newcastle coal infrastructure group coal export terminal

advertisement

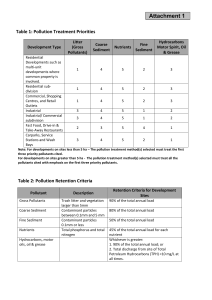

NCIG OPERATION WATER MANAGEMENT PLAN NEWCASTLE COAL INFRASTRUCTURE GROUP COAL EXPORT TERMINAL OPERATION WATER MANAGEMENT PLAN May 2010 Version 2 Development No. 06 0009 NCIG OPERATION WATER MANAGEMENT PLAN TABLE OF CONTENTS 1 INTRODUCTION ........................................................................................................................................ 3 1.1 1.2 2 Purpose .................................................................................................................................................................. 3 Scope...................................................................................................................................................................... 3 BACKGROUND .......................................................................................................................................... 4 2.1 2.2 2.3 NCIG Overview........................................................................................................................................................ 4 Location.................................................................................................................................................................. 5 Project Description and Operational Activities ......................................................................................................... 7 2.3.1 2.3.2 2.3.3 3 IMPLEMENTATION AND CONTROL STRATEGIES ........................................................................................... 7 3.1 Roles and Responsibilities ....................................................................................................................................... 7 3.1.1 3.1.2 3.1.3 3.1.4 3.2 Erosion and Sediment Control ............................................................................................................................... 15 3.4 Amenities Water Management .............................................................................................................................. 17 3.4.1 3.4.2 3.4.3 3.4.4 3.4.5 3.4.6 3.4.7 3.4.8 3.4.9 Fire System...................................................................................................................................................................... 17 Potable Water ................................................................................................................................................................. 17 Dust Suppression System .................................................................................................................................................. 17 Sewer System .................................................................................................................................................................. 17 Workshops and Vehicle Wash bays .................................................................................................................................... 17 Trade and Operation Waste .............................................................................................................................................. 17 Bore Water ..................................................................................................................................................................... 18 Equipment Laydown Storage and Car Parks ....................................................................................................................... 18 Treated Wastewater ........................................................................................................................................................ 18 MONITORING ......................................................................................................................................... 18 Water Monitoring Program ................................................................................................................................... 18 4.2 4.3 Data Review and Validation .................................................................................................................................. 23 Investigation Procedures for Exceedance of Water Quality Criteria or Nonconformance ......................................... 24 Surface and Discharge Monitoring Locations ...................................................................................................................... 18 Groundwater Monitoring Locations ................................................................................................................................... 18 Stormwater and Pond Monitoring Parameters ................................................................................................................... 20 Erosion and Sediment Control Monitoring .......................................................................................................................... 23 CORRECTIVE ACTIONS ............................................................................................................................. 24 REPORTING ............................................................................................................................................ 24 6.1 6.2 6.3 6.4 Incident Reporting ................................................................................................................................................ 24 Recording Pollutant Complaints............................................................................................................................. 24 Internal Reporting ................................................................................................................................................. 25 External Reporting/Notification............................................................................................................................. 25 AUDIT AND REVIEW ................................................................................................................................ 25 7.1 7.2 8 Sources of Soil Erosion ...................................................................................................................................................... 16 Erosion and Sediment Control Strategies............................................................................................................................ 16 Specifications for Sediment Control Structures .................................................................................................................... 16 Erosion and Sediment Control Plans .................................................................................................................................. 16 4.1 4.1.1 4.1.2 4.1.3 4.1.4 7 Water Requirements and Supply ......................................................................................................................................... 8 Water Management System ............................................................................................................................................... 8 Site Water Balance .......................................................................................................................................................... 10 Local Hydrology ............................................................................................................................................................... 10 Water Management Infrastructure ................................................................................................................................... 12 Groundwater Management .............................................................................................................................................. 