Leveraging Vacuum-coated PET Films

for Highly Energy-efficient Windows

Chris Stoessel

Contributed Original Article

Southwall Technologies Inc., Palo Alto, CA

T

he introduction of low-emissivity coatings has been a quintessential contribution to improve the energy efficiency of modern

windows. Dramatic improvements in low-e coatings (especially

through silver-based “soft” sputter coatings) and stack designs have

yielded a vast range of solutions for various climatic, aesthetic and

comfort requirements. However, to achieve maximum thermal insulation especially for cold-climate regions in modern concepts such as

Passive Houses (where the solar irradiation contributes to the heating

of the building), low-e coatings alone do not provide the best results –

they typically need to be combined with insulating gas cavities to form

insulating glazing units (IGUs). With the emissivity and spectral performance of coatings almost at their theoretical optimal levels, improvements of insulation performance to meet modern energy efficiency

standards can be improved primarily by adding additional gas cavities,

which increases the weight and thickness of windows due to the additional glass panes. Replacing the internal glass panes with suspended

thin, low-e coated polymer films can effectively address these challenges, and has proven to be a robust solution for highly insulating IGUs

for residential and commercial architectural windows. The design and

production of the low-e coatings must be adjusted to the constraints of

the polymer substrate and integration aspects into the IGU to ensure

optimal performance at a cost that supports broad market adoption.

Introduction – contribution of architectural windows to

energy efficiency

According to government studies, about 49% of the entire energy consumption in the US is spent on heating and cooling buildings. Of this

amount, approximately 30% [1] or 12% of total energy consumption is

attributed to windows, representing an annual impact of 4.1 Quads [2].

Highly insulating windows with U-factors as low as 0.09 BTU/hr-ft2-F

can deliver a potential annual U.S. residential energy savings of 1 Quad/

year over the business-as-usual sales case [2] which would translate to a

CO2 emission reduction of 67 million tons/year [3]. This savings level is

largely limited to the residential market in the heating-dominated colder

climate zones and is best achieved with “Passive House” technologies

that combine high thermal insulation performance and controlled air

infiltration with the capability to maximize the contribution of solar

radiation to heat the house.

“Passive House” window design – combining insulation

with solar heat gain

Passive house window design can be characterized by two fundamental functions: (a) the capability to retain or reflect long-wavelength

radiation inside the house (at the wavelength of approximately 10

micrometer for a blackbody at 24°C room temperature), and to (b)

admit a maximum of solar irradiation (in the wavelength range of 0.3

to 2.3 micrometer). This performance represents a bandpass filter with

a ­transition from high transmission in the visible/near-infrared (IR)

region to a high reflection in the mid-/far-IR region. Thermal insulation performance of a window is described through the “thermal conductivity” (U-factor) or its inverse value “thermal resistivity” (R-value).

The capability to admit solar energy is described as “Solar Heat Gain

Coefficient” (SHGC), which is the fraction of incident solar radiation

admitted through a window, both directly transmitted and absorbed

and subsequently released inward.

While no formal performance value have been defined for a “passive house” window, a recent research program by the U.S. Department

of Energy [1] sets a goal of uwindow=0.1 BTU/hr-ft2-F (R-10) and

SHGC=0.5 for emerging windows geared to perform at the highest level

within this segment of the market.

The resulting window design is a combination of insulating cavities

and low-e coatings. Ideally, the cavities should be vacuum, however

such windows have never gained broad market traction due to technical, aesthetic and reliability constraints; the common solution is to fill

the cavities with a low-conductivity noble gas.

Modeling of thermal performance of windows

Thermal modeling of windows was performed in a separate study [4]

with WINDOW [5] software, utilizing IGDB [6] data (note: the l­atest

software version is WINDOW 7, and the current IGDB version is

29.0.0). The software allows analysis of standardized sizes and designs

of residential windows, calculating U-factor, SHGC and several other

performance values. For that study, two window types commonly

found in the North American market were analyzed: “vertical slider”

and “picture”.

