Buildings are often constructed on sites where volatile organic compounds (VOC) are

present in the ground. This publication provides guidance on the use of plastic

membranes to reduce vapour migration into buildings. It discusses vapour transport

mechanisms that occur in membranes, factors that influence this and the test methods

available for determining the rate of vapour permeation. It then explains how to use the

results in a risk assessment. Durability and resistance to damage when plastic

membranes are exposed to VOCs is a concern and the guide considers the potential for

degradation and which test methods are suitable to assess performance. This guide

should allow readers to make a robust evaluation of the contribution to membranes to

reducing indoor inhalation risk from VOCs in the ground and to specify the most

appropriate type of membrane for any given site.

C748

9 780860 177531

© Copyright CIRIA 2015. No unauthorised copying or distribution permitted. For use by Triton Systems only.

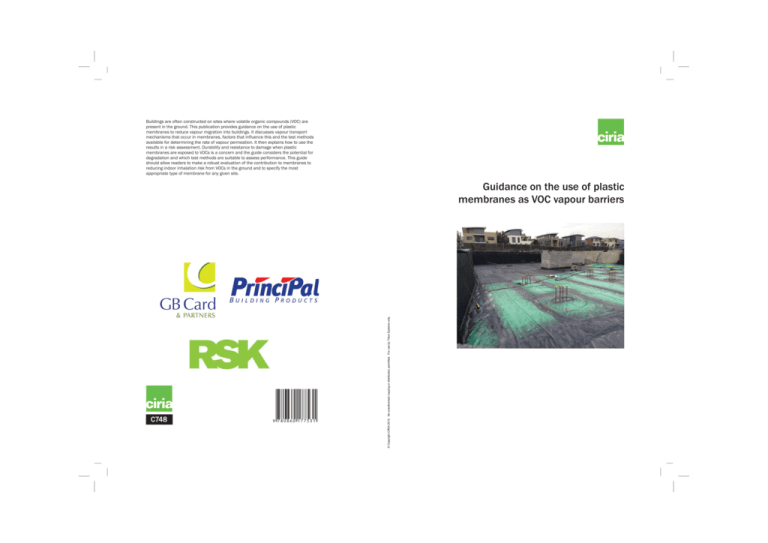

Guidance on the use of plastic

membranes as VOC vapour barriers

Who we are

Established in 1960, CIRIA is a highly regarded, industry-responsive, not for profit research and information

association, which encompasses the construction and built environment industries.

CIRIA operates across a range of market sectors and disciplines, providing a platform for collaborative projects

and dissemination by enhancing industry performance, and sharing knowledge and innovation across the built

environment.

As an authoritative provider of good practice guidance, solutions and information, CIRIA operates as a knowledgebase for disseminating and delivering a comprehensive range of business improvement services and research

products for public and private sector organisations, as well as academia.

How to get involved

CIRIA manage or actively participate in several topic-specific learning and business networks and clubs:

zzCore

membership

zzCEEQUAL

Allows your employees to assist with the development of

and access to good practice guidance, formal networks,

facilitation, conferences, workshops and training.

zzAssociate

membership

zzLACL (Local

Allows your employees to access CIRIA’s services.

Members are able to access exclusive content via the

CIRIA website.

zzCIRIA

© Copyright CIRIA 2015. No unauthorised copying or distribution permitted. For use by Triton Systems only.

CIRIA Network

(European Marine Sand and Gravel Group)

CIRIA provides secretariat support to EMSAGG, including

management of the Group’s conferences, workshops and

website and producing its newsletter.

zzLANDFoRM

A member-based community where clients and professionals

meet, develop and share knowledge about specific topics

relevant to construction and the built environment.

zzProject

Authority Contaminated Land Network)

LACL helps local authorities address responsibilities

under Part IIA of the Environmental Protection Act 1990.

zzEMSAGG

Books Club

Members can buy most CIRIA publications at half price and

can attend a range of CIRIA conferences at reduced rates.

zzThe

CIRIA co-manages this environmental award scheme,

which promotes environmental quality in civil engineering

and infrastructure projects.

funding

(Local Authority Network on Drainage

and Flood Risk Management)

A platform for sharing knowledge and expertise in flood

risk management and sustainable drainage.

zzBRMF

Project funders influence the direction of the research

and gain early access to the results.

(Brownfield Risk Management Forum)

Promoting sustainable and good practice in brownfield

projects in the UK.

Where we are

Discover how your organisation can benefit from CIRIA’s authoritative and practical guidance – contact us by:

Post

Griffin Court, 15 Long Lane, London, EC1A 9PN, UK

Telephone

+44 (0)20 7549 3300

Fax

+44 (0)20 7549 3349

Email

enquiries@ciria.org

Websitewww.ciria.org

(for details of membership, networks, events, collaborative projects and to access CIRIA publications through

the bookshop)

CIRIA C748

London, 2014

Guidance on the use of

plastic membranes as

VOC vapour barriers

© Copyright CIRIA 2015. No unauthorised copying or distribution permitted. For use by Triton Systems only.

S Wilson EPG Ltd

S Abbot TCNF Ltd, and University of Leeds

H Mallett BuroHappold Engineering

Griffin Court, 15 Long Lane, London, EC1A 9PN

Tel: 020 7549 3300

Fax: 020 7549 3349

Email: enquiries@ciria.org

Website: www.ciria.org

Summary

Buildings are often constructed on sites where volatile organic compounds (VOC) are present in the

ground. This publication provides guidance on the use of plastic membranes to reduce vapour migration

into buildings. It discusses vapour transport mechanisms that occur in membranes, factors that influence

this and the test methods available for determining the rate of vapour permeation. It then explains how

to use the results in a risk assessment. Durability and resistance to damage when plastic membranes are

exposed to VOCs is a concern and the guide considers the potential for degradation and which tests

methods are suitable to assess performance. Physical damage during and after installation can also occur

and the guide identifies the key performance properties that should be specified to minimise the risk of

defects. This guide should allow readers to make a robust evaluation of the contribution to membranes

to reducing indoor inhalation risk from VOCs in the ground and to specify the most appropriate type of

membrane for any given site.

Guidance on the use of plastic membranes as VOC vapour barriers

Wilson, S, Abbot, S, Mallett, H

CIRIA

C748

RP960

© CIRIA 2014

ISBN: 978-0-86017-753-1

British Library Cataloguing in Publication Data

A catalogue record is available for this book from the British Library

Keywords

© Copyright CIRIA 2015. No unauthorised copying or distribution permitted. For use by Triton Systems only.

Contaminated land, environmental management, ground engineering, materials sustainability

Reader interest

Classification

Hazardous ground gases, membrane and other

barriers, VOC vapours

Availability Open publication

Content

Advice/guidance, case study

Status

Committee-guided

UserConsultants, contractors, local authority

regulators, house builders, clients

Published by CIRIA, Griffin Court, 15 Long Lane, EC1A 9PN, UK

This publication is designed to provide accurate and authoritative information on the subject matter covered. It is sold and/or

distributed with the understanding that neither the authors nor the publisher is thereby engaged in rendering a specific legal or any

other professional service. While every effort has been made to ensure the accuracy and completeness of the publication, no warranty

or fitness is provided or implied, and the authors and publisher shall have neither liability nor responsibility to any person or entity

with respect to any loss or damage arising from its use.

All rights reserved. No part of this publication may be reproduced or transmitted in any form or by any means, including photocopying

and recording, without the written permission of the copyright holder, application for which should be addressed to the publisher. Such

written permission must also be obtained before any part of this publication is stored in a retrieval system of any nature.

