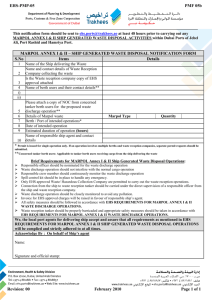

The Revisions to MARPOL Annex II

advertisement