chromatography. Allow space for six to eight total spots on the plate: the other spots will be defined later. You will need eight spots if you obtained any diacetylferrocene from the reaction. Keep this plate for analysis as described below. Evaporate the solvents from the three flasks and determine the weights of the residues. Recrystallization Recrystallize the acetylferrocene in a Craig tube using hexanes. Once the product is dry, determine the weight and calculate a percent yield. In addition, determine a melting point, and analyze it by thin layer chromatography. Consult your instructor to determine whether to turn in your product or not. If you are turning in your product, do not forget to properly label the vial! 73 Revised Experiment #14 Thin Layer Chromatography To the thin layer chromatographic plate prepared above also apply the following substances: starting material (ferrocene), crude product which had been saved for this purpose, recrystallized acetylferrocene, and pure acetylferrocene and diacetylferrocene provided for analysis. Use toluene to dissolve the solids for application to the plate (each sample will just require a tiny amount of solid and a few drops of solvent). Develop the chromatogram with a 30:1 mixture of toluene and absolute ethanol. Most of the spots should be visible, but to be sure nothing is missed, examine the plate under a UV light. Report all spots observed and try to identify each one. Questions 1. Draw structures for other possible diacetylferrocene compounds and explain why the structure given in the introduction is the most likely by-product of this synthesis. 2. Propose a mechanism for the acylation of ferrocene. 3. Why does the acetylferrocene not move much on the column while the column is being eluted with hexanes? Acknowledgement: This experiment has been modified from Macroscale and Microscale Organic Experiments by Kenneth L. Williamson, D.C. Heath and Company, 1989. 74