Physics: Extended experimental investigation about electricity

advertisement

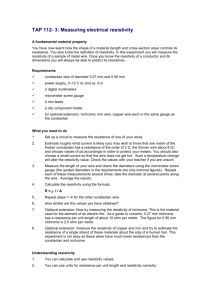

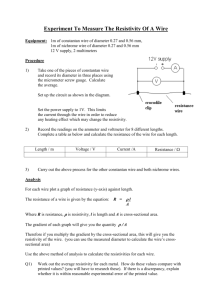

Physics 2007 Sample assessment instrument and indicative responses Extended experimental investigation: Electricity This sample is intended to inform the design of assessment instruments in the senior phase of learning. It highlights the qualities of student work and the match to the syllabus standards. Criteria assessed • Knowledge and conceptual understanding • Investigative processes • Evaluating and concluding Assessment instrument The response presented in this sample is in response to an assessment task. The assessment instrument and annotated response featured in this sample have been altered to better demonstrate to a state-wide audience the features of the assessment technique: extended experimental investigation. The response has been altered to be indicative of student work that would typically match with the syllabus Standard A descriptors. Extended experimental investigation on the topic of electricity. A brief summary of the task provided by the school is presented below. The task sheet has not been included. Refer to the syllabus 7.4.1 for requirements. • Carry out research on the topic. • Write your hypothesis for the investigation. • Decide on a method for the investigation. • Order materials and fill in the Materials Requisition Form and Risk Assessment Form. • Begin the investigation. Record all observations. Modify your experiment if necessary. Gather, record and process data. • Write a scientific report under the headings provided. The journals used by the students have not been included as this is not a requirement of the syllabus. The student response contained appendices. These have not been included. One appendix has been included in the document to show sample calculations from the student appendix. Instrument-specific criteria and standards Indicative responses have been matched to instrument-specific criteria and standards; those which best describe the work in this sample are shown below. For more information about the syllabus dimensions and standards descriptors, see www.qsa.qld.edu.au/1964.html. Knowledge and conceptual understanding Investigative processes Evaluating and concluding 2 | Physics 2007 Standard A Standard C The student work has the following characteristics: The student work has the following characteristics: • reproduction and interpretation of complex and challenging concepts, theories and principles • reproduction of concepts, theories and principles • comparison and explanation of complex concepts, processes and phenomena • explanation of simple processes and phenomena • linking and application of algorithms, concepts, principles, theories and schema to find solutions in complex and challenging situations • application of algorithms, principles, theories and schema to find solutions in simple situations The student work has the following characteristics: The student work has the following characteristics: • formulation of justified significant questions/hypotheses which inform effective and efficient design, refinement and management of investigations • formulation of questions and hypotheses to select and manage investigation • assessment of risk, safe selection and adaptation of equipment, and appropriate application of technology to gather, record and process valid data • assessment of risk, safe selection of equipment, and appropriate application of technology to gather and record data • systematic analysis of primary and secondary data to identify relationships between patterns, trends, errors and anomalies • analysis of primary and secondary data to identify obvious patterns, trends, errors and anomalies The student work has the following characteristics: The student work has the following characteristics: • analysis and evaluation of complex scientific interrelationships • description of scientific interrelationships • exploration of scenarios and possible outcomes with justification of conclusions/ recommendations • description of scenarios and possible outcomes with statements of conclusion/ recommendation • discriminating selection, use and presentation of scientific data and ideas to make meaning accessible to intended audiences through innovative use of range of formats • selection, use and presentation of scientific data and ideas to make meaning accessible in range of formats Sample assessment instrument and indicative responses