If you would like to reproduce any of the figures, text or technical information from this or any other CIRIA publication for use

in other documents or publications, please contact the Publishing Department for more details on copyright terms and charges at:

publishing@ciria.org Tel: 020 7549 3300.

Front cover courtesy CETCO

ii

CIRIA, C748

Acknowledgements

This publication is the result of additional work carried out under CIRIA Research Project 960. It has

been written by Steve Wilson, EPG Ltd, Stephen Abbott, TCNF Ltd, and Hugh Mallett, BuroHappold

Engineering, under contract to CIRIA.

Authors

Steve Wilson MSc BEng CEng CSci MICE MCIWEM FGS

Steve is a chartered engineer and environmentalist with over 25 years’ experience of geotechnical and

environmental engineering. Steve is a well-respected specialist on the assessment of gassing sites and has

written several key technical papers on this subject. He has contributed to CIRIA, British Standards and

CIEH guidance on ground gas assessment.

Steven Abbot BSc PhD Fellow RSC

Professor Steven Abbott has a PhD in chemistry from Oxford/Harvard and was a post-doc researcher in

the Nobel prize winning laboratory of Prof J-M Lehn in Strasbourg. He was a senior research manager

at ICI for 14 years, then research and technical director of MacDermid Autotype for 15 years, during

which time he became a visiting professor at the University of Leeds. He started Steven Abbott TCNF

in 2009 where he works on technical software, coating/printing, nanosystems and formulations. His

technical software includes specialised models for diffusion processes through multi-layer barriers used

in food packaging, personal protective equipment, pharmaceuticals and biomembranes.

Hugh Mallett BSc MSc CGeol SiLC

© Copyright CIRIA 2015. No unauthorised copying or distribution permitted. For use by Triton Systems only.

Hugh is a technical director at BuroHappold Engineering and has a wide variety of professional

experience gained over 35 years on the investigation, assessment and remediation of land affected by

contamination. Hugh’s experience has included the writing and presentation of technical information

for specialists, non-specialist professionals, government ministers and the public.

Project steering group

Following CIRIA’s usual practice, the research project was guided by a project steering group (PSG),

which comprised:

Peter Atchison

PA Geotechnical Ltd

Geoff Card (chair)

GB Card and Partners

Karen Day

Alderburgh

Seamus Lefroy Brooks

LBH Wembley Geotechnical and Environmental (also representing AGS)

Steve McConnell

ACS Lining

Brona McLaverty

Northern Group Systems (Environmental Health)

Richard Menage

Industrial Textiles & Plastics Ltd

Barry Mitcheson

SKM

Andy Shuttleworth

SEL Environmental Ltd

Harry Spillman

ACS Lining

Richard Stevens

Prestige Air Technology Ltd

Karen Thornton

NHBC

Niklas Ullfors

Visqueen

Peter Witherington

RSK

Guidance on the use of plastic membranes as VOC vapour barriers

iii

CIRIA Project manager

Joanne Kwan

Project funders

The work was funded by:

GB Card & Partners

Principal Building Products

SEL Environmental

© Copyright CIRIA 2015. No unauthorised copying or distribution permitted. For use by Triton Systems only.

Visqueen

iv

CIRIA, C748

Contents

Summary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ii

Acknowledgements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . iii

Glossary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . vii

Abbreviations and acronyms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . viii

1Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1.1

1.2

1.3

2

Function of membranes in minimising VOC ingress to buildings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

2.1

2.2

2.3

2.4

2.5

Common misconceptions about membranes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Vapour transport mechanisms through membranes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

2.2.1 Factors that affect permeation rate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

2.2.2 Available data on permeation rates . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2.2.3 Influence of polarity on permeation rate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Permeation tests . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

2.3.1 Permeation test methods . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

2.3.2 ISO 15105-2:2003 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Modelling masss flux . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Multi-layer VOC membranes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

3

Factors that affect the performance of membranes as barriers to VOC migration . . . . . . . . . . . . . . . . . . 13

4

Durability of plastic membranes in relation to contaminant exposure . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

4.1

4.2

© Copyright CIRIA 2015. No unauthorised copying or distribution permitted. For use by Triton Systems only.

Background . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Purpose of this guide . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Risk-based approach . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Potential for chemical degradation of membranes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Chemical resistance tests . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

4.2.1 Test methods . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

5

Risk assessment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

6

Geomembrane types, selection and considerations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

6.1

6.2

6.3

6.4

6.5

7

Types of geomembrane . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Selecting a geomembrane . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

What to consider . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Key performance properties . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

CE marking and third party accreditation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Installation and verification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

References . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Statutes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Further reading . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Boxes

Box 2.1

Example of Hansen Solubility Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Box 5.1

Calculation of permeation through a membrane with different floor slab constructions . . . . . 19

Box 6.1

Thermal stress and settlement stress analysis . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Box 6.2

Estimating required puncture resistance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Guidance on the use of plastic membranes as VOC vapour barriers

v

Figures

Figure 2.1

Illustration of membrane permeation rate to allowable concentrations inside a building . . . . . 3

Figure 2.2

Diffusion of VOCs through the free volume of a membrane . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Figure 2.3

Structure of molecules affects permeation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Figure 2.4

Permeation of vapours through a membrane . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Figure 2.5

Schematic of permeation test cell . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Figure 4.1

Oxidation within 16 weeks immersion, sulphuric acid, % . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Figure 4.2Migration of vapour in reinforcement scrim of aluminium foil membranes. Delamination

within 25 days exposure to diesel vapours at 50ºC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Figure 6.1

Flow chart for choosing an appropriate membrane . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Figure 7.1

Unacceptable installation of a VOC membrane . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

© Copyright CIRIA 2015. No unauthorised copying or distribution permitted. For use by Triton Systems only.

Tables

Table 2.1

Examples of permeation coefficients for VOCs through membranes (vapour phase) . . . . . . . . . 6

Table 2.2

Diffusive mass flux for VOCs through membranes (vapour phase) . . . . . . . . . . . . . . . . . . . . . . . . 7

Table 4.1

Effect of exposure to VOCs on membrane properties . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Table 5.1

Reliance on membrane only . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Table 5.2

Membrane and floor slab . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Table 5.3

Permeation through HDPE membrane if source concentration is taken into account . . . . . . . 20

Table 6.1

Key performance properties . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Table 6.2

Tensile strength required to resist thermally induced forces . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Table 6.3

Tensile strength required to resist settlement induced forces . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Table 7.1

Verification and integrity testing requirements for membranes required to resist VOC ingress . . . 30

vi

CIRIA, C748

Glossary

Challenge chemicalAny chemical used to assess the durability or permeation rate of a membrane when

exposed to that chemical.

The ability of a membrane to remain serviceable when exposed to a hydrocarbon

Hydrocarbon

resistantchallenge chemical, especially VOCs (ie to continue to prevent gas or VOC ingress).

This does not give any indication of the membranes ability to prevent or reduce the

migration of VOC vapours through it. Testing to determine resistance to damage

from VOCs is discussed in Section 4.2.

Mass fluxMass of gas that passes through a membrane per unit area per unit time (Welburn

et al, 2012). This is the property that is required for use in risk assessments.

Note this should be quoted in mg/m2/h. If the manufacturer’s literature does not

quote the permeation rate in mg/m2/h ask them to provide a conversion. It is not

possible to compare the performance of different membranes without using test

data obtained using the same test method and presented in the same units. The

mass flux is calculated from permeation rate tests and is the primary transport

mechanism for VOCs diffusion.