The model calculates the thermal and optical performance analysis

of the key window components “frame”, “edge-of-glass” (EOG, typically

a 2-inch perimeter adjacent to the frame) and “center of glass” (COG),

all of the remaining glass in the window system, and the primary component influenced by thin film coatings. Within WINDOW, several

default options are available for frames and EOG, with modeling details

available in [4]. COG was modeled from a wide range of commercially

available glass and low-e coated film types that can be configured as

multi-cavity designs with specified cavity count, spacing distance and

gas fill within the unit’s cavities.

Modeling Results

The conductance of a window is calculated as the sum of the area

­contributions of the three components frame, Edge and COG:

U

Window

= (A

*U

Frame

Frame

+A

*U

Edge

Edge

+A

*U

COG

COG

)/A

Window

The area contributions from the two window designs examined in

[4] vary considerably, and the resulting U-factors highlight the importance of increasing the window aperture and minimizing edge and

frame contributions for effective Passive House designs.

COG contributes the lowest conductivity and the largest area, and

thus has the biggest leverage on window performance. It is notable that

even through the areas for frame and edge are less than a third of the

area for COG, they strongly dominate the thermal losses of the window,

particularly in the vertical slider which has a larger area contribution of

frame and edge in comparison to the picture window. Also, edge and

frame typically have higher conductivities compared to COG, consequently the adoption of “warm edge” solutions is an important trend in

the glazing industry. From a window design perspective, the significant

50 | SVC Bulletin Summer 2013

2013SummerBulletin1.indd 50

7/9/13 12:22 PM

Fig. 5: Insulation Performance of several IGU designs vs. Pocket Width

thermal losses incurred from the window frames call for minimizing

their cross-section in a window, which can be achieved by reducing the

structural load on the frames through light-weight IGUs with optimized

overall thickness.

COG performance is determined by the design of the IGU. Design

variables are the thickness and type of glass, type and location of low-e

coatings, number of cavities (in multi-pane IGUs), the overall thickness

(OAT, or “Pocket Width” in the frame) which determines the width of

the cavity, and the gas filling within the cavities.