Indicative response — Standard A The annotations show the match to the instrument-specific standards. Comments Introduction It is proposed that there are factors that influence the extent to which metal wires carry electrical current in circuits i.e. the length of the wire, the crosssectional area of the wire and the type of material in the wire. Several expressions link the factors together. Resistance measured in ohms (Ω) is found by Ohm’s law, R=V/I. V represents voltage, a measure of electrical potential energy and I represents current, a measure of electrons that flow through a circuit. (Wisegeek Organisation 2000). reproduction and interpretation of complex and challenging concepts, theories and principles linking and application of algorithms, concepts, principles, theories and schema to find solutions in complex and challenging situations The student has linked together the expressions related to the investigation. I can be expressed in the derived version of Ohm’s Law (Fig 2). Figure 2 links the relationship between material conductivity (σ), electric field (E) and current density (J) in a basic expression, J=σE (1) Resistivity is a fundamental parameter of a material that describes how easily it can transmit an electrical current. High values of resistivity imply that the material is resistant to the flow of electricity and low values of resistivity imply electrical current is transmitted easily. The derived formula comes from the formula for Resistance, R=V/I, incorporating resistance (R), resistivity (ρ), crosssectional area (A) and length (L). R = L/Aσ = L ρ/A (2) Where ρ = σ Figure 1 Derived formula Length and cross-sectional form a fundamental part of this formula indicating the influential effect it has on resistance (Virtual Institute of Applied Science). The relationship between length (L) and resistance (R) is shown in Figure 2. R α L or R = k L Where k1 = ρ/A (3) (4) Figure 2 Formula linking resistance and length of a conductor Figure 3 shows the inverse relationship present between resistance (R) and cross-sectional area (A) of a wire. R α 1/A or R = k/A (5) (6) Where k2 = L ρ formulation of justified significant questions/hypotheses The initial trial was done to ascertain whether the full investigation was feasible. Figure 3 Formula linking resistance and area of a conductor An initial trial was conducted using a length of copper wire to see the relationship between length and resistance. Copper wire of nominal diameter 1.15mm was used to establish the practicality of using the material, and to test the likely range of resistances. Lengths of 20 cm, 40 cm, 60 cm and 80 cm were used. Queensland Studies Authority September 2012 | 3 Comments Materials Copper wire (1.15mm, nominal), Ohmmeter, crocodile clips, ruler, micrometre screw gauge, sticky tape Assessment of risk and safety management assessment of risk The ohmmeter was a risk since it produced a small electric current. Holding or touching the length of wire being measured was avoided. Rubber soled shoes were worn at all times in order to minimise the risk of electrocution. Water and other conductive metals not associated with the experiment were kept away (A Risk Assessment was completed in the original student work). Method effective and efficient design and management of the investigation. In this response, the results of the initial trials were recorded in the journal. 1. The ohmmeter was configured. The wires and crocodile clips were assembled. The room had a constant temperature. 2. A 20 cm length of copper wire was spread out and measured using a ruler. 3. The length of wire was held taut and flat and crocodile clips were attached to the ends of the wire. 4. An appropriate ohm value on the ohmmeter was set. The reading of resistance on the ohmmeter was then recorded. The setting was 100mA–250Ω. 5. Steps 2–4 were repeated with variable lengths of 40 cm, 60 cm and 80 cm. Results Length +/– 1 mm Resistance +/– 0.1 Ohms Copper Diam (1.15+/– 0.01)mm 200 400 600 800 3.200 6.300 9.400 12.20 Table 1. Measured resistance (on 100mA–250Ω scale) and resistivity values application of technology to gather, record and process data Calculations were done to decide if the data was valid. 