VOCsIn this publication, VOCs are considered to comprise organic compounds that are

volatile under ‘normal’ environmental/atmospheric condition. They may be found

in the ground in the solid, liquid and dissolved phase form as well as in gaseous

phase.

© Copyright CIRIA 2015. No unauthorised copying or distribution permitted. For use by Triton Systems only.

VOC barrierA membrane is considered a barrier to a specific challenge VOC if its steady state

diffusive mass flux, when tested in accordance with ISO 15105-2:2003, is less than

that required to reduce the risk associated with VOC ingress to an acceptable level.

The required level of mass flux will be site specific and depend on a number of

factors such as the concentration gradient across the membrane and the ventilation

provided in the building. For this reason a generic minimum value of mass flux

cannot be specified for VOC barriers. In this guide the term VOC barrier is used,

rather than hydrocarbon barrier (which implies the membrane will be a barrier

to more than just VOCs). The supplier of a VOC barrier should provide all the

necessary test data referred to in this guide to allow risk assessors to determine its

suitability for a given site.

VOC permeation

The rate at which a VOC challenge chemical (liquid or vapour) will pass through

ratea unit thickness of the membrane per unit area per unit time (Welburn et al, 2012).

Units are mg/m2/h. Testing to determine the permeation rate is discussed in Section

2.3. The permeation rate will be dependent on the source concentration and

concentration gradient across the membrane (Scheirs, 2009).

VOC vapours

VOCs in gaseous phase when present in an air space.

Guidance on the use of plastic membranes as VOC vapour barriers

vii

Abbreviations and acronyms

BBA

British Board of Agrément

BTEX

Benzene, toluene, ethyl benzene, xylene

CSPEChlorosulfonate-polyethylene

DPM

Damp proof membrane

EIA

Ethylene Interpolymer Alloy

EPDMEthylene-Propylene-Diene-Monomer

EVOH

Ethylene vinyl alcohol

fPP

Flexible polypropylene

HDPE

High Density Polyethylene

HSP

Hansen Solubility Parameters

LDPE

Low density polyethylene

LLDPE

Linear low density polyethylene

PCETetrachloroethene

SSPR

Steady state permeation rate

© Copyright CIRIA 2015. No unauthorised copying or distribution permitted. For use by Triton Systems only.

TCETrichloroethene

USEPA

US Environmental Protection Agency

VLDPE

Very low density polyethylene

VOC

Volatile organic compounds

viii

CIRIA, C748

1Introduction

1.1BACKGROUND

Buildings are often constructed on sites where volatile organic compounds (VOCs) such as benzene,

toluene, chlorinated solvents, ethers etc are in the ground. The usual remedial solution is to provide a

gas membrane under or over the floor slab, of the same type as used to prevent methane and carbon

dioxide migration into buildings. The membranes are often made from polymeric materials and are

assumed to break the contaminant pathway by preventing vapour transmission. It is well known that

VOCs will migrate through polymeric materials (Welburn et al, 2012, ITRC, 2007, Massey, 2003 and

Scheirs, 2009). In some cases the permeation rate of contaminants through the membrane is so great

that it may not reduce the predicted level of indoor air contamination to acceptable levels, although this

will depend on the concentration of vapour in the ground and the nature of the membrane.

A wide variety of gas membranes are available with very different properties and performance

characteristics. Limited practical guidance currently exists, which enables a robust evaluation of suitable

membranes to enable their specification for use to act as barriers to VOC migration into buildings,

however some examples include Welburn et al (2012) and ITRC (2007).

This guide does not deal with the issues of chemical attack on plastic materials used as buried, in ground

barriers, water pipes, soil reinforcement or similar.

On the basis of current research/evidence (CIEH, 2008) it is very clear that standard damp proof

membrane (DPM) material is not suitable to act as a barrier to VOC migration into buildings in any

circumstances.

© Copyright CIRIA 2015. No unauthorised copying or distribution permitted. For use by Triton Systems only.

This guide provides additional information on VOC permeation through membranes and complements

the information provided by Welburn et al (2012). In preparation of the guide due regard has been given

to the wealth of experience in studying chemical permeation through plastic materials that is available in

the food packaging, protective clothing and other industries.

1.2

PURPOSE OF THIS GUIDE

The purpose of this guide is to provide a summary of the functions of a vapour membrane and the

factors that may affect the performance of the membrane in a protection system for a building on land

contaminated by VOCs. It goes on to explain how to allow for the presence of the membrane in an

indoor inhalation risk assessment. Examples of how to do this are also explained in Welburn et al (2012).

The results of the risk assessment can help determine the necessary performance characteristics of a

membrane for use in a specification.

1.3

RISK-BASED APPROACH

The guide will explain how to take a risk-based approach to the specification of membranes to prevent

VOC migration into new buildings. The approach is consistent with CLR 11 (Environment Agency,

2004), and NHBC guidance (NHBC and Environment Agency, 2008a and b) and Welburn et al (2012).

Wilson (2008) showed that in the UK the Johnson & Ettinger (J&E) model is not suitable for the most

common types of new buildings that do not have basements. It was also suggested that a modular

approach allows the properties of a vapour resistant membrane to be incorporated into the risk

assessment, provided the barrier properties of the membrane can be adequately modelled.

Guidance on the use of plastic membranes as VOC vapour barriers

1

Membranes should not be the only consideration in VOC vapour risk assessment. Assessment

and mitigation of the pathway or link between the source of the VOCs and the building requires

consideration of more than just the membrane. So, the risk model should include the membrane (if

required), floor slab construction and any underfloor ventilation. Effects in the ground that retard

vapour migration should also be considered (eg biodegradation and other processes). With appropriate

modelling it is possible to arrive at a rational, defensible protection system that gives a reasonable balance

between risks and costs (Baker et al, 2009). The use of risk modelling should be fit for purpose, the input

and output parameters should be transparent and their source/use justifiable as part of the process. The

model should be easily understood and be able to be checked by regulators without access to proprietary

software. This will provide regulators and other stakeholders with the necessary confidence in the

data and demonstrate how the final design and specification of the vapour protection system has been

derived and is suitable for use in the context of the land contamination risks on a site-specific basis.

Assessment of the permanent gases such as methane and carbon dioxide is more concerned with acute

health effects or explosions and pressure driven flow. For this reason there is a much greater emphasis

placed on redundancy within the protection system and providing multiple levels of protection.

© Copyright CIRIA 2015. No unauthorised copying or distribution permitted. For use by Triton Systems only.

The major issue with VOCs is normally long-term chronic health risks and there is less need for the

same levels of redundancy used for permanent gases, although a precautionary approach should still

be adopted. The level of redundancy in the protection system will depend on how effective in ground

processes (such as biodegradation) and the floor slab construction will be in retarding vapour migration

(Welburn et al, 2012). The potential for hazardous daughter/by-products from biodegradation processes

should also be considered, eg vinyl chloride from chlorinated solvent breakdown.

2

CIRIA, C748

2 Function of membranes in

minimising VOC ingress to

buildings

2.1

COMMON MISCONCEPTIONS ABOUT MEMBRANES

At present there are some common misconceptions about vapour transmission through membranes that

are marketed as being ‘hydrocarbon resistant’. This means that the protection provided could possibly be

much less than expected. So, first ask what is meant by hydrocarbon resistant? Does this refer to vapour

permeation rate through the membrane or to resistance to degradation when exposed to hydrocarbons

and particularly VOCs? The two properties are different (see Glossary).

In contrast to how well a membrane withstands chemical attack, permeation measures the rate at which

the challenge chemical moves through a membrane at molecular level. The polymer(s) forming the

membrane will permeate contaminants depending on how similar the molecular structure is to the

challenge contaminant.