13 Internal Drainage and Stormwater Controls ....................................................................................................................... 13 Potential Water Quality Impacts ....................................................................................................................................... 14 3.3 3.3.1 3.3.2 3.3.3 3.3.4 5 6 General Manager .............................................................................................................................................................. 7 Operation/Engineering Manager ........................................................................................................................................ 7 NCIG Environmental Representative .................................................................................................................................... 8 Employees and Contractors ................................................................................................................................................ 8 Water Management ................................................................................................................................................ 8 3.2.1 3.2.2 3.2.3 3.2.4 3.2.5 3.2.6 3.2.7 3.2.8 4 Train Unloading ................................................................................................................................................................. 7 Coal Handling and Stockpiling ............................................................................................................................................. 7 Shiploading ....................................................................................................................................................................... 7 Audits ................................................................................................................................................................... 25 Review Process ..................................................................................................................................................... 25 REFERENCES ........................................................................................................................................... 26 Document No. Date Effective Review Date Page Number NCIG_HSEC_MPL_8.04 OWMP May 2010 May 2011 Page 2 of 26 NCIG OPERATION WATER MANAGEMENT PLAN 1 INTRODUCTION In accordance with Condition 1.10 of the Project Approval (06_0009), the specified time period for this Operation Water Management Plan (OWMP) is for the operational life of the Newcastle Coal Infrastructure Group (NCIG) Coal Export Terminal (CET). This OWMP describes the objectives, concepts and design criteria for site water management, erosion and sediment control structure, and aims to ensure that appropriate environmental management practices are followed during site operations. This plan will be first utilised for Stage 1 of operation, up to 30 Mtpa capacity. Any plan, program or approval required for Stage 2 (up to 66 Mtpa) will be developed and implemented, and where applicable submitted, on a progressive basis. The OWMP has been developed as a supplementary management plan to the NCIG Operation Environmental Management Plan (OEMP). The context of the OWMP is outlined in the OEMP. The OWMP applies to the coal handling and storage operations of the NCIG site in terms of train unloading, coal handling, stock piling and shiploading. This OWMP has been prepared in accordance with the requirements of the Guidelines for the Preparation of Environmental Management Plans (DIPNR 2004), and has been prepared in accordance with conditions 2.41,2.42, 2.49, 2.50, 2.51, 2.52, and 7.6 (c) of the Minister for Planning Project Approval 06_0009. The OWMP will be progressively developed as Operation Water Management requirements change over time. This OWMP applies to all NCIG personnel and contractors associated with NCIG operations. 1.1 Purpose The purpose of this OWMP is to: • • • • • • • • Minimise and control the impact of NCIG operation activities on surrounding water bodies via the separation of surface water runoff generated from within the active Project operational areas, from that generated from surrounding areas; Control site erosion and sediment runoff; Contain and re‐use water on‐site; Implement water management controls to minimise the potential for impacts to off‐site water resources; Ensure compliance with EPL 12693 and Project Approval requirements; Clearly define the responsibilities and actions required to respond to environmental incidents; Enable NCIG to maintain environmental amenity and a healthy relationship with the local community, regulatory authorities; and Prevent discharges into the Hunter River during operation of the Project. 1.2 Scope Condition 7.6 (c) of the Project Approval requires the preparation, submission and approval of an OWMP for NCIG operational activities. This condition is outlined in Table 1 and includes an indication of where the requirements have been addressed in this OWMP. Document No. Date Effective Review Date Page Number NCIG_HSEC_MPL_8.04 OWMP May 2010 May 2011 Page 3 of 26 NCIG OPERATION WATER MANAGEMENT PLAN Table 1. Conditions of Project Approval (06_0009) CONDITION CONDITION DETAIL SECTION OF OWMP 2.41 Except as may be expressly provided under the provision of an Environmental Protection Licence for the project, the Proponent shall comply with section 120 of the Protection of the Environment Operations Act 1997 which prohibits the pollution of waters. This OWMP 2.42 Unless otherwise agreed by the Director‐General, the Proponent shall design, construct, maintain and operate surface water and stormwater management infrastructure on the Site to accommodate a 1 in 100 ARI rainfall event, and shall not permit the discharge of any water from the site to the Hunter River unless expressly provided under the provision of an Environmental Protection License. Section: 3.2.4, 3.2.5, 3.3.3 2.49 All stormwater and surface water management infrastructure on the Site intended to manage actual or potentially contaminated water shall be lined with a low‐permeability material to ninimise potential leakage. Collected stormwater shall be reused on Site for beneficial purposes such as the wetting of coal to reduce dust emissions from the site. Section: 3.2.7, 3.3.3. 2.50 In the event that stormwater runoff collection cannot meet the water demand of the Site, treated wastewater, if available from the relevant water authority, shall be used preferentially over potable water for the purpose of dust control, unless otherwise agreed by the Director‐ General. Section: 3.2.1, 3.4.10 2.51 All machinery wash down waters and amenities wastewater shall be directed to sewer (subject to Hunter Water Corporation approval), or to an appropriately licensed liquid waste disposal facility. Section: 3.4.6 2.52 The Proponent shall design, install, maintain and operate rainwater tanks for the collection of water for domestic and potable uses on the Site. Collected rainwater shall be used preferentially to external potable water supplies. Section: 3.4.2 7.6 As part of the Operation Environmental Management Plan for the project required under condition 7.5 of this approval, the Proponent shall prepare and implement a Water Management Plan to outline the water management system for the Site. The Plan shall include, but not necessarily be limited to: This OWMP i) predicted Site water balance including the water supply system; Section: 3.2.3 ii) details regarding water management structures such as settling ponds, water tanks and the water management system for dredge sea water; Section: 3.2.5 iii) locations and design specifications for all water diversions from undisturbed runoff areas including channel design and stabilization, sediment retention storages and other structures; Section: 3.2.5 iv) details on the