4 | Physics 2007 The data in Table 1 was used to create Graph 1. The graphical representations show that the data can be fitted with a straight line, to a correlation factor of 0.9996 for the copper wire. The equation for the best-fitted straight line for the nichrome wire shows an intercept on the vertical axis of 20.6 Ohms, and a slope of 15 Ohms/m. No wires less than 20 cm in length were used. Resistivity values The resistivity values (ohm.m) of the materials used: Copper Nichrome Aluminium Steel –8 1.68 x 10 –6 –6 –6 1.1 x 10 to 1.5 x 10 (value of 1.0 x 10 taken in this investigation) –8 2.83 x 10 values vary due to composition Sample assessment instrument and indicative responses Comments The trial data has been presented to make meaning accessible to the intended audience Resistance (milli ohms) Resistance vs. length 14 12 10 8 6 4 2 0 y = 15.05x + 0.25 R² = 0.9994 Copper wire 1.15mm Linear (Copper wire 1.15mm) 0 0.5 Length of wire (m) 1 Linear (Copper wire 1.15mm) Graph 1 Resistance values for Copper 1.15 mm Discussion effective and efficient design, refinement and management of investigations An initial problem was the meters were supplied with probes that could not be easily attached to the lengths of wire. Pieces of wire with an alligator clip on each end were available. These could be clipped from the probes to the end of the copper wire. The copper wire was insulated with a clear covering. When the alligator clips were attached to the wire, there was no reading on the meter. The ends of the wire were rubbed with a small file and then with sand-paper so as to give a clean metal surface to ensure a good contact with the clips. These wires of the probes and alligator clips have a resistance, and would need to be subtracted from the measurement of the total resistance to give the resistance of the copper wire that was to be measured. The alligator clips were clipped together, so that the resistance of the wires of the probes and alligator connections could be measured. However the result was not reliable nor consistent. Moving the wires of the circuit, and trying to hold the clips hard together gave results which varied from 45 Ohms to less than 1 Ohm. However, when the ends of the copper wire were clipped to the meter, the meter gave a steady display. The resistance for each of the various lengths of copper wire and of the nichrome wire was measured, so that a graph could be produced to see if the result was linear. formulation of justified significant questions/hypothes es which inform effective and efficient design, refinement and management of investigations From the results, clear trends and relationships were apparent. The value of the correlation factor close to Unity shows that with a high degree of statistical significance, the data is linear. The trends in the data thus support the hypothesis that resistance varies linearly with length, for any metal. From Equation 3, k1 is the slope of the graph of R vs. L. Further experiments with different metal wires were considered. Data for resistance found in the initial trials was used in further trials. The wires used were considered to be of a consistent diameter throughout the length. Queensland Studies Authority September 2012 | 5 Comments Hypothesis If the length of a wire is increased then its resistance will increase if its cross-sectional area and temperature remains constant. If the cross-sectional area increases then the resistance of a conductor will decrease if its length and temperature remain constant. effective and efficient design, refinement and management of investigations Method Wire lengths (independent variable) of 20 cm, 40 cm, 60 cm and 80 cm were used across four different wires (copper, nichrome, aluminium and steel) in recording resistance (dependent variable), due to their prevalence and common use. The longer lengths of wire were measured before the shorter lengths. Results Measured resistance (on 100mA–250Ω scale) Material appropriate application of technology to gather, record and process valid data Diameter (mm) Crosssectional area 2 (mm ) 20 cm length 40 cm length 60 cm length 80 cm length copper 0.49 0.1886 15.3 29.3 43.0 59.3 copper 1.15 1.0387 3.20 6.30 9.36 12.2 nichrome 0.3 0.0707 1882 3756 5630 7575 nichrome 0.43 0.1452 1320 2660 4016 5133 nichrome 0.65 0.3318 577.0 1115 1649 2220 nichrome 0.87 0.5945 300.0 611.1 887.0 1170 aluminium 1.05 0.8659 9.45 19.7 30.9 40.6 steel 1.1 0.9503 22.4 47.0 74.3 99.4 Table 2 Measured resistance (on 100mA–250Ω scale) and resistivity values (The values for nichrome and steel have been shaded for ease of reference.) Length (cm) and Unit of reading 20 Theoretical resistance linking and application of algorithms, concepts, principles, theories and schema to find solutions in complex and challenging situations 6 | Physics 2007 