© Copyright CIRIA 2015. No unauthorised copying or distribution permitted. For use by Triton Systems only.

There is a common misconception that High Density Polyethylene (HDPE) completely prevents

VOC migration through it. VOCs and methane will permeate readily through homogeneous HDPE

membranes mainly because the two are of the same species, ie both HDPE and many VOCs are

hydrocarbons. However, in contrast to methane and carbon dioxide many VOCs can migrate through

it at a rate that is quite high in comparison to the allowable concentrations of those vapours inside

buildings. This is illustrated in Figure 2.1. Note the figure is illustrative only and the actual mass flux

through the membrane will depend on the concentration gradient across the membrane.

Figure 2.1

Illustration of membrane permeation rate to allowable concentrations inside a building

Guidance on the use of plastic membranes as VOC vapour barriers

3

So, membranes used to reduce VOC migration into buildings will require very low mass flux through

them in comparison with the internal allowable concentration of the VOC being considered. Reducing

the permeation rate for VOCs by increasing the thickness is not particularly effective or practical in most

cases. To halve the permeation rate, the thickness would need to be doubled.

Extensive experimental evidence (August and Tatzky, 1984) shows that benzene, toluene, ethyl benzene

and xylenes (BTEX) can permeate rapidly through HDPE if it is exposed to high concentrations of the

chemicals (reaching equilibrium concentrations in 10 to 20 days). In some cases they may not be that

effective as barriers to these molecules. In light of this it should not be assumed that a membrane alone

will block vapour migration of all VOC contaminants into a building and a site specific assessment of any

membrane should be completed (see Chapter 6).

2.2

VAPOUR TRANSPORT MECHANISMS THROUGH

MEMBRANES

2.2.1 Factors that affect permeation rate

© Copyright CIRIA 2015. No unauthorised copying or distribution permitted. For use by Triton Systems only.

Vapour permeability will vary greatly according to membrane material and the nature of the vapour.

The correct specification for a membrane to act as a barrier to VOC ingress to buildings is critical.

However the quality of the membrane is only one factor. If any membrane is poorly installed the main

way in which vapours will pass through it will be via holes/punctures, poor joints and seals and/or other

defects, rather than through the material itself. If the quality/specification of the membrane and integrity

of the installation is adequate to minimise such defects the dominant mode of vapour transport will be via

molecular diffusion through the membrane. This is in contrast to transport mechanisms for methane and

carbon dioxide in soils, where the main driving force is often (but not always) the pressure head.

The key fact about the concentration gradient is that it depends both on the amount/concentration of

contaminant in the soil or groundwater and the solubility of the contaminant in the polymer surface

exposed to the contaminant. If it is insoluble (eg water exposed to the surface of polyethylene) then

despite a high concentration of water in the soil and despite the fact that water is a very small molecule,

little water will permeate because it is

insoluble. If it is soluble (eg benzene

exposed to the surface of polyethylene)

then the concentration gradient between

one side of the membrane and the other

can be large, so permeation will be

large, and as a result the membrane will

be ineffective as a vapour barrier.

Molecular diffusion is driven by a

concentration gradient with molecules

moving from zones of higher to lower

concentration. Any given molecule

may move through free spaces within

the membrane. The speed at which it

moves depends on the amount of free

volume in the membrane structure.

Typically membranes made of rubbers

have large amounts of free volume and

small molecules from the contaminant

source, eg benzene, will readily move to

fill this free space, ie an area of lower

concentration (Figure 2.2).

Figure 2.2Diffusion of VOCs through the free volume of a membrane

4

CIRIA, C748

The regular, symmetrical structure of HDPE means it is highly crystalline with about 20 per cent that

is amorphous. The free volume is low but benzene permeation will take place through the free volume

of the amorphous areas. If one of the hydrogen atoms is substituted with a methyl group (flexible

polypropylene) or chlorine (PVC) the crystallinity is reduced and the free volume increases. Smaller

molecules (eg benzene) will move faster than larger molecules (eg paraffin). In summary, permeation

depends on:

the concentration gradient

the nature of the membrane (free volume)

thickness of the membrane

the solubility of the contaminant in the polymer (which depends on molecular structure and

polarity, see Section 2.4)

the shape/size of the molecule and whether it is streamlined (Figure 2.3).

Bulky molecule,

eg o-xylene

Streamlined molecule,

eg p-xylene

Figure 2.3

Structure of molecules affects permeation (after Scheirs, 2009)

© Copyright CIRIA 2015. No unauthorised copying or distribution permitted. For use by Triton Systems only.

The permeation of vapours through a membrane is summarised in Figure 2.4.

Figure 2.4

Permeation of vapours through a membrane

The permeation rate will also vary depending on whether the membrane is saturated with the challenge

chemical (Wilson, 2008b). Over time VOCs can partition into the membrane until it is saturated (this will

depend on the concentration of the VOC in the ground). This will cause the membrane to swell and the

permeation rate will increase once the membrane is saturated.

Guidance on the use of plastic membranes as VOC vapour barriers

5

When a membrane is exposed to a VOC the molecules first of all diffuse into the membrane. Eventually

they will reach the other side of the membrane and breakthrough occurs. Before the breakthrough

point there is essentially no permeation as the chemical is migrating into the membrane material but

has not yet passed completely through it. The permeation rate is constant at zero. After breakthrough the

permeation builds up to its steady state (ie constant equilibrium) value as the membrane becomes saturated

with the VOC. The steady state value may be achieved within days in some cases (Chin et al, 2013).

2.2.2 Available data on permeation rates

There is limited, readily available, peer reviewed data on the permeation rates through membranes

used in building construction. One set of data for two particular VOCs (benzene and toluene) has been

published in a series of papers by Islam and Rowe (2001), Sangam and Rowe (2009), McWatters and

Rowe (2009), and McWatters and Rowe (2010). This is summarised in Table 2.1.

Table 2.1

Material

Chemical

Permeation coefficient (m2/s)

Nylon VBP15 coextruded

Benzene

0.02 × 10 -10

LLDPE:polyamide:LLDPE

Toluene

0.02 × 10 -10 to 0.03 × 10 -10

EVOH coextruded

Benzene

0.009 × 10 -12

LLDPE:EVOH:LLDPE

Toluene

0.011 × 10 -12 (1)

Benzene

0.1 × 10 -10

Toluene

0.2 × 10 -10

Benzene

0.2 × 10 -10

Toluene

0.4 × 10 -10

Benzene

0.2 × 10 -10

Toluene

0.8 × 10 -10

Benzene

2.29 × 10 -12

Toluene

7.74 × 10 -12

Benzene

2.07 × 10 -12 to 2.83 × 10 -12

Toluene

4.90 × 10 -12 to 7.22 × 10 -12

LLDPE

LLDPE

PVC

HDPE

HDPE

© Copyright CIRIA 2015. No unauthorised copying or distribution permitted. For use by Triton Systems only.

Examples of permeation coefficients for VOCs through membranes (vapour phase)

Thickness of

Source

material (mm)

0.38

McWatters and Rowe (2010)

0.53

McWatters and Rowe (2010)

0.53

McWatters and Rowe (2010)

0.76

McWatters and Rowe (2009)

0.76

McWatters and Rowe (2009)

2.00

Sangam and Rowe (2001)

1.50

Islam and Rowe (2001)

Note

1The result quoted for LLDPE:EVOH:LLDPE is misleading. Other tests have not been able to detect anything passing through this type of

membrane. The data point is likely to be simply the amount of benzene absorbed by the first layer of LLDPE. It is better to consider this

value as <0.009 × 10 -12.