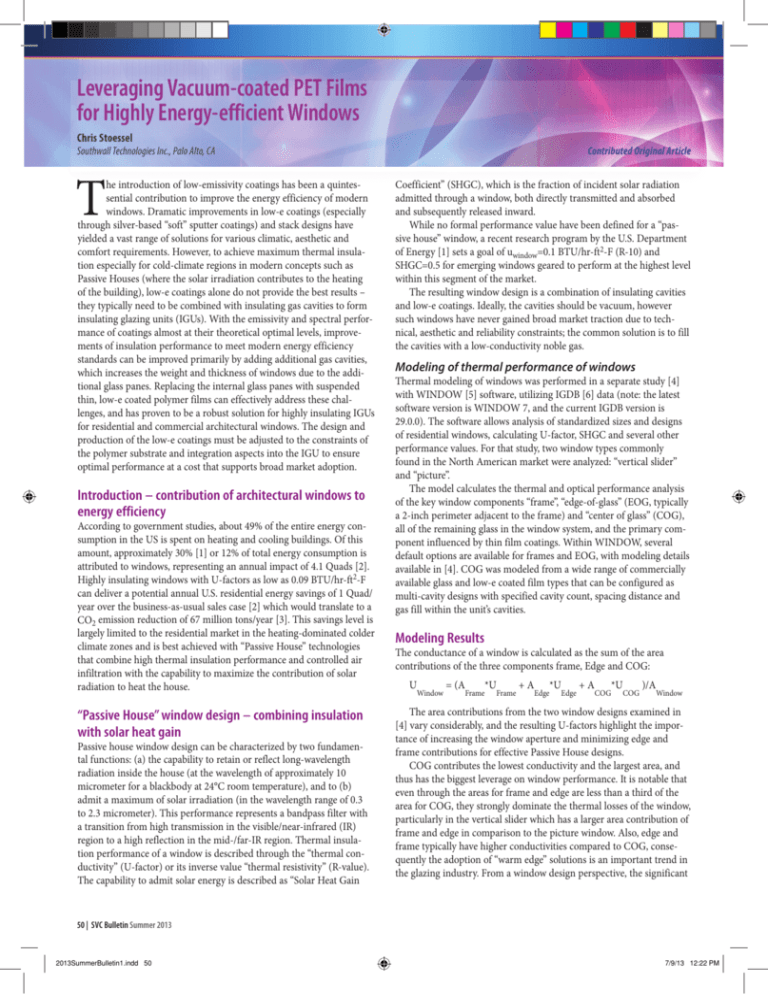

Figure 1 summarizes the effect of various design variations on the

thermal performance (U-factor) and SHGC of an IGU. For reference, a

single-pane window typically has a UCOG=0.93 BTU/hr-ft2-F. Filling a

non-low-e dual-pane (single-cavity) IGU with Krypton gas achieves a

UCOG=0.445 BTU/hr-ft2-F. Krypton filling an IG represents the highest

“commercially viable” performance for a single cavity IGU without a

low-e coating. Krypton is the best-performing fill gas commonly used

in the glazing industry, but its cost is a factor of approximately 500

times higher than that of argon, and thus can not be considered for

large-scale low-cost glazing solutions. Therefore, Argon-filled IGUs are

the de-facto standard for high-performance mass-market IGUs.

Adding a low-e coating (in this case and as an example, a modern

sputtered high-SHGC-capable single-silver “LoE-180™” softcoat produced by Cardinal Glass Industries, and denoted as “180” in the figures)

to the single-cavity IGU (filled with industry-typical argon/air mixture

of 90/10 vol%) improves the UCOG to approx 0.26 BTU/hr-ft2-F. Note

that there is an optimum cavity width (in this case for an OAT of 0.69”)

that is largely determined by the conductive thermal and fluid properties of the fill gas.

1-Cav (CLR-CLR) Air

1-Cav (CLR-CLR) Ar/Air90/10

1-Cav (CLR-CLR) Kr

1-Cav (180-CLR)

2-Cav (180-180-CLR)

2-Cav Heat Mirror (180-88-CLR)

3-Cav Heat Mirror (180-88-88-CLR)

4-Cav Heat Mirror (180-88-88-88-CLR)

3-Cav (366-CLR-CLR-CLR)

0.50

0.45

2

UCOG [BTU/hr-ft -F]

Center of Glass (COG)

0.55

0.40

0.35

0.30

0.25

0.20

0.15

0.10

0.05

0.63

0.75

0.88

1.00

1.13

1.25

1.38

1.50

1.63

1.75

1.88

2.00

2.13

OAT (inch)

Figure 1: Insulation Performance of several IGU designs vs. Pocket Width

A further improvement towards an R-10 window of conventional

design (low-e coated glass with argon fill) can be achieved through

adding one or two cavities and widening the IGU to accommodate sufficient cavity width. Dual-cavity design achieves an optimum of approx

UCOG=0.13 BTU/hr-ft2-F. Two variations are shown, one is an all-glass

(triple pane) construction with a low-e coating per cavity, the other

is a variation with a suspended low-e-coated polyester terephthalate

(PET) polymer film (in this case and as an example, Heat Mirror 88

produced by Southwall Technologies, denoted as “88” in the figures),

which reduces IGU weight and OAT by replacing the center glass. The

glass-based solution shows an advantage in the U-factor/SHGC balance,

indicating the optimized silver quality that can be achieved on glass

continued on page 52

Summer 2013 SVC Bulletin | 51

2013SummerBulletin1.indd 51

7/9/13 12:22 PM

Leveraging vacuum-coated PET films

continued from page 51

substrates as compared to polymer substrates. Performance exceeding

UCOG=0.1 BTU/hr-ft2-F can only be achieved with three or more cavities and an OAT of greater than 1.75”. Such windows (and especially

patio doors) are very challenging to build, install and use with all-glass

construction due to the significant weight increase of the additional

glass, whereas separating the cavities with low-e coated polymer films

effectively eliminates any increase in weight and allows for narrower

overall OAT. Improvements from adding additional cavities (beyond 3)

are modest especially for OAT dimensions less than 2”, mostly because

the cavities can not be made sufficiently wide to optimize the fill gas’s

thermal transfer characteristics. Adding more cavities will also reduce

the SHGC (due to the transmission losses of added glass/film and coatings), which is already below 0.5 for a 3-cavity IGU with low-e coatings

in each cavity. Hence, three cavities, with four glazing layers, represents

a potential “sweet spot”, with significantly improved thermal performance, while maintaining acceptable levels of solar gain (SHGC).