internal drainage system including bunding, drainage channels, dewatering sumps and any pipelines; Section: 3.2.7 v) procedures for the management of groundwater encountered on Site and any temporary dewatering facilities; and Section: 3.2.6 vi) procedures to be implemented to minimise potential surface water impacts. Section: 3.2.5, 3.2.8 2 BACKGROUND 2.1 NCIG Overview The following six companies are shareholders of NCIG: • • • • • • BHP Billiton (through Hunter Valley Energy Coal Limited); Centennial Coal Company Limited; Donaldson Coal Pty Limited; Peabody Energy Australia Coal Pty Limited; Felix Resources Limited (formerly White Mining Limited); and Whitehaven Coal Mining Pty Ltd. Document No. Date Effective Review Date Page Number NCIG_HSEC_MPL_8.04 OWMP May 2010 May 2011 Page 4 of 26 NCIG OPERATION WATER MANAGEMENT PLAN 2.2 Location The NCIG CET is located on Kooragang Island in Newcastle, New South Wales (NSW) approximately 6 km north‐west of the Newcastle central business district (CBD) (Figure 1). The project is located on lands that are leased from the Newcastle Port Corporation. The site comprises part of the Kooragang Island Waste Emplacement Facility (KIWEF) and reclaimed land located between the south arm of the Hunter River and existing industrial development on Kooragang Island. Document No. Date Effective Review Date Page Number NCIG_HSEC_MPL_8.04 OWMP May 2010 May 2011 Page 5 of 26 NCIG OPERATION WATER MANAGEMENT PLAN Figure 1. Location of the Newcastle Coal Infrastructure Group Coal Export Terminal. Document No. Date Effective Review Date Page Number NCIG_HSEC_MPL_8.04 OWMP May 2010 May 2011 Page 6 of 26 NCIG OPERATION WATER MANAGEMENT PLAN 2.3 Project Description and Operational Activities The Project includes the operation of a CET delivering up to 66 million tonnes per annum (Mtpa), including associated rail and coal handling infrastructure and wharf/shiploading facilities on the south arm of the Hunter River. The following three major activities are undertaken during operations: 2.3.1 Train Unloading The operation only receives coal by rail transportation. Coal trains enter the site from the Kooragang Island main line, and travel along rail spurs and empty their coal wagons into one of two train unloading stations. Empty trains then travel around the rail loop and rejoin the mainline. Each train unloading station has the capacity to unload up to approximately 8,500 tonnes of coal per hour. Based on a nominal 7,000 tonne capacity train, an average of 26 trains may be unloaded each day. Allowing time to maneuver trains and equipment, NCIG estimate that the site has the capacity to receive up to a maximum of 40 trains per day. 2.3.2 Coal Handling and Stockpiling Coal is transferred from the train unloading stations to the coal storage area for stockpiling via stacking conveyors or conveyed directly to the wharf facilities and ship loaders. Up to four combined stacker/reclaimers are used to stack coal onto the coal stockpiles and reclaim coal via a bucket‐wheel. The combined stacker/reclaimers each have a typical stacking and reclaiming capacity of 8,500 tonnes per hour, however, this may peak at up to 10,000 tonnes per hour. Coal is reclaimed from the coal storage area and conveyed to the wharf facilities and ship loaders as required. 2.3.3 Shiploading Ship loaders operate at a 10,500 tonne per hour nominal capacity and peak at up to 12,500 tonnes per hour when drawing coal from the buffer bins. Based on an 180,000 tonne capacity ship (Cape class), and allowing for the time taken to maneuver ships and equipment, NCIG expects that up to 12 ships would be loaded per week. If smaller vessels are utilised to export coal from the NCIG CET, then the number of vessel movements per week would increase. 3 IMPLEMENTATION AND CONTROL STRATEGIES The water management strategy for the Project is based on: • • • The separation of surface water runoff generated from within the active Project operational areas from that generated by surrounding areas; Containment and re‐use of water on‐site; and Implementation of water management and erosion controls to minimise the potential for impacts to off‐site water resources. 3.1 Roles and Responsibilities 3.1.1 • 3.1.2 • • • General Manager Approve the OWMP Operation/Engineering Manager Install and maintain water management infrastructure; Report actual and potential environmental incidents to the Environmental Representative; Consult with the Environmental Representative to determine appropriate environmental management strategies and contingency measures required by the OWMP; Document No. Date Effective Review Date Page Number NCIG_HSEC_MPL_8.04 OWMP May 2010 May 2011 Page 7 of 26 NCIG OPERATION WATER MANAGEMENT PLAN • • 3.1.3 • • • • • • • • • 3.1.4 • • • Consult with the Environmental Representative with respect to the management of contractors for construction and maintenance activities that may affect the integrity and effectiveness of the OWMP; and Report actual and potential environmental incidents to the Environmental Representative. NCIG Environmental Representative The principal contact point in relation to the OWMP Audit or arrange an audit of activities associated with the OWMP on a regular basis and submit a formal report to the General Manager. Maintain Water monitoring results in a database Investigate OWMP non conformances or water quality exceedances Determine appropriate management strategies and implement contingency measures in consultation with the relevant operations manager. Prepare Erosion and Sediment Control Plans (ESCP) for any major construction works prior to land disturbance activities. Complete all required Internal and External reports required by the OWMP Investigate and report on all incidents or complaints relevant to the OWMP Maintain a database of incidents and complaints related to the OWMP Employees and Contractors Undertake operation activities in accordance with relevant NCIG policies, procedures, management protocols, plans, statutory and contract requirements; Implement appropriate environmental management measures; and Report actual and potential environmental incidents to the Environmental Representative. 3.2 Water Management The primary design goal of the Project water management protocol is that of no discharge to the Hunter River during operation of the Project. The water management protocol will be progressively developed as Project water management requirements change over time. 3.2.1 Water Requirements and Supply Water supply requirements during operation of the Project will be met from stormwater contained on site and water purchased from the Hunter Water Corporation. Water will be used for the following applications: • • • • • • Dust suppression on road surfaces, coal stockpiles and at conveyor transfer points; Washdown of site vehicles, conveyors, wharf areas, shiploaders and other coal handling equipment; Belt washing; Landscape irrigation; Fire protection systems; and Employee amenities and other minor potable water uses. Water will be recycled on site to reduce the quantity of water purchased from the Hunter Water Corporation. If required, alternative water supply sources will be investigated during the life of the Project including the beneficial use of treated sewage effluent from the Hunter Water Corporation or local bore water. Any such alternative sources of Project water supply would be subject to separate environmental assessment and approvals. Potable water at the Project will be supplied by Hunter Water Corporation’s local water supply system. The Hunter Water Corporation will also supply water for dust suppression, fire protection and washdown activities to supplement the Project water management system as required. 