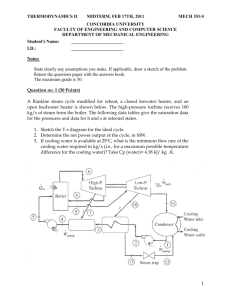

Systems Guide

advertisement