The values in the table are permeation coefficients, not permeation rates. If the diffusive mass flux is

not quoted for a material in mg/m2/hr for a standard concentration (eg pure liquid) it is difficult to make

any reasonable comparison of membranes in a simple risk assessment. However an estimate of the likely

diffusive mass flux of a chemical through a membrane can be estimated using the permeation rates in

Table 2.1 using the following equation (Fick’s Law of Diffusion):

Diffusive mass flux of chemical [ML-2T-1] = Pg (dCf /dz)

Where:

Pg =Permeation coefficient [L2T-1] that allows for partitioning and diffusion processes at each

side and within the membrane, from Table 2.1. Values for other VOCs have not been found

in a literature search and would have to be determined from specific testing.

6

dCf=

Difference in concentration of chemical from one side of membrane to other (Figure 2.4).

dz =

thickness of membrane (Figure 2.4).

CIRIA, C748

Care should be taken when using the permeation coefficients as they only relate to the thickness of

material and concentration of the particular chemical used in the tests.

Data on diffusive mass flux through membranes may be presented in other forms from that in Table

1.1 and commonly, results from laboratory tests quote the values in terms of a mass per unit area per

unit time (eg mg/m2/h). Values for the permeation of xylene and toluene through different thicknesses

of HDPE membrane are provided in Table 2.2. The table also shows the variation that occurs due to

changes in the concentration of the challenge chemical on the dirty side of the membrane.

Table 2.2

Material

Diffusive mass flux for VOCs through membranes (vapour phase)

Diffusive mass

flux (mg/m2/h)

Thickness of

material (mm)

916

0.8

500

2.6

750

0.75

Xylene (10 mg/l)

0.71

0.76

Xylene (50 mg/l)

3.21

0.76

Xylene (100 mg/l)

13.29

0.76

Xylene (100 mg/l)

1.79

1.52

Xylene (100 mg/l)

0.58

2.54

Toluene (10 mg/l)

0.79

0.76

Toluene (50 mg/l)

4.42

0.76

Toluene (100 mg/l)

14.58

0.76

Toluene (100 mg/l)

2.92

1.52

Toluene (100 mg/l)

1.00

2.54

Chemical

HDPE

HDPE

Xylene

LDPE

HDPE

© Copyright CIRIA 2015. No unauthorised copying or distribution permitted. For use by Triton Systems only.

HDPE

Source

Schiers (2009)

Thomas and Koerner (1996)

Thomas and Koerner (1996)

Note

The tests are assumed to have used m,p and o xylenes as the isomer is not stated in the source references.

In practice, brownfield sites are contaminated by a wide spectrum of pollutants which vary from site to

site. It is therefore important that the barrier membrane can demonstrate adequate barrier performance

against each pollutant that is of concern on a particular site (a chemical may be present, but not at levels

that constitute a risk to the occupiers).

2.2.3 Influence of polarity on permeation rate

The molecular structure and polarity of the membrane is one important factor in the rate of permeation

of the challenge chemical. Polarity is an indication of a balanced or unbalanced molecular electric field

and is determined by polar and hydrogen bonding.

A standard chemical rule is that ‘like is soluble in like’. So if the membrane material and contaminant

are either both polar or both non-polar the solubility will be high and the permeation rate will be high.

If the membrane material is polar and the contaminant is non-polar (or vice versa) the contaminant will

not be soluble and permeation will be low. Water is a common example of a polar material and grease, a

non-polar material. Grease does not readily dissolve in water (although it can form an emulsion).

Guidance on the use of plastic membranes as VOC vapour barriers

7

To be an effective barrier, a membrane needs to demonstrate a sufficiently low permeability for each

contaminant of concern on a particular site, be it a VOC or other chemical. As a membrane’s barrier

performance is defined by its composition it may be suitable as a barrier for one type of challenge

chemical but not against other types. For example, polyamide is polar and so provides a good barrier

against non-polar chemicals, especially non-polar VOCs such as BTEX. HDPE is non-polar and does not

provide a good barrier against non-polar chemicals, in particular some VOCs at high concentrations.

2.3

PERMEATION TESTS

As a result of the difficulty in finding data for this research project and the multitude of units that are

used, it is recommended that manufacturers of membranes designed to be used to limit VOC vapours

into buildings should provide data on the permeation of vapour from the following range of chemicals as

a minimum. The results of tests to determine permeation rates of contaminants for a specific membrane

are essential to allow effective risk assessment. Membrane manufacturer’s literature should be required

to verify the permeation rate relevant to the contaminant of concern. The tests should be undertaken

at a range of contaminant concentrations and on samples including a typical joint (welded or taped). A

commercial laboratory has indicated that it is feasible to test the jointed materials.

The testing should provide permeation rates for the following chemicals:

benzene

toluene

ethyl benzene

m, p and o xylenes

hexane

vinyl chloride

tetrachloroethene (PCE)

trichloroethene (TCE)

naphthalene (solid at room temperature but will still produce vapour phase contamination due

to partitioning). Test methods have been developed to test naphthalene vapour migration across

membranes although they are not standard tests (Nerin et al, 2007).

© Copyright CIRIA 2015. No unauthorised copying or distribution permitted. For use by Triton Systems only.

Recommended test methods for determining the permeation rate are discussed in the following subsections.

Specific sites may require testing of the membrane for other chemicals depending on the nature of the

contamination in the ground. There may be a number of VOCs that will each require separate risk

assessments. It is also important to be mindful of volatile hazardous daughter/by-products resulting

from natural attenuation/biodegradation of the main contaminants. Synergistic effects of different

contaminants also need to be considered.

Both in the UK and elsewhere, regulators and designers are increasingly being supplied with evidence

from suppliers to allow them to carry out risk assessment modelling with regard to migration of VOC

contaminants of concern through a membrane. This is providing greater reassurance to all that the

membrane is suitable for use as a barrier to VOC migration into buildings.

2.3.1 Permeation test methods

Quantifying the effectiveness of a membrane is a key component in deciding upon a membranes

suitability for a given application or type of contamination. To do this permeation data is required that

can be incorporated into risk assessments to demonstrate the effect of proposed mitigation measures.

Originally, gravimetric test methods were developed to assess the rate of permeation. Such tests are

generally rudimentary and involve sealing a membrane over a jar of the challenge chemical and

8

CIRIA, C748

measuring the weight loss over time. Gravimetric permeation test methods include ASTM E96/E96M-05,

ASTM D5886-95 and BS EN ISO 6179:2010.

The main limitation on these tests is a lack of knowledge about the vapour concentration of the chemical

on either side of the membrane. However they usually have a very high concentration of vapour on the

chemical side of the test so are worst case for most, if not all contaminated sites. They can be carried

out quickly and easily to give some indication of likely permeation rates. The results are useful for

comparing relative transmission rates of a chemical through different membranes.

There are some limitations to the BS EN ISO 6179 test. It is only applicable to materials in sheet form

and to coated fabrics having a thickness between 0.2 mm and 3.0 mm. It is restricted to measuring

transmission rates (or mass flux) greater than 0.1 g/m2/h (100 mg/m2/h), which extrapolates to a

minimum mass flux of 876 g/m2/yr. This is too high to be useful for many VOC vapour risk assessments.

2.3.2 ISO 15105-2:2003

Over time modern permeation test methods have been developed that are highly accurate and

measure steady state permeation rates using mass spectrometry. One such test is described by ISO

15105-2:2003. This specifies a method for determining the gas transmission rate of plastic materials

in the form of film, sheeting, laminate, co-extruded material or flexible plastic-coated material. The

resistance of a membrane to permeation by liquid or gaseous contaminant chemicals is defined by the

breakthrough time and steady state permeation rate (SSPR) of the chemical through the barrier at a

given concentration of the chemical.

