Special Detailed Requirements Based on Use and Occupancy

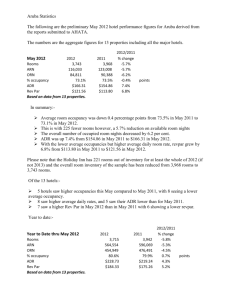

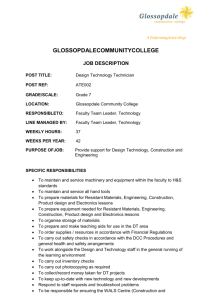

advertisement