The selection of low-e coatings from the broad range of available

options is important to maximize the performance of a “passive house”

window. Figure 1 includes a comparison of replacing three low-E singlesilver coatings of a three-cavity unit with a single “LoE366 ” (triplesilver low-E glass produced by Cardinal Glass, denoted as “366” in the

figure) on the outermost (cold) glass. Such a design might be desirable,

as it reduces the amount of sensitive low-e-coated glass required to

build a multi-cavity IGU. Although the two configurations contain

­approximately the same amount of silver for the low-e functionality, the

single-coating option is significantly less effective, and also reduces the

SHGC significantly, and thus is not a successful approach for a passivehouse window.

The take-away from Figure 1 is a design concept for Passive House

windows that must effectively incorporate multiple cavities combined

with a high-efficiency (soft-coat) sputtered single-silver low-e coatings

in each cavity. The width of the cavities can be improved through the

use of thin polymer films especially if the overall thickness of the IGU

is constrained. The incorporation of suspended polymer films also

­supports a lower overall IGU weight.

have yielded soft-coat low-e coatings on PET with emissivity below 0.1

that can be exposed to the environment (in this case the inside of the

window) in the form of applied window films [11].

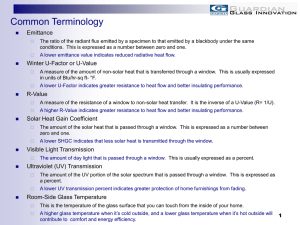

Aesthetics: Reflected Color

Architects and homeowners are often concerned about the appearance

of glass, primarily their reflected color. Here, the reflected color appearance is not only a result of the outermost surface but a composite of the

reflections and transmitted optics throughout the entire IGU package.

Undesirable variations in color are often caused by replacing windows

with different low-e coatings, or variations in IGU design (cavity count,

shading) within the same façade. Figure 2 shows the shift of reflected

color (at normal incidence) in the Ra*/Rb* coordinate space (of the

La*b* color system), starting from the slight green color of standard

float glass. Additional low-e coatings and cavities move the reflected

color further towards blue (and green in the case of all-loE180-coated

glass). While not shown here (and difficult to model without detailed

knowledge of the low-e coating stacks), color variations can be even

more pronounced

angles.

Fig.at

6: non-normal

Reflected Colorviewing

for various

glazing designs

-3

TM

High-efficiency soft-coat low-e coatings

COG performance is highly dependent on the quality of the low-e

coating. Most modern high-performance low-e coatings for glazing

applications rely on silver as the infrared-reflecting filter element, and

the quality of the silver film is characterized by achieving low emissivity

at the highest possible visible or solar transmission. The best-performing silver films are sputter-coated on smooth substrates to suppress

absorption-inducing plasmon resonance interference effects [8]. Also,

it has been shown that special seed layers that achieve a homogeneous

and fine grain structure improve the performance of low-e coatings [9].

From a web coater equipment and process control perspective, the bestperforming silver films are deposited in process conditions that inhibit

detrimental silver oxidation [10] by ensuring good gas separation from

adjacent reactive sputter processes that deposit the dielectric layers.

When applied in IGUs, silver-based low-e coatings are generally

located inside the gas-filled and desiccated IGU cavities, and are thus

well-protected from deleterious environmental influences that would

otherwise lead to tarnishing of the silver layers. This enables multidecade service life and has been demonstrated regardless whether the

substrate is glass or a polymer, without the use of protective barrier

coatings, as long as the IGU seal stays intact.