From a regulatory position transparency, clarity and accuracy in the testing are key. It is also essential

that there is consistency in approach to ensure comparability and there should be confidence from

all parties that the outcome of the process is accurate and protective. It is recommended that the ISO

15105-2 test method is adopted as the industry standard for providing data on permeation rates through

membranes for use in contaminated land risk assessment.

© Copyright CIRIA 2015. No unauthorised copying or distribution permitted. For use by Triton Systems only.

The permeation testing introduces a test gas or vapour to one side of the membrane. On the other

side a ‘sweep’ gas collects gas permeating through the membrane and takes it to a detector. The sweep

gas is normally an inert gas such as nitrogen or helium. Detection can be undertaken using a number

of instruments including mass spectrometers. The pressure on each side of the membrane is equal. A

schematic of the permeation test is shown in Figure 2.5.

Figure 2.5

Schematic of permeation test cell

The test system records the volume of any permeate as a function of time after its initial contact with

the membrane. The gas transmission rate is reported as mol/(m2s Pa) by laboratories and the results

will require conversion to units that are easily used in risk assessment at standard conditions under

a pressure of one atmosphere (mg/m2/h). This should be done by the manufacturer to provide values

for their literature. Minimum detection rates will depend on the test apparatus set up and detection

equipment used. However they are typically much lower than those achievable using gravimetric

methods. It is also useful to determine the diffusion or permeation coefficient for a membrane.

Guidance on the use of plastic membranes as VOC vapour barriers

9

Even so, it may be difficult to measure the permeation of materials with extremely good barrier

performance. The sample may take an extremely long time to reach equilibrium saturation and steady

state permeation, resulting in a large cost. Tests that run for a long time also increase the risk of

permeation to or from the external environment. Even if steady state permeation is achieved, the flux

may be so low that detectors may not be able to measure it accurately. This is a commercial decision for

manufacturers. The laboratory test certificate should state the outcome of the tests only and it is the

responsibility of a risk assessor or protection designer to determine if a given set of results are acceptable

on a particular site.

Further information on the available test methods for measuring permeation and diffusion in polymers

is provided by Duncan et al (2005).

The test report should include the following information that is required by risk assessors:

the mass flux in mg/m2/h

the thickness of the test sample

the concentration of the challenge chemical used to complete the test (on the dirty side)

results of the evaluation process undertaken by the remediation designers to assess the impact of

providing different membranes in the floor slab construction.

2.4

MODELLING MASS FLUX

Physical testing of permeation rates through a particular membrane is usually only available for a limited

number of challenge chemicals (see previous section). This may be acceptable because the risk assessment

process for land contamination usually focuses on a few limited marker compounds. For example, using

the TPH CWG Criteria Working Group carbon bands the properties of a marker chemical are used to

define the risk assessment properties for each band (eg C6 to C8).

© Copyright CIRIA 2015. No unauthorised copying or distribution permitted. For use by Triton Systems only.

If the mass flux for a wider range of chemicals is required then the values can be estimated using

modelling, or specific testing can be undertaken (although costs and timescales may not fit in with

construction programmes). Modelling is also useful for comparing the difference in performance

between materials.

One convenient approach to modelling a large variety of chemicals interacting with a barrier is that

of Hansen Solubility Parameters (HSP) (Hansen, 1999 and 2009). This has been used to model the

permeation of chemicals through a membrane developed to provide protection to buildings against

VOC vapours. Each polymer and chemical has a set of the three parameters that make up HSP: δD, δP,

δH, which respectively capture the dispersion, polar and hydrogen-bonding chemistry. As ‘like dissolves

like’ so chemicals with HSP similar to those of a polymer will be ‘like’ and therefore soluble. A simple

calculation of ‘HSP distance’ (based on the sum of the square of the differences between the three

parameters) makes it possible to estimate solubility. For membranes, even more important than solubility

are partition coefficients. These are readily estimated from the relative HSP distances. An example of

using HSP to estimate the likelihood of solubility is provided in Box 2.1.

10

CIRIA, C748

Box 2.1

Example of Hansen Solubility Parameters

The three Hansen Solubility Parameters (HSPs) are co-ordinates for a point in three dimensions. Molecules that are close

together in this three dimensional space are more likely to dissolve into each other. The procedure to determine if the

parameters of the solvent and the membrane polymer are within range to be soluble is as follows (Abbott, 2008):

1

A value called interaction radius (R0) is determined for the membrane being dissolved using experimental test data

on a limited set of solvents. This value determines the radius of the sphere in Hansen space and the x, y and z

co-ordinates of its centre are the three Hansen parameters. Once this and the other HSPs are known for a set of

chemicals the solubility of the membrane in other chemicals can be determined.

2

Calculate the interaction radius (Ra) between Hansen parameters in Hansen space using the following formula:

(Ra)2 = 4(δD2 –δD1)2 + (δP2 – δP1)2 + (δH2 – δH1)2

δD = energy density from dispersion forces between molecules

δP = energy density from dipolar intermolecular force between molecules

δH = energy density from hydrogen bonds between molecules

D2, D1 etc refer to the parameters for the solvent and membrane respectively.

For benzene

δD = 18.4 MPa0.5, δP = 0.0 MPa0.5, δH = 2.0 MPa0.5 from (Hansen, 1999)

For a certain PVC polymer (PVC 4 HR)

δD = 24.4 MPa0.5, δP = 4.9 MPa0.5, δH = 9.9 MPa0.5 and R0 = 22.7 MPa0.5 (Hansen, 2009).

So for PVC/benzene, Ra = 15.18

3

Calculate the relative energy difference, RED = Ra/Ro = 15.18/22.7 = 0.67.

4

Compare the values to the following list:

RED <1 means the molecules are alike and will dissolve/absorb.

RED = 1 means the molecules will partially dissolve/absorb.

RED >1 means the molecules will not dissolve/absorb.

In the case of PVC and benzene RED is <1 and the initial indication is that benzene will dissolve or adsorb into the PVC

and will pass through easily.

Similar calculations for LDPE (δD = 16.5 MPa0.5, δP = 4.5 MPa0.5, δH = 0.5 MPa0.5 and R0 = 6.0 MPa0.5) gives an RED of

1.0, which again indicates that benzene may pass through it but not as easily as PVC.

Other modelling approaches that are being developed to assess diffusion of chemicals through materials are described

by Duncan et al (2005). These include methods that consider the concentration gradient across a membrane.

© Copyright CIRIA 2015. No unauthorised copying or distribution permitted. For use by Triton Systems only.

2.5

MULTI-LAYER VOC MEMBRANES

In general a membrane made from a single material cannot resist all chemicals (hence packing films

in the food industry are multi-layer membranes). An HDPE membrane is not necessarily a suitable

defence against BTEX permeation and it cannot be assumed to break the migration pathway (it will

depend heavily on the vapour concentration of the contaminant in the ground below the floor slab). For

each of the common membrane materials such as butyl, chlorosulfonate-polyethylene (CSPE), ethylenepropylene-diene-monomer (EPDM), flexible polypropylene (fPP) and ethylene interpolymer alloy (EIA)

there are similar circumstances where a common pollutant chemical (VOC) can easily permeate or

compromise the physical properties of the membrane (strength, permeation rates etc) if it is present at a

sufficiently high concentration.