3.2.2 Water Management System The Project water management system is shown in schematic form on Figure 2. This will be progressively developed as Project water management requirements change over time. Document No. Date Effective Review Date Page Number NCIG_HSEC_MPL_8.04 OWMP May 2010 May 2011 Page 8 of 26 NCIG OPERATION WATER MANAGEMENT PLAN Figure 2. Schematic of the NCIG project water management system. Document No. Date Effective Review Date Page Number NCIG_HSEC_MPL_8.04 OWMP May 2010 May 2011 Page 9 of 26 NCIG OPERATION WATER MANAGEMENT PLAN 3.2.3 Site Water Balance A site water balance was developed by NCIG towards Environmental Assessment (NCIG, 2006) to determine the water demand requirements for the Project during operation at 66 Mtpa. The model quantified the water budget for three weather scenarios based on 20 years (1985 to 2005) of historical rainfall records for the Newcastle area from the Bureau of Meteorology. Results of the water balance model are shown in Table 2. The amount of stormwater runoff that will be captured for on‐site use is expected to vary from 174 to 922 ML/annum. Based on the results of the site water balance, the average make‐up water demand (i.e. water purchased from Hunter Water Corporation) is estimated to be approximately 406 ML/annum. The governing philosophy of the water balance for the NCIG site is that stormwater and rainwater captured will be utilized preferentially to external potable water sources (i.e. water from Hunter Water Corporation). The water purchased from Hunter Water Corporation may incorporate treated effluent depending upon availability. Table 2. NCIG Site Water Balance LOW RAINFALL SCENARIO AVERAGE RAINFALL HIGH RAINFALL SCENARIO (ML/ANNUM) SCENARIO (ML/ANNUM) (ML/ANNUM) WATER SUPPLY Stormwater runoff/on‐site recycled water Water from Hunter Water Corp 174 728 460 406 922 126 Total 902 866 1048 WATER DEMAND Dust suppression Washdown Belt cleaning Landscape irrigation Potable water (employee amenities, ship supply, fire services 686 19.7 68.3 1.6 126 650 19.7 68.3 1.6 126 615 19.7 68.3 1.6 126 Total 902 866 831 Local Hydrology For the purposes of identifying off‐site water resources, a description of the existing local hydrology for the three main Project areas is provided below (Figure 3). Document No. Date Effective Review Date Page Number NCIG_HSEC_MPL_8.04 OWMP May 2010 May 2011 Page 10 of 26 NCIG OPERATION WATER MANAGEMENT PLAN Figure 3. The drainage layout, surface water features and water monitoring sites for the NCIG site. Document No. Date Effective Review Date Page Number NCIG_HSEC_MPL_8.04 OWMP May 2010 May 2011 Page 11 of 26 NCIG OPERATION WATER MANAGEMENT PLAN Rail Infrastructure Corridor Existing surface water features in the vicinity of the rail infrastructure corridor comprise waterbodies created by the existing Kooragang Island mainline rail embankment, emplacement cells associated with the KIWEF and a number of depressions in the KIWEF landform that intermittently fill with water in response to rainfall runoff. There is also a drainage channel adjacent to the Kooragang Island mainline which drains to the south arm of the Hunter River. Deep Pond is a large waterbody in this area and is connected to a series of ponds to its south‐east via drainage lines (Figure 3). Stormwater from the drainage system along the rail infrastructure corridor will drain into the existing drainage system across the KIWEF. An existing drain also conveys water to the Hunter River on the eastern side of the KIWEF site. Coal Storage Area The Project coal storage area is relatively flat with designed and engineered fall from east to west. The stockyard area is drained by a centrally located subsoil drainage network that conveys excess stockpile water to the western end and site drainage system. There are three primary stormwater channels including: south‐north concrete dish drain on the west end of the stockyards, a west‐east channel on the northern boundary of the coal storage area (running into the primary settling pond), and a north‐south concrete‐lined stormwater channel along the eastern boundary of the Project site. The south‐north channel drains into the west‐east channel which delivers drainage water to the west‐east aligned primary and secondary ponds. Overflow from the final pond is channeled to the north‐south channel which in‐turn drains to the south arm of the Hunter River. Wharf Facilities and Shiploader Area The Project wharf facilities and shiploader area is located on the south arm of the Hunter River. This area is relatively flat and drains to a detention pond on its eastern side before being pumped into the stockyard water management network (Figure 3). The south arm of the Hunter River is the dominant natural surface water feature in this area and no water from the wharf facilities and shiploader area will be directed to the South Arm of the Hunter River. 3.2.4 Water Management Infrastructure A network of stormwater drains and stormwater settlement ponds (primary and secondary) are used to manage runoff on and around the site. All site water management structures are lined with low permeability materials (e.g. compacted clay or geo‐membrane) to minimise the potential for leakage. Stormwater captured on site is designated as ‘clean’ or ‘dirty’ stormwater. The ‘clean’ stormwater collection area is considered to be the rail network site excluding those areas in the vicinity of the unloading station and coal transfer system (Figure 3). All other areas of stormwater capture on site are designated ‘dirty’ stormwater which is captured and reused by the water management system. Stormwater runoff from areas external to the Project site are directed around the Project infrastructure areas by table drains and culverts to the existing stormwater drainage system on Kooragang Island. Stormwater runoff collected on the Project infrastructure areas is diverted through sediment control structures and/or to stormwater settlement ponds. The coal storage area is sloped with dedicated drains located along the pads and berms. A sub‐grade drainage system is incorporated into the coal stockpile pads to capture water infiltrating through the coal stockpiles. The sub‐grade drainage system comprises of a series of underground drains, pits and transfer pumps for controlling drainage from the coal storage area. Lined sumps are used at the end of the open drains to act as pollutant traps. The primary and secondary settling ponds, consisting of settlement, storage and overflow ponds, are constructed to the north of the coal storage area. The settling pond captures sediments not trapped in concrete sumps or open drains. Water in the site water pond is pumped to a raw water tank with a Document No. Date Effective Review Date Page Number NCIG_HSEC_MPL_8.04 OWMP May 2010 May 2011 Page 12 of 26 NCIG OPERATION WATER MANAGEMENT PLAN capacity of up to 4 mega litres (ML). The raw water tank stores water for re‐use on‐site for purposes such as dust suppression, fire protection, plant washdown and landscape management. A 500 kilolitre (kL) potable water tank is installed adjacent to the raw water tank for potable water supply purposes (e.g. amenities and ship potable water supply). A 2 ML fire services tank is also installed for emergency fire fighting situations. Pumping stations are located adjacent to the water tanks for water reticulation on‐site. Stormwater runoff from the Project rail infrastructure area is diverted via table drains along the Project rail infrastructure corridor to localised sediment control structures/settlement ponds. Once runoff has passed through these structures it reports to the existing stockpile water management system. Sediment control structures/settlement ponds are also installed at the administration and workshop area and the wharf facilities and shiploaders. Water collected in these ponds is transferred via pump and pipeline to the primary and secondary ponds. Consistent with the design goal of no discharge to the Hunter River during operations, the primary and secondary settlement ponds are designed and constructed with sufficient capacity to contain a 1 in 100 year average recurrence interval (ARI) rainfall event. All Project water management structures are operated in accordance with the requirements of the Project EPL 12693. During operations of the NCIG CET, dredging reclamation activities will not be undertaken on the site, and related infrastructure is therefore not included in the site water management network. 