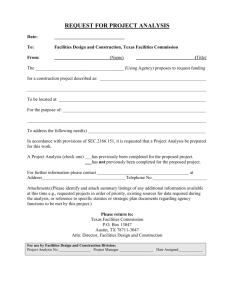

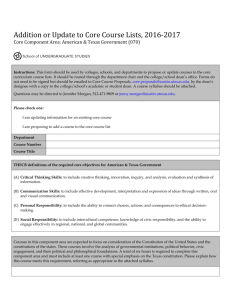

SEMI Texas Spring Forum

advertisement

SEMI Texas Spring Forum Outline Industry Roadmap / Concerns Supply Chain Issues Manufacturing Challenges Human Resource Needs 2 Industry Roadmap: Foundry Business Who is missing from this chart? 3 Industry: Convergence Competition Begins STMicroelectronics has selected Samsung's foundry business unit for the production of ICs using a 32/28nm high-K metal gate manufacturing process. Intel Corp has agreed to make chips on behalf of Altera, a significant step toward opening its prized manufacturing technology to customers on a larger scale, potentially including Apple. 4 Industry: The Race to 14nm Will the field of competitors become limited? 5 Industry: The Race to 14nm What size investment will next generation of FAB be? How will we manage capital cost at this speed? 45nm 32nm When do you go to 450mm? 28nm New Materials / New Tools 20nm EUV Litho? 14nm 5 year depreciation on Tools 6 Samsung Austin Supply Chain City Water Electricity Natural Gas Propane & Diesel Chemicals Gases Targets/Pads PCB Boards Motors/Robots Filters Water 1 Facilities SAS OPERATIONS Energy Product 4 Raw Materials 243 Parts 7490 Waste Fab Process 7 Global Supply Risks: Helium He is a byproduct of Natural Gas – Lower demand = less He Helium Federal Helium Reserve – “Bush Dome” Federal Helium Program developed in 1917 Generates 50% of world He supply 35% is in the Amarillo “Bush Dome” – BLM (Bureau of Land Management) – Wants to get out of selling He Amarillo, TX 8 Regional Supply Chain Optimization Required Localize – Reduce logistics complications and delivery risks Maximize supply sources – Parts cleaning, repairs, construction, machining, etc. Reduce energy requirements – Global energy demand, local effluents, increased energy costs Reduce water requirements – Texas is in a state of drought, driving up water supply concerns Sustainability! 9 Samsung Austin Specific What we are seeing or worrying about: Transporting of clean parts – Plastic bags are not good at 20nm Chemicals – All must improve in quality – Requires us to improve our filter technology. More waste? – Cleans seems to be the fastest solution but creates more waste. 10 Manufacturing Challenges Process complexity – New materials – New equipment – 3D technology Numerous work-arounds and lost productivity – Double patterning – Additional cleans – Increased PMs 11 HR: Workforce Solutions Engineering Technicians Employee Referrals Employee Referrals Hourly Hires Referrals from current employees Referrals from current employees Operators: train, evaluate, hire Location Interviews Job Fairs Target talent Sponsored open call Austin/Dallas/San Antonio/Phoenix/etc. Supervisors: promote from within CORP program Hire new college graduates from top universities from Texas & around US Military Hires Mfg Marketing of Jobs Navy Nukes/Submarine most effective Social Media Military Hires School Affiliations PR Ad’s & Video Sponsor H1B Visa’s ACC Apprenticeship program Placed in related magazines/social media ITT Tech relationship Texas Workforce Commission FaceBook/LinkedIn/Twitter 12 HR: Cultivation Technical Forums STEM Day at SAS Scholars Program High Tech U, SEMI Educational Reimbursement E3 Alliance Conference attendance Communities in Schools Engineering Institute at SAS Austin Workforce Commission Educational Reimbursement at SAS Tech Institute Texas State BOD ACC Apprentice Technician Program Texas State Women in Engineering Conference UT BOD Engineering Fraternity/Sororities support UofH Relationship 13 Quality Is “World’s Best” possible? What does that look like? Cost Create and deliver value Quality How do we build high value at a low cost? Productivity How do we improve the efficiency of the Supply Chain? Quality – Part of the core framework Family – Work Life balance Learning – Engineering/Leadership training Teamwork Integrity Respect Team members’ acceptance of personal responsibility for meeting their goals, commitments, and promises. 14