While most high-performance low-e coatings are intended for use

within the IGU (or embedding into a laminate), recent developments

-2.5

-2

-1.5

0

CLR-CLR

-1

-0.5

0

0.5

-2

low-e

Rb*

-4

2-cavity

(Glass)

180-CLR

180-180-CLR

-6

2-cavity

(Heat

180-88-CLR

3-cavity

-8

180-88-88-CLR

-10

Ra*

Figure 2: Reflected Color for various glazing designs

The optics of a low-e coating are determined by the thickness and

index of refraction of the dielectric and silver layers. The color of the

substrate (glass or polymer) also influences the aesthetic characteristics.

Integrating PET-based low-e coatings into an IGU can maintain a more

neutral color (due to the inherent color of the PET and its thinner

cross-section) compared to typical low-e coated soda-lime float glass.

Other Improvements in low-e web coatings

for IGU integration

In order to expand the design variations for IGUs, low-e coatings can

be coated on both sides. This allows different glazing combinations to

­satisfy the “one low-e coating per cavity” design guideline. Also, low-e

coated PET films with lower Tsol or Tvis performance can be used to

increase shading or reduce glare (and consequently a diminishedSHGC). And similar to dual-silver low-e coated glass, multi-silver

low-e stacks are available on PET films. These products improve solar

­selectivity, i.e. they improve the “bandpass” function at the transition

between the visible (high transmission) and near-infrared (high reflection) spectrum.

Cost reduction is another ever-present goal particularly to support

broad adoption of energy-efficient windows, and low-e films can benefit

from the same trends seen elsewhere in the glazing industry: ways to

mitigate the dependence on relatively costly indium for dielectric oxide

layers (by substituting it with zinc and/or tin), fine-tuning the coating

stack and process parameters to improve silver quality and minimize

silver thickness. Cost reductions in the PET substrate are also sought,

52 | SVC Bulletin Summer 2013

2013SummerBulletin1.indd 52

7/9/13 12:22 PM

.1

ce

arthe

e.

ws

nt,

d

d

d

0.5

although many low-cost PET film alternatives have inferior optical and

process performance that prevent market acceptance. Thinner PET

film substrates require improved thermal and web handling control to

suppress heat creases during sputter coating deposition and wrinkling

damage during subsequent winding and slitting operations, and also

pose a challenge for the IGU assembly process to avoid creasing and

wrinkling, requiring special care during film application.

Conclusions

The performance of an economical passive house window with low

U-factor and high SHGC can be achieved with argon-filled triple-cavity

IGUs with a single-silver low-e coating facing each cavity. The thermal

performance of COG is significantly higher than that of the frame and

edge-of-glass, and thus a passive house window benefits from the largest possible glass area. To keep window frames thin, the IGU structure

needs to be as light-weight and compact as possible, favoring multicavity designs that replace center glass panes with suspended low-e

coated polymer films. In the design of low-e coatings, it is essential to

optimize the efficiency of the silver layer through improved deposition

processes in order to achieve the optimum balance between thermal

insulation performance and SHGC. From an optical design perspective,

a stack design that maintains a neutral color irrespective of cavity count

is desirable. Market adoption of advanced energy-efficient coatings is

supported by cost-reduction efforts in the coating stack as well as the

PET substrate.

About the Author

Chris Stoessel

Chris H. Stoessel is a Senior Process Development Manager at Eastman Chemical

Co.’s Palo Alto Advanced Technology Center (Southwall Technologies Inc.) in

Palo Alto, California. He holds a Ph.D. in

Mechanical Engineering (Materials Science)

from the Rheinische Westfälische Technische

Hochschule Aachen (Germany), and conducted

post-doctoral studies under Rointan Bunshah

at UCLA. He has developed thin-film products

and deposition processes for a wide range of

applications such as tribology (via sputtering

and cathodic arc deposition), superconducting

films, optical coatings (at OCLI/JDS-Uniphase),

MEMS, OLED (at DuPont Displays), and

energy-efficient glazing (at Southwall

Technologies/Eastman Chemical Co.).

