Retrofit - Gaylord Ventilation

advertisement

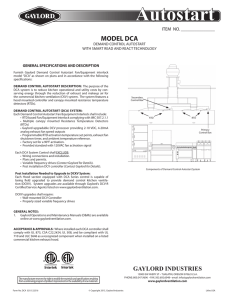

DCV-R Retrofit ITEM NO. _______________ MODEL “DCV-R” DEMAND CONTROL VENTILATION WITH SMART READ AND REACT TECHNOLOGY Standard DCV Control Cabinet GENERAL SPECIFICATIONS AND DESCRIPTION Furnish Gaylord Demand Control Ventilation (DCV) with smart read and react technology Model “DCV-R” as shown on plans and in accordance with the following specifications: DCV-R SMART READ AND REACT DEMAND CONTROL VENTILATION SYSTEM: The purpose of a demand control ventilation system is to save energy, reduce operational costs, and optimize HVAC efficiencies for a commercial kitchen ventilation (CKV) system. The system modulates based on the equipment operation, activity level and the ambient room temperature. The system also includes provisions to automatically activate the exhaust fan complying with IMC 507.2.1.1 and will automatically shut down once daily cooking operations have ended unless the exhaust fan is manually activated. The DCV-R Smart Read and React Technology requires multiple resistance temperature devices (RTD’s) mounted inside the hood canopy section to accurately read and react to the thermal plume generated from the cooking equipment and the activity level of the chef to regulate ventilation rates. Height The DCV-R System utilizes Gaylord’s patent-pending customizable algorithms that can be adjusted specifically for the cooking equipment under each hood section. Each algorithm is set during the commissioning process allowing the system to be fully customized for each individual cook line providing maximum energy saving for the end user. The DCV-R Smart Read and React Demand Control Ventilation System shall include: • One (1) processor board for each hood section mounted in a DCV Control Cabinet at the end of the hood or in the kitchen within 50 feet of the hood. Each DCV Control Cabinet can control up to four (4) exhaust fans and up to six (6) hood sections. • A maximum of three (3) resistance temperature devices (RTD’s) will be provided in each wall hood canopy section. A maximum of four (4) RTD’s will be provided in each island hood canopy section. • One (1) RTD shall be installed in each exhaust duct collar. • Multi-conductor cabling to be provided by Gaylord to connect the resistance temperature device (RTD) sensors in the hood to the DCV Control Cabinet. • Each system will include one (1) room ambient temperature sensor per exhaust fan. The room temperature sensor will work together with the hood resistance temperature devices (RTD’s) to provide an intelligent read and react process to minimize exhaust volumes while maintaining capture and containment. • A 100% Fan Override button will be provided to send the fan(s) to 100% for five (5) minutes in the event the user wishes to increase the ventilation rate. The 100% Fan Override button will be on the face of the DCV Control Cabinet and needs to be mounted in the kitchen within 50 feet of the exhaust hood by an Electrician. • A Fan Start/Stop button will be provided if needed to turn on the exhaust fan(s) to a minimum set point and turn off the fan(s) when conditions allow. The Fan Start/Stop button will be on the face of the DCV Control Cabinet and needs to be mounted in the kitchen within 50 feet of the exhaust hood by an Electrician. • Upon hood activation, the controller shall close a set of dry contacts sending the system to its minimal exhaust rate where a 4 to 20 mA signal will modulate the exhaust rate between the minimum and maximum set points. • Wiring to the Variable Frequency Drives (VFD’s) and/or Building Management System (BMS) by others. • The System will comply with IMC 507.2.1.1. Exhaust Fan Start/Stop Button 100% Fan Button Cabinet (Height x Depth x Width) Number Of Hood Sections Height In Inches 1-2 25 3-4 36 5-6 40 Cabinet Depth: 7” or 8” Note: If the DCV Control Cabinet is recessed mounted, a 1-1/2” stainless steel trim ring (not illustrated) is supplied. DCV- R RETROFIT DCV-R PROGRAMMING SPECIFICATIONS: Gaylord provides a programming specification for the following configurations: Option 1 Exhaust and Supply fan(s) VFD by Gaylord Option 2 Exhaust and Supply fan(s) VFD by others. Gaylord will provide a programming specification for other Variable Frequency Drives (VFD’s) GENERAL NOTES: 1. No substitution of Gaylord components allowed except cables. 2. All motors must be inverter rated as specified in NEMA Std. 1, part 31. 3. Confirm there is access to the top of the hood to install the canopy temperature sensors (RTD’s) and wiring. Contact a Gaylord CSA Representative for additional details if required. 4. Gaylord CSA is responsible for coordinating high voltage wiring connections, conduit, providing or pulling low voltage wiring, control cable, running of the Gaylord sensor or VFD cabling, and any conduit, ceiling or wall penetrations. 5. Minimum air flows are to be set for a maximum turndown with the Test Balance Technician responsible for any necessary field adjustments to fan sheaves. 6. ETL Certified to UL 508A, UL 710. 7. Gaylord Operation Maintenance Manuals (O&M’s) are available online at www.gaylordventilation.com. SEQUENCE OF OPERATION: See Gaylord Technical Manual. CAPTURE AND CONTAINMENT: Shall be per ASHRAE STD 154. CONSTRUCTION: The DCV Control Cabinet housing shall be constructed of 300 series stainless steel with a #4 finish complying with NSF/ ANSI 2-2010. The resistance temperature device (RTD) exterior shall be constructed of stainless steel. ACCEPTANCE & APPROVALS: DCV System will comply with current IMC 507.2.1.1. The DCV Control shall be listed to UL 508A. The DCV Control Cabinet shall be compliant with NSF Standard No. 2. The sensors shall be ETL Listed recognized components to UL 710 when installed in a Listed hood. The VFD drive assembly, if provided by Gaylord, shall have an open type industrial control listing to UL 508A. Resistance Temperature Devices (RTD’s) Resistance Temperature Devices (RTD’s) GAYLORD INDUSTRIES The manufacturer reserves the right to modify the materials and specifications resulting from a continuing program of product improvement or the availability of new materials. 10900 SW AVERY ST • TUALATIN, OREGON 97062 U.S.A. PHONE: 800.547.9696 • FAX: 503.692.6048 • email: info@gaylordventilation.com www.gaylordventilation.com Form No. DCVR-1112-21921 © Copyright 2012, Gaylord Industries Litho USA