3.2348x10 40 –7 6.4696x10 60 –7 9.7045x10 80 –7 1.2039x10 –7 Ω Measured resistance 3.20 6.30 9.36 12.2 0.58 2.68 3.69 6.07 100mA–250Ω % error –8 Table 3 Values for Copper (resistivity =1.68x10 ), 1.15 mm diameter, cross-sectional 2 area =1.038689m (These values were chosen as they give a value for the resistivity of copper from experimental data that is close to the theoretical value.) Sample assessment instrument and indicative responses Comments Resistance vs. length y = 73.265x + 0.005 R² = 0.9987 60 50 40 Cu 0.49mm 30 Cu 1.15mm y = 15.006x + 0.266 R² = 0.9996 20 10 Linear (Cu 0.49mm) Linear (Cu 1.15mm) 0 0 0.5 Length (m) 1 Graph 2 Resistance versus length for Copper wire Resistance vs. length 8000 y = 9476.5x - 27.5 R² = 0.9999 7000 Resistance (milli ohms) discriminating selection, use and presentation of scientific data and ideas to make meaning accessible to intended audiences through innovative use of graphs Resistance (milli ohms) 70 nichrome 0.3mm nichrome 0.43mm 6000 y = 6397.5x + 83.5 R² = 0.9981 5000 nichrome 0.65mm nichrome 0.87mm 4000 y = 2731.5x + 24.5 R² = 0.9998 3000 2000 Linear (nichrome 0.3mm) Linear (nichrome 0.43mm) 1000 0 0 0.2 y = 1443x + 20.5 R² = 0.9993 0.4 0.6 0.8 1 Length (m) Linear (nichrome 0.65mm) Linear (nichrome 0.87mm) Graph 3 Resistance versus length for Nichrome wire. Queensland Studies Authority September 2012 | 7 Comments discriminating selection, use and presentation of scientific data The data for copper has been used as an example here as the recorded results are very close to theoretical results Diameter of wire (mm) Cross-sectional area 2 (mm ) Slope of line Calculated resistivity (ohm.m x 10) 0.3 0.0707 9476.5 0.6698 0.43 0.1452 6397.5 0.9288 0.65 0.3318 2731.5 0.9060 0.87 0.5945 1443 0.8577 Table 4 Calculated values of resistivity of Nichrome wire. Resistance vs. crosssectional area comparison and explanation of complex concepts, processes and phenomena Resistance (milli ohms) 6000 5000 4000 nichrome 20cm 3000 nichrome 40cm 2000 nichrome 60cm 1000 nichrome 80cm 0 0 0.2 0.4 0.6 0.8 Cross-sectional area (mm2) Graph 4 Resistance versus cross-sectional area for nichrome wires. 8 | Physics 2007 Sample assessment instrument and indicative responses Comments 6000 Resistance vs. 1/Cross-sectional area Resistance (milli ohms) y = 764.06x - 125.48 R² = 0.9996 5000 nichrome 20cm nichrome40cm 4000 y = 607.31x - 173.89 R² = 1 nichrome 60cm 3000 nichrome 80cm y = 397.39x - 80.869 R² = 1 2000 Linear (nichrome 20cm) 1000 0 0 y = 196.25x - 29.601 R² = 0.9993 2 4 6 8 1/Cross-sectional area (106 m-2) Linear (nichrome40cm) Linear (nichrome 60cm) Graph 5 Resistance versus 1/Area for nichrome wires comparison and explanation of complex concepts, processes and phenomena Discussion Clear trends and relationships were apparent. The data in Graphs 2 and 3 shows a linear relationship with a high confidence level by the correlation factor of greater than 0.999 in each case. It is evident from Graph 3 that as length increased so did resistance. This is shown by a 20 cm length of nichrome wire (0.87mm) that had a resistance of 300.0 100mA–250Ω. When the length is increased by 60 cm a resistance of 1170 100mA–250Ω was recorded. This value was nearly four times larger than the original value. The other wires yielded a similar relationship. The value of resistance was found to be directly proportional to length. This means the shorter the length of wire, the smaller the resistance. The formula R = 1443L + 20.5 (Graph 3) was found for the nichrome (diameter 0.87mm) wire for example. The value of the constant in the linear function of R = f (L) does vary for each sample metal. The results about resistance and resistivity cannot be interpreted when comparing different metals and different alloys when the materials used vary so greatly in resistivity as shown in Table 2. Queensland Studies Authority September 2012 | 9 Comments Table 2 data has several inconsistencies. The calculated resistivity for copper (0.49mm) is not close to the value calculated for the copper of 1.15 mm diameter. The resistivity values for the 1.15 mm copper are close to the theoretical value at 0 room temperature (20 C). Table 4 shows the resistivity values for nichrome calculated from the values in Graph 3.The calculated values for resistivity for nichrome show variation. The values for the 0.3 mm wire are below the theoretical –6 value of 1.0 x 10 ohm.m. The values for the other three lengths are within normal experimental accepted errors. Inconsistent results have resulted