3.2.5 Groundwater Management The Project site includes a relatively shallow groundwater table in areas of fill from previous landuse activities. Consequently, any interception of the groundwater table during operations will need to be managed. NCIG has incorporated into the design of the Project a comprehensive suite of methods and design systems (including contingency measures): • • • • • 3.2.6 Any groundwater that is dewatered from future excavations and is not considered suitable for re‐ use will be temporarily stored in dedicated cells with low permeability liners (e.g. compacted clay or geo‐membrane) before being treated for re‐use and/or removed from site by an appropriately licensed contractor. These facilities will be designed and constructed on the basis of the water quality and quantity encountered during the excavation process; The use of piled foundations together with a jet‐grouted base and secant pile and/or diaphragm sub‐surface perimeter walls was used in construction of the train unloading stations and adjacent conveyors to minimise groundwater inflow or connection; Incorporation of a low permeability capping layer into the rail embankment formation to minimise infiltration; Establishment of groundwater bores to monitor groundwater levels, and water quality around the perimeter of the coal storage area and along the rail infrastructure corridor; and If the groundwater monitoring program indicates the need, the implementation of groundwater management contingency measures such as: localised temporary pumping of groundwater for subsequent detention, dilution, evaporation, treatment and/or disposal by an appropriately licensed contractor (depending on water quality and quantity); and/or The construction of localised sub‐surface groundwater barriers (e.g. bentonite filled trench or geo‐membrane) to control groundwater migration. Internal Drainage and Stormwater Controls A network of stormwater structures are used to manage runoff on and around the site. All long‐term site water management structures are lined with low permeability materials (e.g. compacted clay or geo‐ membrane) to minimise the potential for leakage. Water management structures are designed and constructed with sufficient capacity for a 1 in 100 year average recurrence interval (ARI) rainfall event. Project water management structures are also designed to operate in accordance with Environment Document No. Date Effective Review Date Page Number NCIG_HSEC_MPL_8.04 OWMP May 2010 May 2011 Page 13 of 26 NCIG OPERATION WATER MANAGEMENT PLAN Protection Licence (EPL) No. 12693, obtained from the Department of Environment Climate Change and Water (DECCW). A major component of the OWMP is the capture and management of site water for water reuse in dust suppression of coal stockpiles as per the Operation Dust Management Plan. In accordance with Condition 2.41, Schedule 2 of Project Approval (06_0009), Project water management structures are designed to operate to comply with Section 120 of the Protection of the Environment Operations Act, 1997. 3.2.7 Potential Water Quality Impacts Surface water runoff from disturbance areas during site operations and construction modifications could potentially contain sediments, soluble salts, fuels, oils, lubricants and other contaminants. The potential surface water quality impacts, contaminants, control measures and responsible personnel that relate to these potential impacts from each area of the Project site are summarised in Table 3. There are two major risk groups that relate to potential water quality impacts: • Risk groups (solid): Coal, toxic contaminants, general sediments, general solid wastes; and • Risk groups (liquid): Oils, fuels, lubricants, hydrocarbons, groundwater preloading and settlement, surface/site water sprays, rainfall and water pH levels. Table 3. Potential water quality impacts for the NCIG site POTENTIAL MITIGATION AND PERSONNEL CONTAMINANT CONTROL MEASURES RESPONSIBLE Sediments containing soluble salts, heavy metals, organic contaminants, fuels, oils and lubricants. Appropriate training, regular monitoring, and drainage controls. Localised sediment control structures. Operation Manager, Engineering Manager and Environmental Representative Uncontrolled drainage of runoff from access roads, operations and construction improvement areas to downstream waterbodies within the KIWEF. Uncontrolled drainage of runoff from exposed soils within the existing KIWEF to downstream waterbodies. Potential erosion and sedimentation resulting from runoff from the rail corridor and associated drainage system. PROJECT SITE Rail Infrastructure Corridor (rail spurs, loops and train unloading station) POTENTIAL IMPACT SCENARIO Uncontrolled drainage of sediment laden runoff to downstream waterbodies within the Kooragang Island Waste Emplacement Facility (KIWEF) during rail operations and construction improvements of rail embankments. Release/spill into downstream waterbodies. Coal, diesel, lubricants and hydrocarbons. Appropriate training, regular monitoring, drainage controls and oil separators. Coal Storage Area and Administration Area Uncontrolled drainage to downstream waterbodies during operation or construction improvements of the coal storage and administration areas. Contaminated sediments containing soluble salts, heavy metals, organic contaminants, fuels, oils, lubricants and Appropriate training, regular monitoring, drainage controls and oil separators. Site designed for zero discharge, monitoring of licensed discharges. Operation Manager, Engineering Manager and Environmental Representative Document No. Date Effective Review Date Page Number NCIG_HSEC_MPL_8.04 OWMP May 2010 May 2011 Page 14 of 26 NCIG OPERATION WATER MANAGEMENT PLAN Uncontrolled drainage of runoff from access roads, operations and construction improvement areas to downstream waterbodies. low pH water. Spillage/overflow of site water to downstream waterbodies due to unplanned discharge from water management system or failure of water management component. Release/spill into downstream waterbodies due to, rupture of fuel tank (diesel/petrol) Sediments, coal, diesel, lubricants and hydrocarbons. Appropriate training, regular monitoring, drainage controls and oil separators. Site designed for zero discharge, monitoring of licensed discharges. Storage in accordance with Australian Standards and NSW Legislation. Operation Manager, Engineering Manager and Environmental Representative Wharf Facilities and Shiploader Area Uncontrolled drainage of sediment laden runoff to the south arm of the Hunter River during operation and construction improvements of the berths and wharf structure, excavation on or near the banks of the South Arm of the Hunter River. Sediments, soluble salts, fuels, oils and grease. Appropriate training, regular monitoring, and drainage controls. Site designed for zero discharge, monitoring of licensed discharges. Operation Manager, Engineering Manager and Environmental Representative Uncontrolled drainage of runoff to the South Arm of the Hunter River from access roads. Release/spill into the South Arm of the Hunter River Sediments, coal, diesel, lubricants and hydrocarbons. Note: If further construction is required on site (other than minor updates and improvements), implementation of Construction Management Protocol (CMP) documentation will be required. 