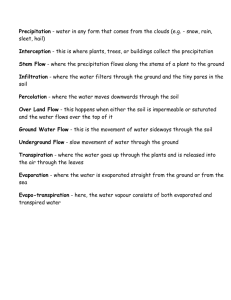

Chapter 71 Soil Water Potential

advertisement