when using the two thinnest wires, copper 0.49 mm and nichrome 0.3 mm. The assumption has been made that the wires have a consistent diameter throughout the length but this is probably not the case. The thinner wire may heat up more easily with current flow. The measurement of the diameter also had to be exact. It is difficult to ascertain if the values for steel are like the theoretical values as there are done to compare with. The values in Table 2 for steel are however consistent. The values jn Table 2 for aluminium are consistent but are less than half the theoretical value above. An oxide can form on the outside of aluminium which may have affected its conductive properties in the investigation. The resistance for the 60cm length of nichrome wire (0.65 mm) is inconsistent with the other readings for that length and was disregarded. systematic analysis of primary and secondary data to identify relationships between patterns, trends, errors and anomalies linking and application of algorithms, concepts, principles, theories and schema to find solutions in complex and challenging situations 10 | Physics 2007 Table 3 shows the theoretical values of resistance were calculated for the copper wire (1.15 mm diameter). When compared with the actual measured value (by ohmmeter) little variation was seen. When 20 cm, and other values (Sample calculation 1) were substituted into the equation (Figure 2) a resistance of 3.235 100mA–250Ω was calculated, deviating only 0.1352 100mA–250Ω from the measured value of 3.216 100mA–250Ω, equivalent to an error of 0.59%. This indicated the approximate accuracy of this equation. Graph 2 showed a slight amplification of this error over an increase in length. This variation was minimal. The correlation between calculated and theoretical values backs up the reliability of this data. This linear and uniform data showed no major anomalies. Cross-sectional area was calculated by using the formula for area (sample calculation 3) by substituting the radius of the wire. A nichrome wire with cross2 sectional area of 0.07 mm had a resistance of 1882 100mA–250Ω as opposed to a 2 nichrome wire with and area of 0.59 mm that had a resistance of 299.8 100mA– 250Ω. Graph 2 compared the resistance values measured for the two lengths of copper. As stated, the smaller diameter wire gave unreliable data. Graph 5 compared the nichrome wires investigated. Graphs 4 shows that as the cross-sectional area of the nichrome wires increased the resistance decreased. Graph 5 shows how the value of resistance inversely affected the value of cross-sectional area over a consistent wire. 2 An R of 0.99 confirmed how this data followed linear and predictable trend. Several factors may have affected the measured values of resistance. The variation of electrical activity between different metals in contact also occurs in the study of electro-chemistry (Smith 1996), and the effect of contact-potentials between different metals could be a factor when measurements with the small currents (milli amps) of an ohmmeter produce small voltages (milli volts) in the sensing circuit when the contact voltages maybe of the same size. It proved difficult to compare metals and alloys e.g. steel and copper. Steel and nichrome did not have exact theoretical values for resistivity for comparison. The use of very narrow diameter wires did not give reliable results as stated. Sample assessment instrument and indicative responses Comments Sources of error include: • The limitations of the micrometre and ohmmeter instruments affecting the precision of the recorded values. • Human error in measuring due to parallax readings. • The use of a ruler to measure in centimetres. • The calibration of the micrometre which was not done by a professional. • Measurements made within seconds of each other, causing heating of the wire, resulting in higher readings. Recommendations To alleviate errors in future changes could be made in the design and methodology. The method showed several flaws when attempting to measure small resistances. A different method may be to pass a small current through the circuit, from a voltage source of known size, and use a separate voltmeter to measure the electrical potential difference (i.e. a voltage) across the ends of the wire that is being tested, and use Ohms law to calculate the resistance. The temperature would have to be held constant so that any heating effects of the current would be controlled. exploration of scenarios and possible outcomes with