Chris contributes to the SVC as a co-chair of

SVC’s “Emerging” and “WebTech” TACs, serves

on the Board of Directors, and is Assistant

Program Chair for the 2013 and 2014 SVC TechCons.

For further information, contact Chris Stoessel, Southwall Technologies Inc.,

Palo Alto, CA, at cstoessel@southwall.com

Note: this article is adapted from a 2012 SVC TechCon contribution by

L. Boman, J. Meade, C. Stoessel, R. Wipfler: “Impact of Thin Film Coatings on the

Performance of Highly Energy-Efficient Windows”

Acknowledgments

This research was supported in part by the U.S. Department of Energy

grant DE-EE0003925.

LR

.

n

o

e

r

2. D. Arasteh, S. Selkowitz, J. Apte, and M. LaFrance. 2006. “Zero Energy Windows.”

Proc. 2006 ACEEE Summer Study on Energy Efficiency in Buildings, Pacific Grove, CA

(LBNL 60049)

WITH RF & DC SPUTTERING CAPABILITIES

3. Annual Energy Review 2007, DOE/EIA-0384 (2007), Washington, DC (June 2008)

4. L. Boman, J. Meade, C. Stoessel, R. Wipfler: “Impact of Thin Film Coatings on the

Performance of Highly Energy-Efficient Windows,” 54th Annual Technical Conference

Proceedings of the Society of Vacuum Coaters, p. 452, 2011

5. Lawrence Berkeley National Laboratory: WINDOW 6.3.9.0 (http://windows.lbl.gov/

software/window/6/index.html)

6. Lawrence Berkeley National Laboratory: International Glazing Database 18.0

(http://windows.lbl.gov/materials/IGDB/default.htm)

7. Datasheet published by Bundesverband Flachglas / GMI

8. Y. Tachibana, K. Kusunoki, H. Ohsaki: “Optical properties of Ag/dielectric-material

multilayers”, J. Vacuum, 74 (3-4), pp 555-559, 2004

9. K. Fukuda, S. H.N. Lim, A. Anders: “Coalescence of magnetron-sputtered silver islands

affected by transition metal seeding (Ni, Cr, Nb, Zr, Mo, W, Ta) and other parameters”,

Thin Solid Films, 516 (14), pp. 4546-4552, 2008

10. H. Sahm, C. Charton, R. Thielsch: “Oxidation behaviour of thin silver films deposited

on plastic web characterized by spectroscopic ellipsometry (SE)”, Thin Solid Films,

455-456, pp. 819-823, 2004

11. J.A. Li: “Retro-Fit Low Emissivity Window Films,” 56th Annual Technical Conference

Proceedings of the Society of Vacuum Coaters, 2013 in preparation

c-

STANDARD FEATURES:

Table Top Sputtering System

(20” x 24“ Footprint)

Polished Stainless Steel Chamber

Full Front Door Opening with

View Port

Quartz Crystal Thickness Monitor

Turbomolecular Pumping System

with Matching Dual Stage Rotary

Vane Pump

Full Range Vacuum Gauge

Two 2” Magnetron Sputter Guns

300W RF 13.56 MHz Power Supply

with Automatic Matching Network

600W DC Power Supply

Mass Flow Controllers

115 mm Sample Stage

OPTIONAL FEATURES:

3” Magnetron Sputter Gun

600W RF Power Supply

1200W DC Power Supply

Substrate Rotation

Substrate Heating

RF Biasing

RF Cleaning

Dry Scroll Pump

Water Chiller (Closed Loop Design)

rt

nefit

de

g

Email: torr@ torr.com

www.torr.com

(845) 565-4027

(888) MAC-TORR

Fax: (845) 561-7731

12 Columbus Street; New Windsor, NY 12553

,

1989 - 2011 TORR INTERNATIONAL, INC. ALL RIGHTS RESERVED

ics.

ore

1. Department of Energy, “Recovery Act: Advanced Energy Efficient Building

Technologies”, FOA#: DE-FOA-0000115, 06/29/2009

C

d

References

Summer 2013 SVC Bulletin | 53

2013SummerBulletin1.indd 53

7/9/13 12:22 PM