3.3 Erosion and Sediment Control The following principles underpin the approach to erosion and sediment controls for the NCIG site to protect adjacent wetland areas, Deep Pond and the Hunter River: • • • • • • • • • • Minimise surface disturbance, and restrict access to undisturbed areas. Minimise or limit construction compounds where possible. Limit soil stockpiles, and prevent their location within 10 m of watercourses or stormwater drains. Separate runoff from disturbed and undisturbed areas where practicable. Implementation of surface drains to facilitate the efficient transport of surface runoff and utilisation of existing stormwater systems. Implementation of the site drainage network including perimeter bunds, internal bunds, primary settling ponds and hydraulically controlled discharge structures. Implementation of silt drains and diversions in areas where sediment basins are not appropriate. Implementation of secondary settling ponds, site water pond and sediment dams to contain runoff up to specified design criterion. Install a silt curtain in the south arm of the Hunter River local to the disturbance area. Refuel plant and machinery within bunded areas where ever possible The above principles take into account the general recommendations for site drainage works presented in Managing Urban Stormwater: Soils and Construction – Volume 1 (Landcom, 2004). Document No. Date Effective Review Date Page Number NCIG_HSEC_MPL_8.04 OWMP May 2010 May 2011 Page 15 of 26 NCIG OPERATION WATER MANAGEMENT PLAN All erosion, sediment and pollution control infrastructure is maintained for the duration of any construction activities during operations and until such time as all ground disturbed by the works has been stabilised and rehabilitated so that it no longer acts as a source of sediment, in accordance with Condition 2.44, Schedule 2 of Project Approval (06_0009). 3.3.1 Sources of Soil Erosion Activities that have the potential to cause or increase soil erosion at site are primarily due to exposure of soils during operational activities in the delivery of up to 66 Mtpa. Effective erosion control requires the successful management of the following components during operation: water management infrastructure including site drainage works, stormwater settlement ponds, primary and secondary settling ponds, site water pond and effective management of water tanks and stockpile spray system. Further to the above, additional details of sub‐activities to be undertaken during operations that have the potential to cause or increase soil erosion at the site include activities such as; bulk earthworks, reclamation works; civil/concreting; and structural/mechanical installation. 3.3.2 Erosion and Sediment Control Strategies The erosion and sediment control principles and design criteria for the Project operation are described in the following sub sections. Specific erosion and sediment control measures for individual Project components will be provided progressively in detailed plans as required. 3.3.3 Specifications for Sediment Control Structures In accordance with Condition 2.42 of the Project Approval, unless otherwise agreed by the Director‐ General, NCIG will design, construct, maintain and operate surface water and stormwater management infrastructure on the site to accommodate a 1 in 100 ARI rainfall event. In accordance with Condition 7.3 (b), Schedule 2, of the Project Approval (06_0009), all elements of the site drainage network will include appropriately‐sized stormwater controls, in accordance with Managing Urban Stormwater: Soils and Construction – Volume 1 (Landcom, 2004). The general design criteria for sediment control structures are summarised in Table 4. Table 4. NCIG Sediment Control Structures – General Capacity Requirements SEDIMENT CONTROL STRUCTURE FUNCTION DESIGN CAPACITY Upslope diversion drains Reduce runoff from undisturbed areas onto disturbed or operational areas. Peak flow calculated for 1 in 100 year critical duration rainfall event. Downslope collection drains Intercept and convey disturbed area runoff water to sediment dams. Peak flow calculated for 1 in 100 year critical duration rainfall event. Sediment dams Containment of sediment‐laden runoff. Capacity to store the runoff produced from the 1 in 100 year critical duration rainfall event and suitable sediment storage capacity in accordance with Landcom (2004). 3.3.4 Erosion and Sediment Control Plans Erosion and Sediment Control Plans (ESCP) will be prepared for any major construction works at the direction of the Environmental Representative prior to land disturbance activities. These ESCPs will follow the guidelines nominated in Section 4.3 Erosion and Sediment Control Principles. The ESCP will provide detailed specifications for each sediment control structure. Document No. Date Effective Review Date Page Number NCIG_HSEC_MPL_8.04 OWMP May 2010 May 2011 Page 16 of 26 NCIG OPERATION WATER MANAGEMENT PLAN 3.4 Amenities Water Management 3.4.1 Fire System A comprehensive fire system has been installed on the NCIG site which includes spray and deluge components. This system provides protection for all areas of the CET infrastructure and is supplied by the Hunter Water Corporation supply network. 3.4.2 Potable Water Potable water is primarily sourced from the Hunter Water Corporation system and is stored in a 500 kilolitre (kL) potable water tank. In accordance with condition 2.52, rain water tanks have been installed and maintained on the NCIG site for the collection of water for domestic uses. Collected rainwater is utilised to supplement the Hunter Water Corporation supply and is used preferentially to external potable water supplies for targeted domestic usage. This system is designed to minimise the usage of potable water and to maximise the reuse of water collected on site. 3.4.3 Dust Suppression System In the event of collected site water levels falling below the level of requirement of water supply to the dust suppression system, treated water, if available, will be used preferentially to external water supplies for the purpose of dust suppression, unless otherwise agreed by the Director‐General. 3.4.4 Sewer System The NCIG CET site is connected to the Hunter Water Corporation sewerage network. A sewerage collection tank is located at the administration building which accumulates wastewater from the administration, workshop and wharf areas. Sewerage at the rail infrastructure area will be serviced via pump‐out facilities. 3.4.5 Workshops and Vehicle Wash bays The workshop and truck washdown areas have purpose built oil/water separator systems installed which will be inspected and maintained on a regular basis. All machinery wash down waters and amenities wastewater must be directed to sewer (subject to Hunter Water Corporation approval), or to an appropriately licensed liquid waste disposal facility. Waste hydrocarbons collected from site activities and oil/water separation will be collected and stored in a 12,000 litre (L) waste oil tank, before being removed by licensed waste transporters on a periodic basis. 3.4.6 Trade and Operation Waste Measures to avoid and minimise the generation of wastes and promote waste re‐use and recycling during operations of the Project will include: • • • Waste avoidance – practices will be developed that reduce the amount of waste on‐site, via selective purchasing procedures by store personnel and the use of bulk purchasing, where practicable; Material reuse – reuse of recyclable or reusable materials where practicable; and Recycling – materials such as metals, oil, timber, plastics, glass and paper will be recycled where practicable. In accordance with Conditions 2.54 and 2.56, Schedule 2 of the Project Approval (06_0009), all waste materials removed from the site will be directed to a waste management facility lawfully permitted to accept the materials. In accordance with Condition 2.57, Schedule 2 of the Project Approval (06_0009), waste will not be received at the site for storage, treatment, processing or reprocessing or disposal, except as expressly permitted in an appropriate licence. In addition, NCIG will comply with the requirements of EPL No. 6437 as it relates to the on‐going management of the KIWEF. It is the responsibility of all contractors to remove trade waste from site in accordance with NCIG procedures, or to engage suitably qualified and licensed waste management providers. Document No. Date Effective Review Date Page Number NCIG_HSEC_MPL_8.04 OWMP May 2010 May 2011 Page 17 of 26 NCIG OPERATION WATER MANAGEMENT PLAN 3.4.7 Bore Water Bore water will not be utilised on the NCIG site unless an appropriate environmental assessment has been undertaken and approval received. 