justification of conclusions/ recommendations Fully stretching out the wire and pulling it taut to decrease the number of deformities and bends could improve the accuracy of results. If a measurement is to taken for a 20 cm length then a 25 cm length should be cut and the crocodile clips placed exactly at the 20 cm length. In this way the exact length is obtained. Lengths from 20 cm to 80 cm (at 10cm intervals) could be investigated in future investigations. The material of the clips could be investigated. Waiting for the wire to cool after each ohmmeter measurement could have reduced thermal resistance. Measuring the wire with the ruler at eye level could eliminate parallax error. Measuring the length at 5 cm intervals or measuring more diameters may have given a wider spread of results and improve accuracy of the graphical equations. Wires of equal diameter could be used e.g. 1mm or larger as the results have shown that very thin wires do not give reliable results. Wires of known composition (metals and alloys) are best to use in future to allow comparison. A further investigation could use the same lengths but deliberately place kinks in the wire to see the effect on resistance values. Conclusion The results supported the key relationships predicted, showing that when length increased so did resistance. When cross-sectional area increased, resistance decreased. It was concluded that a linear relationship existed between resistance and length and that an inverse proportional relationship existed between resistance and cross-sectional area. Queensland Studies Authority September 2012 | 11 Comments Reference list “Dependence of Resistance on Cross-sectional Area.” Virtual Institute of Applied science Web. 26 Aug 2011. <http://www.vias.org/physics/example 4 5 04.html> “Factors affecting Resistance, Electricity, Science Help. Online Science TutoringITutorvista.com. “Tutorvista.com – Online Tutoring, Homework Help for math, Science, English from best Online Tutor. Web. 18 Aug 2011. http://www.tutorvista.com/content/science/science-ii/electricity/factors-affectingresistance.phg “GCSE Physics: Resistance and Area.” GSCE.com Revising Revision. Web. 26 Aug 2011. http://www.gcse.com/vary4b.htm “How is Electrical Resistance Measured?” WiseGEEK: Clear Answers for Common Questions. 18 Aug 2011. http://www.wisegeek.com/how-is-electrical-resistancemeasured.htm. “Physics Zone: Resistance in a Conductor.” Oswego City School District Regents Exam Prep Center. Web. 26 Aug 2011. <http://regentsprep.org/Regents/physics/phys03/bresist/default.htm> “Resistance and Resistivity” Web. 26 Aug 2011. <http://hyperphysics.phyastr.qsu.edu/hbase/electric/resis.html> “Resistance of Conductors.” Martin’s World. Web. 16 Aug 2011. <http://www.marts100.com/resistance.htm> “Resistance.” The Physics Classroom. Web. 26 Aug 2011. <http://physicsclassroom.com/class/circuits/u9l3b.cfm> “SparkNotes: SAT Physics: Resistance.” SparkNotes: Today’s Most Popular Study Guides. Web 26 Aug 2011. http://www.sparknotes.com/testprep/books/sat2/physics/chapter14section3.rhtml Smith Roland, “Exploring Chemistry” (1996). 12 | Physics 2007 Sample assessment instrument and indicative responses Comments Appendix Sample calculation 1 Finding theoretical resistance R = L ρ/A R=? L = 0.2 ρ = 1.68 E–8 A = 1.038689m 2 R= 0.2 x 1.68 E–8 /1.038689 linking and application of algorithms, concepts, principles, theories and schema to find solutions in complex and challenging situations R= 3.23485 x10 Ω –9 Sample calculation 2 Finding percentage error Calculated R = 3.216 x10 Ω Theoretical R = 3.23485 x10 Ω % difference = (recorded – theoretical)/theoretical x 100 = (3.216–3.23485)/ 3.23485 x 100 = 0.5827% –9 –9 Sample calculation 3 Finding area (Graph 6) A = πr diameter = 0.87 mm 2 A = π(0.435) 2 A = 0.594 mm 2 radius = 0.435 mm Sample calculation 4 Calculating inverse area (Graph 7) 2 A = 0.594 mm R = 1/A R = 1/0.594 –7 2 = 3.4 x10 m Sample calculation 5 2 A = 0.14522 mm k = 6397.5 (from graph 5) ρ=kA = 6397.5 x 0.14522 –6 = 0.929 x 10 ohm.m Queensland Studies Authority September 2012 | 13 Student response — Standard C Comments Introduction In this report the following question was looked at: “how do different wires and different widths affect current and resistance in wires?” Resistance is the property of a component which restricts the flow of electric current (http://www.kpsec.freeuk.com/resistan.htm). An object with low resistance is called a conductor. A conductor has free valence electrons which mean that the electrons