Examples of multi-layer membranes used to prevent ground gas or vapour ingress into buildings include:

LLDPE, LDPE or HDPE with an aluminium foil core

LDPE:EVOH:LDPE

HDPE:EVOH:HDPE

HDPE:polyamide:EVOH:polyamide:HDPE (or variations on this layering)

HDPE:VLDPE (although these materials are very similar in terms of VOC permeation)

asphalt latex:HDPE.

Guidance on the use of plastic membranes as VOC vapour barriers

11

A simple example of how multi-layer barriers work in food packaging is given as follows. The same

principles can be applied to membranes that are required to prevent VOC vapour ingress into buildings.

LDPE is an excellent moisture barrier and a poor oxygen barrier, while EVOH co-polymer is an excellent

oxygen barrier but a poor moisture barrier. So a typical packaging film will be an LDPE:EVOH:LDPE

sandwich. The LDPE provides not only the moisture barrier but also protection for the rather delicate

EVOH. The EVOH provides the oxygen barrier properties only as long as it remains protected from

moisture and handling damage by the LDPE. The two layers of LDPE provide insurance against

any deterioration of general mechanical properties from one side. For example, if the inner LDPE is

weakened by a soluble contaminant, that contaminant will tend to be blocked by the EVOH and so will

not have a chance to weaken the other LDPE layer.

An HDPE:EVOH:HDPE membrane will provide a barrier against migration of benzene. This is because

benzene has exceptionally low solubility in EVOH. The same barrier will also prevent methanol

migration because although the EVOH readily transmits methanol (the HSP distance is low), the

exceptionally low solubility of methanol in HDPE provides a barrier. The barrier properties are less

effective for intermediate pollutants, which are partially soluble in both HDPE and EVOH. For example,

for methyl t-butyl ether the reduction in permeation rates is only 5 orders of magnitude, because the

ether is less insoluble in the EVOH.

© Copyright CIRIA 2015. No unauthorised copying or distribution permitted. For use by Triton Systems only.

For extra robustness further polymer layers may be added with a different solubility profile from HDPE

and EVOH. This makes the chances of adequate solubility in each layer becoming smaller and the

barrier properties remain acceptable over a wide range of pollutants.

12

CIRIA, C748

3 Factors that affect the

performance of membranes as

barriers to VOC migration

Membranes in buildings could potentially be exposed to a wide variety of VOC compounds in

the ground. The exact cocktail of chemicals will vary from site to site. The main requirements for

membranes used as barriers to VOC permeation are:

The permeation rate of the challenge chemicals through the membrane should be sufficiently low. This

should take account of the vapour concentration below the membrane if data is available to do this.

The mechanical properties (strength, tear resistance etc) of the membrane should not be adversely

affected by the challenge chemicals such that its performance as a barrier is compromised.

The membrane should be able to withstand the physical stresses placed on it both in the permanent

state, but more importantly during construction.

The membrane should not suffer from biological or other forms of degradation (oxidisation, stress

cracking etc).

© Copyright CIRIA 2015. No unauthorised copying or distribution permitted. For use by Triton Systems only.

Because of the very low permeation rates that are usually required to minimise the risks associated with

VOC vapours it is extremely important that the membrane is installed correctly and is not damaged

afterwards. So, where VOC membranes are required, integrity testing should be carried out unless

the designer specifies in the verification plan that it is not required and justifies this decision. An

example where integrity testing may not be required would be where the level of risk is very low and the

membrane is being installed as a precaution as part of a multi-level protection system. This is discussed

in more detail in Chapter 6.

Guidance on the use of plastic membranes as VOC vapour barriers

13

4 Durability of plastic membranes

in relation to contaminant

exposure

4.1

POTENTIAL FOR CHEMICAL DEGRADATION OF

MEMBRANES

Membranes used in gas or vapour protection systems may be subject to various forces (tearing, shearing,

tensile forces) or can potentially be exposed to aggressive chemicals (eg benzene, toluene or other

vapours). In extreme cases this can result in the loss of integrity or serviceability and undermine the

effectiveness of the protection system.

The potential for chemical attack on a membrane will depend on:

the presence of a pathway for the challenge chemical to reach the membrane

the availability of the challenge chemical, ie concentration and the rate at which it migrates towards

the membrane

degree of contact between the challenge chemical and the membrane material

© Copyright CIRIA 2015. No unauthorised copying or distribution permitted. For use by Triton Systems only.

the sensitivity of the membrane to the challenge chemical, in particular, the polarity of the

contaminant and the susceptibility to partitioning of the membrane material by the challenge

chemical (ie how easily it is absorbed).

In building applications the membrane should not be exposed directly to the source of the

contamination and should only be exposed to vapours that have migrated through the ground. The

presence of water increases partitioning of vapours into polymers, so in theory the concentration at

the membrane interface could be higher than might be expected. This could be a concern where the

membrane is in direct contact with contaminated soils, but is less of a concern where the membrane is

separated from the source of contamination. Membranes in building construction will usually be located

either above the slab or on top of the sub-base both of which will have relatively low moisture contents. So

the vapour concentration at the membrane will normally be much lower than the source concentration in

the ground.

Different membrane materials may be adversely affected by different contaminants. For example,

HDPE readily loses greater than 50 per cent of its structural strength when exposed to 100 per cent

concentrations of challenge contaminants such as BTEX. HDPE will absorb halogenated and/or

aromatic hydrocarbons (including many fuels and oils) at greater than 50 per cent concentration (Rowad

International, 2013). For one reinforced membrane the chemical compatibility chart indicates minor to

moderate effects for benzene at one per cent and 25 per cent concentration but severe effects at 100 per

cent concentration (Layfield, 2013) although the membrane material is not stated. Another membrane

showed only minor effects when exposed to one per cent toluene but minor to moderate effects at 25 per

cent concentration.

In a building application HDPE may not be exposed to high concentrations of challenge chemicals and

may not be subject to any great tensile loads (eg when laid on top of a slab). In this instance the risk of

damage due to exposure to the challenge chemicals will be a lot lower than indicated by exposure tests

at 100 per cent concentration. The potential for adverse effects should be assessed on a site specific basis,

preferably using exposure data at concentrations that reflect site conditions.

14

CIRIA, C748

The main properties that exposure to chemicals can affect are listed in Table 4.1.

Table 4.1

Effect of exposure to VOCs on membrane properties

Property

Possible effects

Thickness

The primary effect of exposure of polymeric membranes to VOCs is swelling. The VOCs are absorbed

by the membrane, which results in weight gain. Swelling can cause waves to form across a membrane,

which can exert peel forces on welds. This is not likely to be a significant issue in small areas of

membrane that are restrained by the floor construction. Potentially the most significant effect is that

swelling can increase the permeation of chemicals through the membrane (Duncan et al, 2005).

Weight

The absorption of VOCs causes an increase in weight of the membrane. In most applications the

increase in weight is not a significant issue in itself. In chemical immersion tests a mass gain of 10 per

cent or more is taken to indicate that the membrane will not be resistant to exposure to the chemical

solution (Scheirs, 2009).

The absorption of VOCs causes softening of the material with a resultant loss of tensile strength. Where

the membrane is fully supported by a suspended floor slab this is not likely to be a significant issue. Where

a membrane is below a floor slab and is required to resist tensile forces caused by settlement it needs to

be considered. In chemical immersion tests if the elongation at break decreases by less than 20 per cent

Tensile strength

(in relative terms) this indicates that there is no significant effect on the membrane. The effects of swelling

and reduction of strength and stiffness caused by VOCs are not permanent and do not generally cause

permanent degradation of membranes. The effects also only occur up to a certain point and after the

VOCs volatilise out of the membrane the original properties are recovered (Scheirs, 2009).

