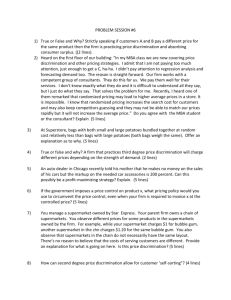

Toyota in Europe - toyota uk media site

advertisement