have free movement between each molecule. The further away from the nuclei the valence electrons are the more movement they have causing a greater conductance. reproduction of concepts, theories and principles formulation of questions and hypotheses to select and manage investigations Figure 1 Diagram of electrons around a nucleus. (Diagram removed due to copyright issues.) There are a few things that affect the resistance of an object. Length affects the resistance where the longer the electrons have to travel the higher the resistance. Whilst the greater the cross sectional area the less resistance there is (http://hyperphysics.phy-astr.gsu.edu/hbase/electric/resis.html). The temperature affects it where the higher temperatures causes more heat which then in turn causes the nuclei to vibrate more then it collides with the electrons more frequently. Resistivity is defined as ‘the ability of a material to resist electrical conduction’ (http://www.glossary.oilfield.slb.com/Display.cfm?term=resistivity). Resistivity is dependent on the material that is used. “It was found that by increasing the wires length and width the resistance would increase, whilst at the same time the resistance relied heavily on what properties the material had. To prove that this was right the experiment below was designed where the different resistance at different lengths, widths, and, materials and then compared. The idea of if the length of the wire is increased (from 10cm) the resistance will increase, and if the material is changed then the resistance will change depending on the metal’s properties, was looked at in depth in this experiment. To do this the resistance had to be recorded at different lengths, widths, and resistivity. Hypothesis If the length of the wire is increased (from 10cm) the resistance should increase, and if the material is changed then the resistance should change depending on the metals’ properties. Method manage investigations 14 | Physics 2007 The wire’s width and length was measured, and was recorded. The alligator clips were attached at two points that were specific lengths apart measured previously. The resistance was then measured by the use of an ohmmeter and the results were recorded. This was repeated with all the wires. Sample assessment instrument and indicative responses Comments assessment of risk Safety Cutting tools were used to cut the wires. To minimise the chances of students cutting themselves the wires were cut by one student per group. The microohmmeter used 10 Amps which involved a low voltage, and it was a heavy object. To minimise the chances of students hurting themselves by dropping the microohmmeter on their feet it was placed in one spot for the whole time the experiments were being done. Modifications The insulated wires were not used because getting a proper reading could not be done. Nickel, iron, zinc, silver, lead and graphite were dropped because it was not available to use. Constantant and nichrome wires were added because they were available to use. Did not read the temperature because it was too hard to do properly. Instead of getting the results of different lengths on one wire only, the different lengths were done on all wires. Results Table 1 Resistance and Resistivity values Resistance (milli ohms) Length (cm) Material and width (mm) application of technology to gather, record and process data application of algorithms, principles, theories and schema to find solutions in simple situations 10 20 30 Calculated Average Resistivity Value (ohm.m) Theoretical Resistivity Value (ohm.m) 40 –8 1.68x10 –8 –8 1.68x10 Copper (0.58) 6.54 12.78 19.78 25.54 1.727x10 –8 1.6883x10 –8 1.7420x10 –8 1.6869x10 –8 Av =1.7111x10 Copper (1.28) 1.33 2.49 3.66 4.96 1.710x10 –8 1.706x10 –8 1.6703x10 –8 1.6077x10 –8 Av = 1.6735 x10 Aluminium (1.22) 2.52 5.10 6.90 9.34 2.9412x10 –8 2.9833x10 –8 2.6887x10 –8 2.7296x10 –8 Av = 2.8357 x10 Constantant 42.50 (1.2) 84.86 127.3 169.7 48.07 x 10 49x10 –8 47.98x10 –8 49.76x10 –8 47.799 x10 –8 Av = 48.4023x10 Nichrome (0.91) 246.6 443.1 592.2 99.99x10 110x10 –8 80.189 x10 –8 96.062 x10 –8 96.289 x10 –8 Av = 93.1325x10 153.8 –8 –8 2.65x10 –8 –8 –8 –8 –8 Queensland Studies Authority September 2012 | 15 Comments Resistance vs. length Resistance (milli ohms) selection, use and presentation of scientific data and ideas to make meaning accessible 30 y = 64x + 0.16 R² = 0.9987 25 Copper 0.58mm 20 Copper 1.28mm 15 y = 12.06x + 0.095 R² = 0.9992 10 5 Linear (Copper 0.58mm) 0 Linear (Copper 1.28mm) 0 0.2 