Stiffness

As for tensile strength softening will reduce the stiffness of the membrane.

Antioxidant or

stabiliser levels

Absorption of VOCs can cause a loss of antioxidants or stabilisers added to the membrane material. This

can result in oxidation or stress cracking of the membrane occurring in service.

4.2

CHEMICAL RESISTANCE TESTS

© Copyright CIRIA 2015. No unauthorised copying or distribution permitted. For use by Triton Systems only.

Chemical resistance is different from chemical permeation and different tests are required to those

discussed in Section 2.3. Membrane providers may claim that their membranes ‘meet chemical resistance

standards’ when in fact the membrane has a high level of permeation. The fact that a membrane

complies with a standard with regard to chemical resistance does not necessarily mean that it is fit for

purpose in a particular situation as it may have a high permeation rate to the contaminant and allow

migration through the barrier. It is important to make this distinction between chemical resistance and

barrier performance since chemical resistance tests do not provide any permeation data. A membrane’s

chemical resistance (like its barrier performance) is defined by its composition.

4.2.1 Test methods

ASTM D5322-98 (2009) is a widely recognised test method for chemical resistance and it is incorporated

within the Method 9090A (EPA, 1992) and ASTM D5747/D5747M-08 (2013)e1. The European test

method procedures described in BS EN 14414:2004 and BS EN 14415:2004 are virtually identical to

ASTM D5322-98, the main difference being that the European Standards define a fixed test period of

56 days, while the ASTM Standard allows the manufacturer to determine the duration of the test period.

The test procedure involves immersing a sample of membrane in the challenge chemical at an elevated

temperature of 50°C for the test period after which it is inspected. Thickness, weight, tensile strength

and elongation are then compared with a control sample and providing variations are within 25 per cent

of the control sample test results, the membrane is considered chemical resistant.

An important limitation of these standards is the choice of challenge chemicals that are actually tested.

BS EN 14414 tests for the following:

Method A – acid: 10 per cent solution H2SO4

Method B – alkali: saturated Ca(OH)2

Guidance on the use of plastic membranes as VOC vapour barriers

15

Method C – diesel, paraffin and lubricating oil mixture

Method D – synthetic leachate comprising a mixture of 14 acids, chlorides, sulphates and a

phosphate.

BS EN 14415 tests for the following:

Method A – hot de-ionised water

Method B – alkalis test

Method C – organic solvents (methanol, isopropanol, and glycol).

BS EN 14414 test Method C is the relevant immersion test for hydrocarbons. This single immersion test

comprises a challenge solution cocktail of 35 per cent diesel fuel, 35 per cent paraffin and 30 per cent

lubricating oil. Those familiar with basic principles of chemical solvency will realise that this test for

‘hydrocarbons’ is highly optimistic in terms of VOCs. The test materials are large molecules that make

naturally poor solvents. Although VOCs such as BTEX are ‘hydrocarbons’ they are generally much

more aggressive solvents than this test mix. So extended testing using specific chemical compounds is

preferred. In light of this it is recommended that any membrane exposed to VOCs has additional tests

undertaken to confirm its durability when exposed to the following basic suite:

benzene

toluene

ethyl benzene

m, p xylene

xylene

hexane

vinyl chloride

tetrachloroethene

trichloroethene

naphthalene.

© Copyright CIRIA 2015. No unauthorised copying or distribution permitted. For use by Triton Systems only.

Manufacturers should provide this test information and designers and regulators should ask for it before

agreeing to the use of any membrane that is exposed to significant levels of the chemicals (eg in direct

contact with soil or groundwater contaminated with challenge chemicals).

Tests using other chemicals may also be required depending on the specific contaminants and the

exposure conditions of a membrane on a site. It would also be beneficial if manufacturers carried out

durability tests using low concentration aqueous solutions of chemicals to obtain a better understanding

of the effects of exposure to low concentrations of chemicals (which is likely to be the dominant case

where membranes are used in building construction).

HDPE passes the EN 14414 Method C chemical resistance tests, which is an accelerated life test

comprising immersion at 50°C for 56 days in the mixture of diesel, paraffin and lubricating oil described

previously. However if the membrane is exposed to contaminants more aggressive than diesel a

reduction in structural strength could occur (eg if exposed to BTEX in high concentrations). This may

be an issue, for example, where a membrane is laid below a slab and there is movement in the soil. This

will be less of a problem where membranes are placed over the top of floor slabs.

Aluminium laminate membranes are commonly used to prevent gas and vapour ingress to buildings.

There is no disputing the robustness of an intact and continuous aluminium barrier against permeation

of almost any common organic pollutant – aluminium simply does not allow any permeation. However,

the relatively thin layer is susceptible to corrosion as a result of oxidation if it is exposed due to damage

to the protective layers on either side. This can occur in either acid (Figure 4.1) or in alkaline conditions

and reduces its barrier properties to a low level. Also the aluminium layer itself is so delicate that it has to

be protected by reinforcement scrims and can tear if there is any extension, for example, due to ground

16

CIRIA, C748

movements or shear forces during installation. So, a reinforcement scrim is necessary to reduce the risk

of tearing.

Figure 4.1Oxidation within 16 weeks immersion,

sulphuric acid, % (EN14414 Method A)

Figure 4.2Migration of vapour in reinforcement scrim of

aluminium foil membranes. Delamination within

25 days exposure to diesel vapours at 50ºC

© Copyright CIRIA 2015. No unauthorised copying or distribution permitted. For use by Triton Systems only.

Permeation tests on aluminium foil laminates demonstrated that migration can also occur along the

outer membrane and this cannot be sealed at joints. This can be a significant pathway where there

are multiple joints (eg in housing where the membrane is joined to a damp-proof course around the

perimeter of a room). The carrier polymers, particularly the lower density polymers for the laminate (eg

LDPE) can themselves be more prone to be compromised by BTEX at sufficiently high concentrations

allowing the aluminium to be torn or punctured. The thinner the outer membrane the greater risk there

is of this happening. The membranes can also delaminate when the chemical condenses between the

polymer layer and the foil layer, reducing the structural integrity (Figure 4.2 shows delamination and

condensation depicted by the bubbling). Therefore such membranes are less suitable for sites with highly

elevated concentrations of VOC vapours or where significant movement of the membrane is expected,

for example, due to settlement.

Guidance on the use of plastic membranes as VOC vapour barriers

17

5 Risk assessment

Risk assessment for VOC vapour inhalation in buildings should be undertaken to determine if there

is a potentially unacceptable risk to the occupants of a building. The risk assessment should be site

specific using realistic parameters for the building and ground (for example, do not assume there is

a crack around the perimeter of a floor slab if the proposed construction means that one will not be

present). The J&E model assumes a perimeter crack but it can be modified to remove it. If the level of

risk is deemed to be unacceptable then the effect of introducing ventilation below the floor slab and

a membrane can be modelled in the risk assessment to determine the appropriate level of protection.

The properties of any membrane can be included in the model to help determine the necessary level of

performance and allow the specification of a suitable membrane. A method of modelling vapour ingress

that can be adapted to allow for the properties of the membrane is described by Wilson (2008), and there

is also guidance provided by Baker et al (2009) and Welburn et al (2012). It should be noted that diffusive

migration will govern VOC migration through a well-sealed membrane as the membrane effectively

prevents advective flow. Conversely advection will be the mechanism that drives flow through any defects

in the membrane.

Thick reinforced concrete floor slabs provide good resistance to vapour ingress in many cases and the

combination of slab and membrane should be incorporated into the risk assessment (taking into account

any construction joints and cracks around penetrations, whether joints are well sealed etc). Knowledge of