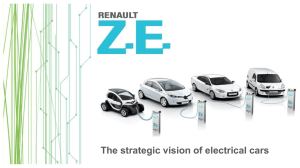

Recommended Renault equipment Sector: Electricity

advertisement