HVAC Acoustic Fundamentals

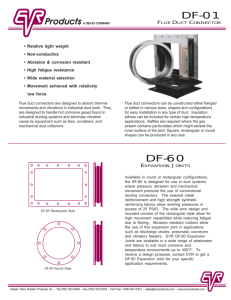

advertisement