0.4 Length (m) 0.6 Graph 1 Resistance versus length for Copper wire. Resistance (milli ohms) Resistance vs. length 10 y = 22.26x + 0.4 R² = 0.9958 8 6 Al 1.22mm 4 Linear (Al 1.22mm) 2 0 0 0.2 0.4 Length (m) 0.6 Graph 2 Resistance versus length for Copper wire. Resistance (milli ohms) Resistance vs. length 200 150 y = 424.09x + 0.065 R² = 1 100 Constanant 1.2mm 50 Linear (Constanant 1.2mm) 0 0 0.2 0.4 Length (m) 0.6 Graph 3 Resistance versus length for Constanant wire. 16 | Physics 2007 Sample assessment instrument and indicative responses Comments Resistance vs. length analysis of primary and secondary data to identify obvious patterns and trends Resistance (milli ohms) 700 y = 1511.9x - 19.055 R² = 0.9834 600 500 400 Nichrome 0.91mm 300 Linear (Nichrome 0.91mm) 200 100 0 0 0.2 0.4 Length (m) 0.6 Graph 4 Resistance versus length forNichrome wire. Discussion reproduction of concepts, theories and principles Using the following equation it can be found that the resistance is resistivity by length divided by the cross sectional area (width). (http://hyperphysics.phy-astr.gsu.edu/hbase/electric/resis.htm) Rearranging the equation it can be seen that resistivity is resistance by width divided by length. To find the resistivity of the copper wire with width of 0.58cm so a cross-area of 0.2642, length of 0.1 meters and resistance of 6.538 milli ohms –8 which equals 1.727x10 ohms m. According to the data it can be concluded that the width, length and resistivity affects the resistance where the wider the wire the less resistance, the longer the wire the more resistance and the higher the resistivity the higher the resistance. These conclusions were made because Table 1 shows how the length and resistivity increased the resistance whilst the area (copper 0.58 and copper 1.28) decreased the resistance. identify obvious errors While conducting this experiment some errors were made because the measuring of the length was only done in centimetres, the width in millimetres and the resistance in milli ohms. An anomaly was found where the average resistivity of the two copper wires was expected to be the same but found that the two wires with different widths had different resistivity. This could be from the fact that even though the two wires are made out of the same materials the materials themselves could have impurities in them changing the property. To fix this in a future experiment the wires would have to be made sure they were pure. Queensland Studies Authority September 2012 | 17 Comments The Graphs 1–4 show a result that would be expected where the length increase in a set amount each time so does the resistance in a linear form in proportion to the amount increased and the resistivity. The calculated resistivity and the graph of resistance vs. length with Nichrome (Graph 4) had results that were not expected. Where the resistivity decreased greatly from 10cm to 20cm and then increased by a considerable amount from 20cm to 30 cm and then only decreased slightly from 30cm to 40cm. description of scenarios and possible outcomes with statements of conclusion/ recommendation Part of the reason for this anomaly could be because the wire was slightly bent at certain areas even after it was straightened meaning that the length that were measured would be slightly off which has a greater effect on the resistance when the wire has a high resistivity such as nichrome has. The other reason is because the resistance is so high the error is going to be greater but still within the error range. Whilst conducting the experiment the wires were knocked sometimes changing the resistance value. If this experiment was to be done again it is recommended that the wires be measured in millimetres and the wires are placed onto the table every time it is measured instead of being held. And the wires are fully straightened and not bent in any way. Conclusion The aim was to find out how resistance was affected when the resistivity, length of wire and width of wire, were change about. This aim was achieved. It was found that when you increase either the length or resistivity the resistance increased but increasing the width decreased the resistance of the wire. The wires should have been placed on the bench every time and the length measured up to nearest millimetre instead of centimetre. Acknowledgments The QSA acknowledges the contribution of St Joseph’s College Gregory Terrace in the preparation of this document. 18 | Physics 2007 Sample assessment instrument and indicative responses