3.4.8 Equipment Laydown Storage and Car Parks Water runoff from the equipment laydown storage area and car parks will be collected in a storage detention pond. Water will then undergo oil separation prior to being pumped into the stockyard water management network. 3.4.9 Treated Wastewater Treated wastewater is currently not available to supplement collected on site stormwater for reuse. In accordance with Condition 2.50, NCIG will continue to liaise with Hunter Water Corporation on the matter to assess the potential future use of this water resource. 4 MONITORING Monitoring conducted under this protocol will include Water, Erosion and Sediment control. 4.1 Water Monitoring Program The Water Monitoring Program for the site will involve the monitoring of water quality and water levels at discharge locations, groundwater locations, primary and secondary ponds and at drainage, erosion and sediment control structures. 4.1.1 Surface and Discharge Monitoring Locations Selected water monitoring locations are nominated as locations 1, 2 and 3, as per Figure 4. An outline of the monitoring program water quality levels are provided in Tables 5, 6, 7 and 8 as per parameters for monitoring under EPL No. 12693 and Australian Standards. 4.1.2 Groundwater Monitoring Locations Groundwater quality monitoring will be undertaken on a six monthly basis at groundwater monitoring bore GW1 (Figure 4). The monitoring results will be compared to baseline water quality records and the Australian and New Zealand Environment and Conservation Council (ANZECC) (2000) aquatic ecosystem protection level triggers described in Tables 5, 6 7 and 8. If an exceedance of the applicable ANZECC criteria is identified that is not reflected in existing baseline data and is likely to have been caused by Project operation activities, immediate consideration will be given to implementing additional groundwater management controls. The requirement for additional groundwater controls would be identified via implementation of the Operation Environmental Monitoring Plan (see OEMP). Table 5. NCIG Water Monitoring Program Guidelines MONITORING FREQUENCY PARAMETERS METHODOLOGY PERSONNEL LOCATIONS Primary and secondary settling ponds. Overflow pond.1 RESPONSIBLE Monthly During period of heavy rainfall (i.e. more than 20 mm of rainfall in a 24 hour period). pH Electrical conductivity (EC) Turbidity (NTU) Temperature (°C) Water level. Pond 1 min xm max xm Pond 2 min xm max xm Pond 3 min xm max xm Pond 4 min xm max xm Environmental consultant (metering) Environmental Representative Visual Environmental Representative Document No. Date Effective Review Date Page Number NCIG_HSEC_MPL_8.04 OWMP May 2010 May 2011 Page 18 of 26 NCIG OPERATION WATER MANAGEMENT PLAN Surface water monitoring site.1 Monthly Ground water 1 monitoring site. Six monthly Drainage, erosion and sediment control infrastructure. Monthly Collection sumps Weekly pH Electrical conductivity (EC) Turbidity (NTU) Temperature (°C) Environmental consultant (metering) Environmental Representative Environmental consultant (metering) Environmental Representative pH; EC; TDS; and TSS. Table 5 and 6 Structural stability and effectiveness in controlling sediment migration. Visual Environmental Representative Level of collected sediment Visual Environmental Representative 1 Monitoring locations are shown on Figure 4. Table 6. NCIG Groundwater monitoring program . POLLUTANT UNITS OF MEASURE FREQUENCY SAMPLING METHOD Aluminium milligrams per litre Every 6 months Grab sample Cobalt milligrams per litre Every 6 months Grab sample Copper milligrams per litre Every 6 months Grab sample Iron milligrams per litre Every 6 months Grab sample Magnesium milligrams per litre Every 6 months Grab sample Manganese milligrams per litre Every 6 months Grab sample Nickel milligrams per litre Every 6 months Grab sample Potassium milligrams per kilogram Every 6 months Grab sample Sodium milligrams per litre Every 6 months Grab sample Total PAHs micrograms per litre Every 6 months Grab sample Zinc milligrams per litre Every 6 months Grab sample pH pH Every 6 months Grab sample Table 7. Groundwater monitoring program default trigger values for the protection of aquatic ecosystems (ANZECC, 2000). DEFAULT TRIGGER VALUES PROTECTION LEVELS FOR AQUATIC ECOSYSTEMS TOXICANT 99% FRESH 95% 90% MARINE FRESH MARINE FRESH 80% MARINE FRESH MARINE Aluminium (Al) (g/L) 27 ID 55 ID 80 ID 150 ID Cobolt (Co) (g/L) ID 0.005 ID 1 ID 14 ID 150 Copper (Cu) (g/L) 1.0 0.3 1.4 1.3 1.8 3 2.5 8 Iron (Fe) (g/L) ID ID ID ID ID ID ID ID Magnesium (Mg) (g/L) ID ID ID ID ID ID ID ID Manganese (Mn) (g/L) 1200 80 1900 80 2500 80 3600 80 Nickel (Ni) (g/L) 8 7 11 70 13 200 17 560 Potassium (K) (g/L) ID ID ID ID ID ID ID ID Sodium (Na) (g/L) ID ID ID ID ID ID ID ID 1 1 1 Document No. Date Effective Review Date Page Number NCIG_HSEC_MPL_8.04 OWMP May 2010 May 2011 Page 19 of 26 1 NCIG OPERATION WATER MANAGEMENT PLAN Total PAHs(g/L) ID ID ID ID ID ID ID ID Zinc (Zn) (g/L) 2.4 7 8 15 15 23 31 43 Source: 1 ID: ANZECC (2000) Indicative interim working level. Insufficient Data. Table 8. Groundwater monitoring program default trigger values for the protection of aquatic ecosystems Physical and Chemical Stressors (ANZECC, 2000). PHYSICAL/CHEMICAL STRESSOR pH Specific Electrical Conductivity (EC) (S/cm) A B MARINE ESTUARIES 8.0 ‐ 8.4 7.0 ‐ 8.5 6.5 ‐ 8.5 ‐ ‐ 200‐300 (NSW coastal rivers) NSW LOWLAND RIVERS Source: ANZECC (2000) a Values for south‐east Australia. Values for NSW lowland rivers (<150 m altitude) in south‐east Australia. b 4.1.3 Stormwater and Pond Monitoring Parameters Stormwater from the rail infrastructure area is monitored at the water monitoring sites (Figure 4) for the parameters listed in Table 5. Stormwater from the coal storage area and wharf area are monitored at the secondary settling pond (Figure 4). Document No. Date Effective Review Date Page Number NCIG_HSEC_MPL_8.04 OWMP May 2010 May 2011 Page 20 of 26 NCIG OPERATION WATER MANAGEMENT PLAN Document No. Date Effective Review Date Page Number NCIG_HSEC_MPL_8.04 OWMP May 2010 May 2011 Page 21 of 26 NCIG OPERATION WATER MANAGEMENT PLAN Figure 4. Surface and groundwater monitoring sites for the NCIG site. Document No. Date Effective Review Date Page Number NCIG_HSEC_MPL_8.04 OWMP May 2010 May 2011 Page 22 of 26 NCIG OPERATION WATER MANAGEMENT PLAN In addition to the surface water monitoring described in Table 5, the Hunter Development Corporation (HDC) will continue to conduct surface water monitoring in accordance with Condition M2.1 of EPL No. 6437 for the Kooragang Island Waste Emplacement Facility. An outline of the HDC monitoring program is provided in Table 8. Table 8. HDC Surface Water Monitoring Program MONITORING LOCATIONS FREQUENCY 1 Surface water monitoring sites. Six monthly. PARAMETERS 4.1.4 Acenaphthene; Acenaphthylene; Anthracene; Benzo(a)anthracene; Benzo(a)pyrene; Benzo(b)fluoranthene; Benzo(k)fluoranthene; Benzo[ghi]perylene; Chromium (total); Chrysene; conductivity; Cyanide; Dibenz[a,h]anthracene; Fluoranthene; Fluorene; Indeno(1,2,3‐cd)pyrene; Iron; Lead; Manganese; Mercury; Molybdenum; Naphthalene; Nitrogen (ammonia); Phenanthrene; Phenol; Pyrene; total Polycyclic Aromatic Hydrocarbons; and pH. Erosion and Sediment Control Monitoring Monthly inspections of sediment control structures as well as inspections following significant rainfall events will be conducted by NCIG personnel. During these inspections, sediment control structures will be inspected for capacity, structural integrity and effectiveness. Results of inspections will be recorded in association with Erosion and Sediment Control Monitoring Checklists. 