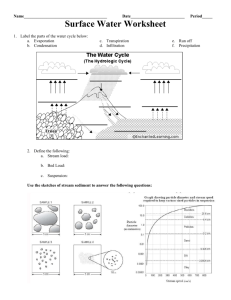

Chapter 6 – Stream Hydraulics - NRCS

advertisement