4.2 Data Review and Validation Water monitoring results are entered into a digital database by the Environmental Representative (or delegate) for comparison with preset water quality criteria on a weekly basis. Where monitoring results indicate values in excess of the relevant preset water quality criteria (Section 4), reporting procedures will be followed and data validation will be undertaken (i.e. examine the data to ascertain whether a false reading may have been obtained and obtain a repeat test, if practicable or required). Document No. Date Effective Review Date Page Number NCIG_HSEC_MPL_8.04 OWMP May 2010 May 2011 Page 23 of 26 NCIG OPERATION WATER MANAGEMENT PLAN Data producing values outside the acceptable levels that are deemed noncompliant will generate an internal nonconformance report for further action as per Section 4.3. 4.3 Investigation Procedures for Exceedance of Water Quality Criteria or Nonconformance Where monitoring results indicate values in excess of the water quality criteria described in Section 4.1, generation of nonconformance investigation procedures will be implemented by the Environmental Representative (or delegate). The investigation will commence as soon as practicable, generally on the same day as the completion of data validation or following the receipt of relevant environmental monitoring reports. The investigation will be conducted to review the potential causes of the exceedance and will include the following information: • • • • • If the values are inconsistent with baseline data (for example, in the event a water quality criteria is exceeded, a review of historic water quality data will be undertaken); If the impact is in excess of impacts predicted in the EA (NCIG, 2006); If any trends are evident in the data; and Consideration of the need to implement contingency measures in regards to the nonconformance documentation with the aim of creating corrective and preventative actions. Noncompliance reports and corrective and preventative actions recorded for NCIG internal and external reporting The investigation will involve the consideration of the monitoring results in conjunction with site activities being undertaken at the time, the prevailing and preceding meteorological conditions and any changes to activities being undertaken in the vicinity. If considered appropriate, the investigation may involve the engagement of relevant specialists (e.g. hydrologists). The results of any such investigations will be summarised in the Annual Environmental Management Report (AEMR) and also form part of the EPA reporting requirements as per EPL No. 12693 and the Director Generals Requirements 5 CORRECTIVE ACTIONS If following the above assessment the exceedance of the applicable trigger levels is determined to be due to operational or construction update activities, the Environmental Representative will determine appropriate management strategies and implementation of contingency measures in consultation with the relevant operations manager. These will be in addition to those implemented as part of normal operational activities (including modifications to operational methodologies, if necessary). 6 REPORTING NCIG reporting will involve procedures for reporting incidents and complaints. Internal reports will be generated on a monthly basis. External reports will comply with statutory and operational requirements. 6.1 Incident Reporting Any incident which occurs within the NCIG footprint or which is deemed to be associated with the activities of NCIG must be documented and reported by the employee or NCIG agent/contractor who has been associated or witnessed the incident. The method for reporting the incident is through the NCIG Incident Report Protocol. 6.2 Recording Pollutant Complaints In accordance with EPL No. 12693 NCIG must keep a record of any complaint made to NCIG, any employee of NCIG or any agent of NCIG in relation to pollution arising from NCIG activities. Record must include: • Date and time of complaint Document No. Date Effective Review Date Page Number NCIG_HSEC_MPL_8.04 OWMP May 2010 May 2011 Page 24 of 26 NCIG OPERATION WATER MANAGEMENT PLAN • • • • • Method by which complaint was made Personal details from the complaint Nature of the complaint Action taken by NCIG and any follow up If no action taken, the reason why no action was taken 6.3 Internal Reporting Internal reports will be undertaken to provide a mechanism for regular feedback and analysis of the effectiveness of the operation’s Water Management system and controls. This will help to identify any potential levels of risk, or potential system and operational improvements relating to water assets and compliance. 6.4 External Reporting/Notification In terms of external reporting and in accordance with Condition 8.1, Schedule 2, of the Project Approval (06_0009), the Director‐General will be notified of any incident with actual or potential significant off‐site impacts on people or the biophysical environment as soon as practicable after the occurrence of the incident. The Director‐General will be provided with written details of the incident within seven days of the date on which the incident occurred. In accordance with EPL No. 12693 NCIG must supply the EPA an Annual Return comprising of: • • a Statement of Compliance a Monitoring Complaints Summary NCIG must notify the EPA of any incidents causing or threatening material harm to the environment, by telephone on the day of the incident and written details within seven days. NCIG will prepare an AEMR that reviews the performance of the operations against this OWMP, provides an overview of environmental management actions and summarises monitoring results over the 12 month reporting period. The AEMR will be distributed to relevant government agencies and stakeholders, and copies provided to other interested parties if requested. In accordance with Condition 6.4, Schedule 2 of Project Approval (06_0009), this OWMP will be made available on the NCIG website. 7 AUDIT AND REVIEW 7.1 Audits The Environmental Manager (or delegate) is to audit the conduct of activities associated with the OWMP on a quarterly basis and submit a formal report to the General Manager. This audit is to address the following issues as a minimum: • • • • • Record keeping Inspections Reports Methods of work Incidents and nonconformance reporting 7.2 Review Process The OWMP will be reviewed on an annual basis and will also be updated as an active document between reviews as required. Annual and active reviews will reflect operational changes, infrastructure modifications, updated regulatory regulations and requirements and incident actions. Document No. Date Effective Review Date Page Number NCIG_HSEC_MPL_8.04 OWMP May 2010 May 2011 Page 25 of 26 NCIG OPERATION WATER MANAGEMENT PLAN 8 REFERENCES 1. Australian Government (2000), Australian and New Zealand Guidelines for Fresh and Marine Water Quality. 2. Department of Infrastructure, Planning and Natural Resources (2004) Guidelines for the Preperation of Environmental Management Plans. 3. Landcom (2004) Managing Urban Stormwater: Soils and Construction. 4. Newcastle Coal Infrastructure Group (NCIG) (2006) Newcastle Coal Infrastructure Group Coal Export Terminal Environmental Assessment. 5. Newcastle Coal Infrastructure Group (NCIG) (2007) Newcastle Coal Infrastructure Group Coal Export Terminal – Kooragang Island Construction Surface Water Management Plan. 6. New South Wales Government (2007), Project Approval 06_0009. Document No. Date Effective Review Date Page Number NCIG_HSEC_MPL_8.04 OWMP May 2010 May 2011 Page 26 of 26